Solvent-free non-yellowing type polyurethane adhesive for sport field

A technology for polyurethane adhesives and sports venues, applied in the direction of polyurea/polyurethane adhesives, adhesive types, non-polymer adhesive additives, etc., can solve low reactivity, poor strength, adhesive storage Reduced stability and other issues, to achieve the effect of good storage stability, simple preparation method, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

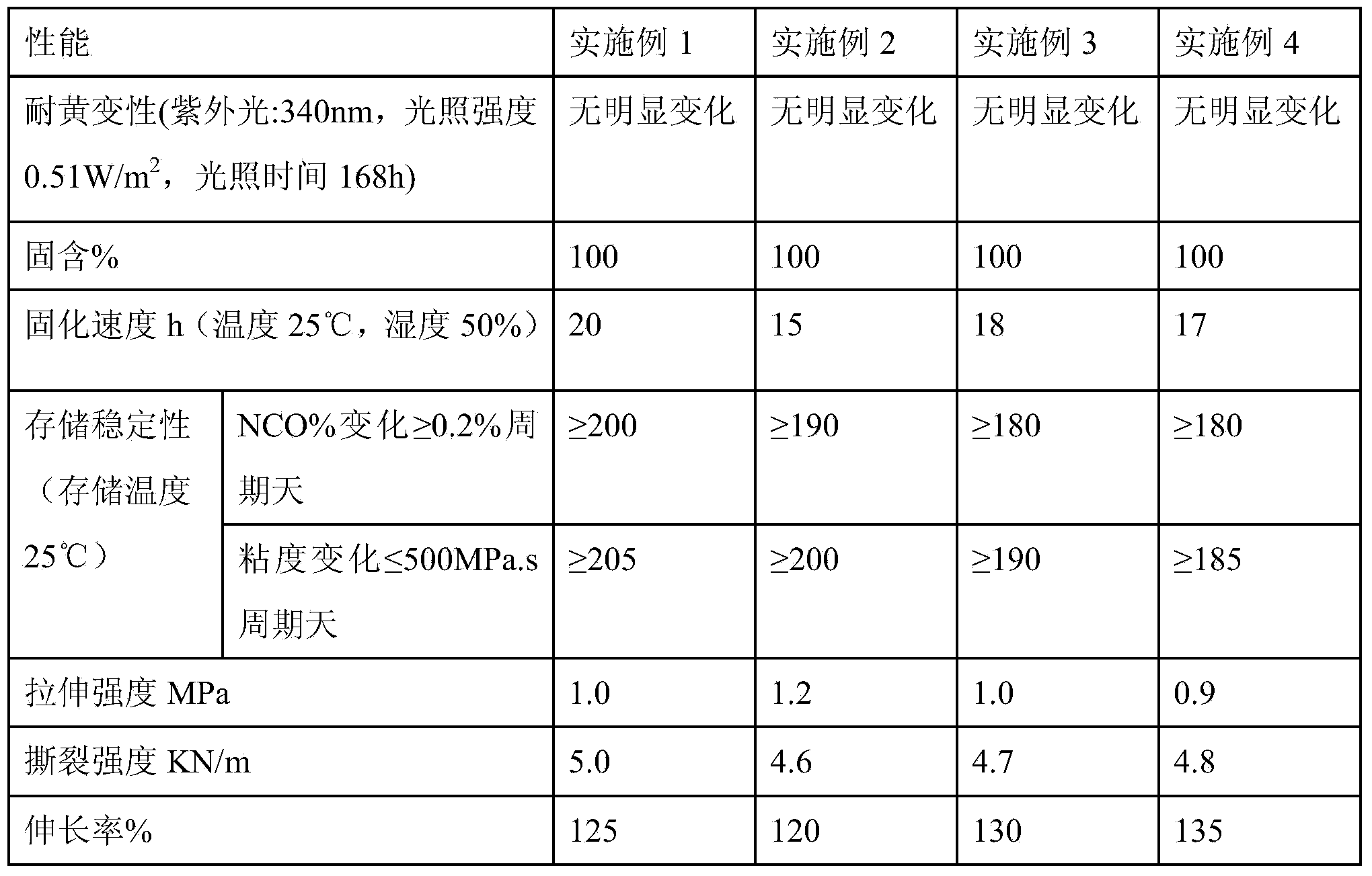

Examples

Embodiment 1

[0021] The polyolefin polyol (with H 2 O 2 As the initiator, 1,2 propylene glycol is used as the solvent, butadiene undergoes free radical polymerization, the molecular weight is 1000, the functionality is 2) 25 grams, and the polyolefin polyol (with H 2 O 2 As the initiator, 1, 2 propylene glycol is used as the solvent, butadiene undergoes free radical polymerization, the molecular weight is 2000, the functionality is 2) 15 grams, and 30 grams of castor oil is added to the reactor at room temperature, and the temperature is raised to 97°C and stirred. The pressure is -0.095MPa for dehydration and degassing for 2.5 hours. When the water content is less than 0.05%, the temperature is reduced to 88°C and 20 grams of 1,4-cyclohexane diisocyanate and 5 grams of cyclohexane dimethylene diisocyanate are added. React at 85°C for 2.5 hours, add 1 g of 3,5-tert-butyl-4-hydroxyphenylpropionic acid isooctyl ester, bis(2,2,6,6-tetramethyl-4-piperidinyl)sebacic acid 3 grams of ester, 0.8 gra...

Embodiment 2

[0024] The polyolefin polyol (with H 2 O 2 As the initiator, 1, 2 propylene glycol is used as the solvent, butadiene undergoes free radical polymerization, the molecular weight is 1000, the functionality is 2) 30 grams, and 30 grams of castor oil is added to a three-necked flask at room temperature. The temperature is raised to 95°C and stirred. The pressure is -0.095MPa for dehydration and degassing for 3 hours. When the water content is less than 0.05%, the temperature is lowered to 90°C and 30 grams of 1,4-cyclohexane diisocyanate is added. The reaction is carried out at 80°C for 3 hours and 3,5-tert is added. 4 grams of isooctyl butyl-4-hydroxyphenylpropionate, 4 grams of bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate, 2 grams of bismuth isooctanoate, cool to Bottling at 15°C.

[0025] When in use, the glue and TPU / EPDM particles are mixed in a ratio of 1:5.

Embodiment 3

[0027] The polyolefin polyol (with H 2 O 2 As the initiator, 1,2 propylene glycol is used as the solvent, butadiene undergoes free radical polymerization, the molecular weight is 1000, the functionality is 2) 35 grams, 25 grams of castor oil is added to a three-necked flask at room temperature, and the temperature is raised to 100 ℃ and stirred, ( The pressure is -0.095MPa) dehydration and degassing for 2 hours, when the water content is less than 0.05%, the temperature is lowered to 90℃, 30 grams of 1,4-cyclohexane diisocyanate and 5 grams of isophorone diisocyanate are added and reacted at 83℃ In 2.7 hours, add 3 grams of 3,5-tert-butyl-4-hydroxyphenylpropionic acid isooctyl ester and 1 grams of bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate , 0.65 grams of bismuth isooctanoate, 0.35 grams of N-ethylmorpholine, and bottle at 15℃.

[0028] When using, mix the glue with TPU / EPDM particles in a ratio of 1:7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com