Waterborne epoxy colorful floor paint and colored waterborne epoxy resin gel particle

A water-based epoxy resin, epoxy colorful technology, applied in the direction of epoxy resin coating, synthetic resin layered products, coatings, etc., can solve the problems of increasing the difficulty of construction, high price, and failure to achieve the effect of granite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1 waterborne epoxy colorful floor paint (one)

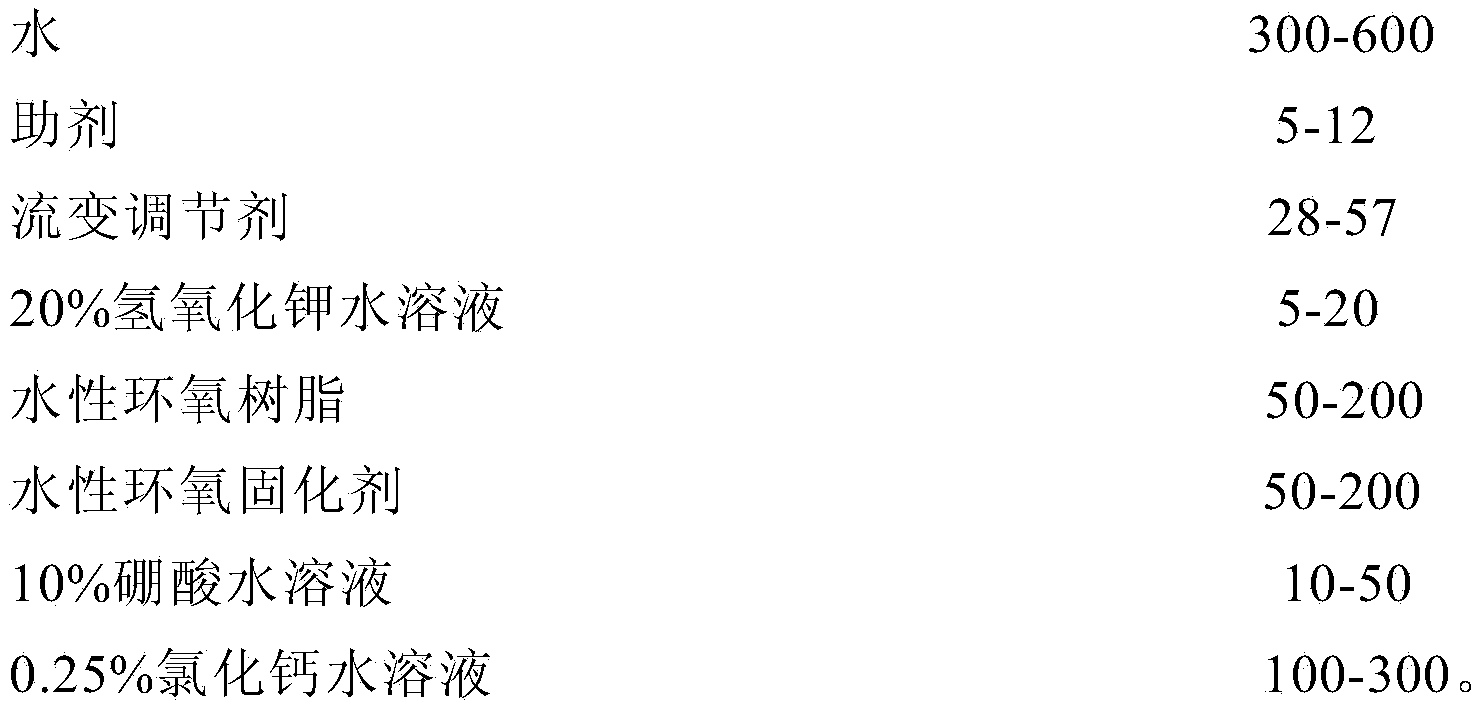

[0047] (1) The ratio of each raw material component, by weight ratio:

[0048] Table 1

[0049] water

455

4

D

2

4

carbomer

5

4% konjac aqueous solution

50

20% potassium hydroxide aqueous solution

10

Epoxy resin E-51

100

Waterborne epoxy curing agent

100

10% boric acid aqueous solution

20

0.25% calcium chloride aqueous solution

250

[0050] (2) Preparation of colored water-based epoxy resin gel particles

[0051] Step 1: Put water, wetting agent, defoamer, bactericide, carbomer, and konjac aqueous solution into a high-speed disperser at 1000 rpm and stir for 10-15 minutes to disperse.

[0052] Step 2: Add potassium hydroxide solution dropwise for neutralization, so that the pH value reaches 8.

[0053] Step 3: Use color paste to color, vacuumize to eliminate air...

Embodiment 2

[0062]Embodiment 2, waterborne epoxy colorful floor paint (two)

[0063] (1) The ratio of each raw material component, by weight ratio:

[0064] Table 2

[0065] water

505

4

D

2

4

carbomer

5

4% konjac aqueous solution

50

20% potassium hydroxide aqueous solution

10

Epoxy resin E-51

75

Waterborne epoxy curing agent

75

10% boric acid aqueous solution

20

0.25% calcium chloride aqueous solution

250

[0066] (2) Preparation of colored water-based epoxy resin gel particles

[0067] Step 1: Put water, wetting agent, defoamer, bactericide, carbomer, and konjac aqueous solution into a high-speed disperser at 1500 rpm and stir for 10-15 minutes to disperse.

[0068] Step 2: Add potassium hydroxide solution dropwise for neutralization, so that the pH value reaches 8.

[0069] Step 3: Toning, vacuuming to eliminate air bubbles; forming a ...

Embodiment 3

[0078] Embodiment 3, waterborne epoxy colorful floor paint (three)

[0079] (1) The ratio of each raw material component, by weight ratio:

[0080] table 3

[0081] water

405

4

D

2

4

carbomer

5

4% konjac aqueous solution

50

20% potassium hydroxide aqueous solution

10

Epoxy resin E-51

125

Waterborne epoxy curing agent

125

10% boric acid aqueous solution

20

0.25% calcium chloride aqueous solution

250

[0082] (2) Preparation of colored water-based epoxy resin gel particles

[0083] Step 1: Put water, wetting agent, defoamer, bactericide, carbomer, and konjac aqueous solution into a high-speed disperser at 2000 rpm and stir for 10-15 minutes to disperse.

[0084] Step 2: Add potassium hydroxide solution dropwise for neutralization, so that the pH value reaches 8.

[0085] Step 3: Toning, vacuuming to eliminate air bubbles; formi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com