Radiopaque polymer and preparation method and application thereof

A technology of polymers and compounds, applied in the field of radiopaque polymers and their preparation, can solve the problems of lack of clinical conditions for treatment, fragile precipitation, high mechanical properties, etc., achieve long-term developing effects, not easy to biodegrade, and moderate curing speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

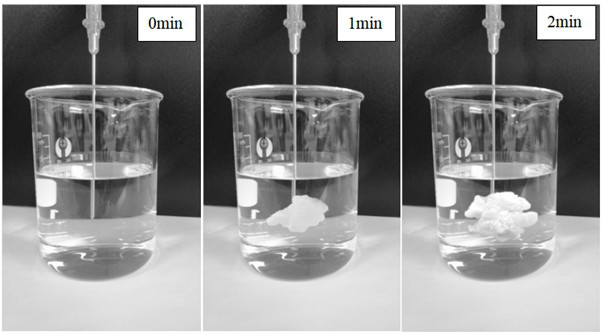

[0040] The present invention designs a kind of opaque polymer, which is obtained by the following preparation method, and the method mainly comprises the following steps:

[0041] Step 1, dissolving polyvinyl alcohol in water, adding an alkaline catalyst and epichlorohydrin, and reacting at a temperature of 50-95° C. for 5-50 min to obtain activated polyvinyl alcohol;

[0042] Step 2: Dissolving the activated polyvinyl alcohol obtained in step 1 in a polar aprotic solvent, adding an alkali compound and an iodobenzyl alcohol compound, and reacting at a temperature of 90-200° C. for 1-12 hours to obtain a radiopaque polymer.

[0043] In the present invention, the polyvinyl alcohol is activated by grafting epichlorohydrin onto the polyvinyl alcohol under the condition of a basic catalyst, and then the iodobenzyl alcohol compound is grafted onto the activated polyvinyl alcohol through an etherification reaction to obtain a Transmissive polymer. Compared with other existing graft ...

Embodiment 1

[0086] (1) Preparation of activated polyvinyl alcohol

[0087]

[0088] Add 100g of purified water and 10g of polyvinyl alcohol with a weight average molecular weight of 13000 (-OH0.227mol) into the reaction flask, heat to 90°C to completely dissolve the polyvinyl alcohol, when the solution has no precipitation and a transparent color, it is completely dissolved;

[0089] Put 22g epichlorohydrin (0.238mol) and 0.5g catalyst NaOH into the reactor, react at 75°C, slowly drop the reaction solution into a beaker containing methanol precipitant, and stir with a glass rod while adding dropwise. , the precipitated white flocculent precipitate was repeatedly filtered and washed with methanol for three times, and then dried to constant weight at 50-60° C. to obtain activated polyvinyl alcohol (ECH-PVA).

[0090] (2) Preparation of opaque polymers

[0091]

[0092] Under nitrogen flow, the activated polyvinyl alcohol obtained in step (1) was dissolved in 100 ml of anhydrous NMP. T...

Embodiment 2

[0095] (1) Add 100g purified water and 10g polyvinyl alcohol (-OH 0.227mol) with a weight average molecular weight of 13000 to the reaction bottle, heat to 90°C to completely dissolve the polyvinyl alcohol, and dissolve when the solution has no precipitation and a transparent color. completely;

[0096] Put 11g epichlorohydrin (0.119mol) and 0.5g catalyst NaOH into the reactor, react at 75°C, slowly drop the reaction solution into a beaker containing methanol precipitant, and stir with a glass rod while adding dropwise. , the precipitated white flocculent precipitate was repeatedly filtered and washed with methanol for three times, and then dried to constant weight at 50-60° C. to obtain activated polyvinyl alcohol (ECH-PVA).

[0097] (2) Under nitrogen flow, the activated polyvinyl alcohol obtained in step (1) was dissolved in 100 ml of anhydrous NMP. The reaction mixture was stirred at 130°C for 5 minutes; the temperature was then lowered to 50°C. 55 g of 2,3,5-iodobenzyl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com