Method for preparing titanium oxide ceramic coating on lead alloy surface

A technology of ceramic coating and lead alloy, applied in the direction of electrolytic inorganic material plating, etc., to achieve the effect of reducing the precipitation of lead ions, reducing the precipitation of lead ions, and delaying corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

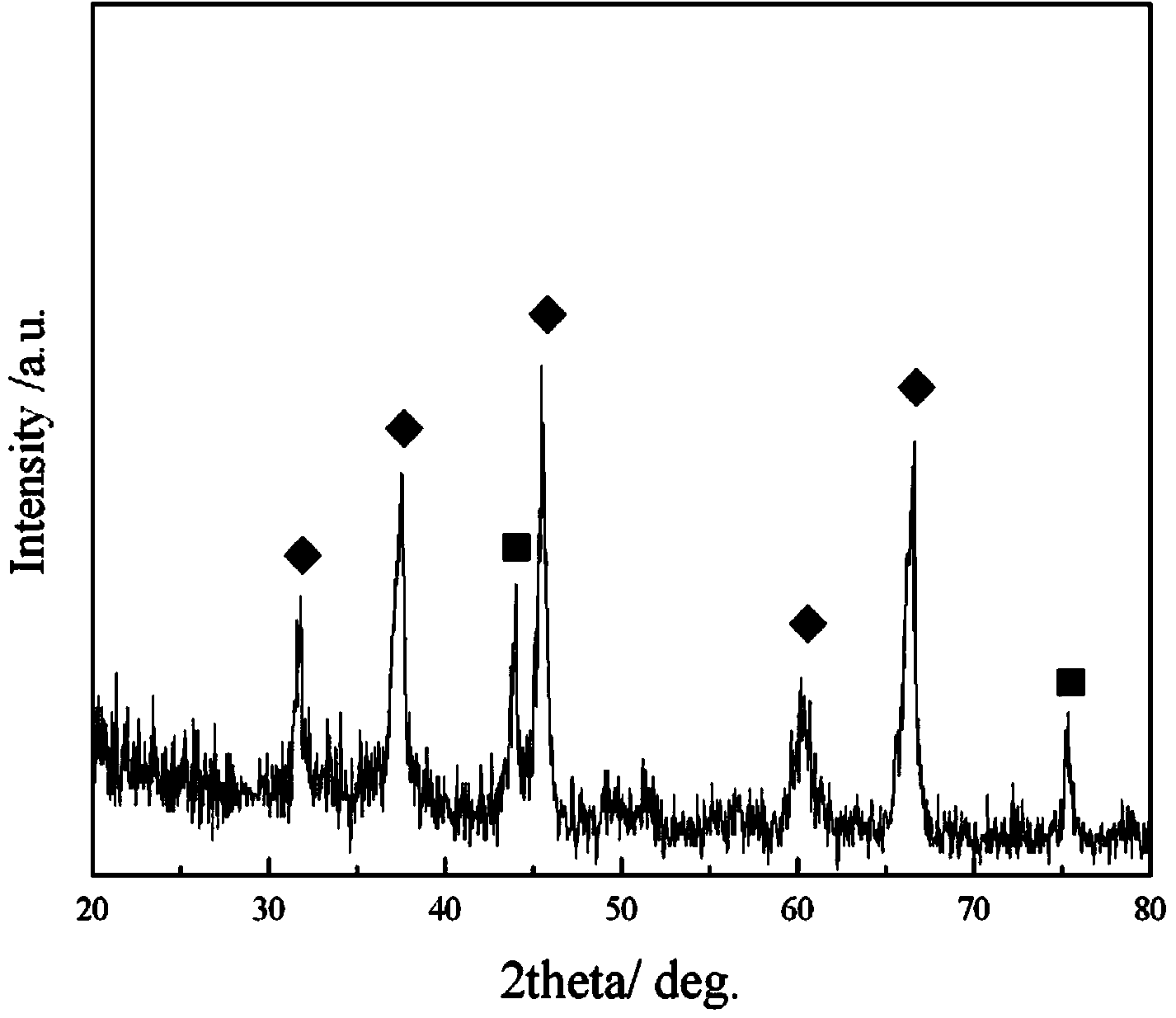

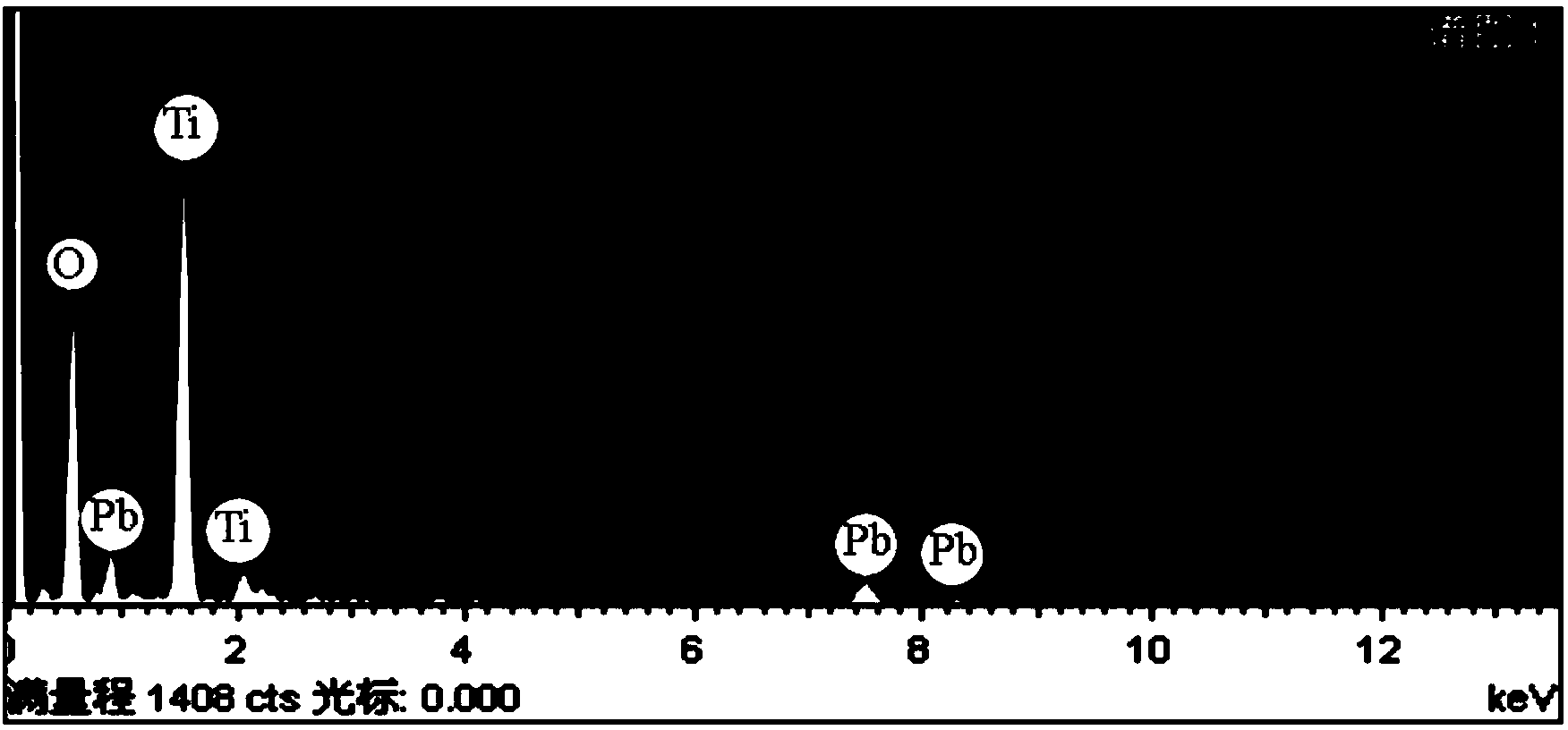

Image

Examples

Embodiment 1

[0026] In this embodiment, the method for preparing a titanium oxide ceramic coating on the surface of a lead alloy of the present invention comprises the following steps:

[0027] (1) Firstly, the lead alloy with an antimony mass fraction of 3% was polished with sandpaper to remove the surface scale, and then ultrasonically cleaned in acetone for 6 minutes;

[0028] (2), 15g / L cerium chloride was dissolved in distilled water to prepare a solution;

[0029] (3) Place the lead alloy treated in step (1) in the solution prepared in step (2), heat it to 60°C in a water bath, and process for 3 hours to prepare a chemical conversion film on the surface of the lead alloy;

[0030] (4) According to the concentration of tetrabutyl titanate of 15g / L and the concentration of additives of 3g / L dissolved in alcohol, the electrolyte solution was prepared;

[0031] (5), place the lead alloy treated in step (3) in the stainless steel tank with the electrolyte prepared in step (4), use lead a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com