Preparation method of magnetic control induced amaranth molecular targeted electrochemical sensing membrane

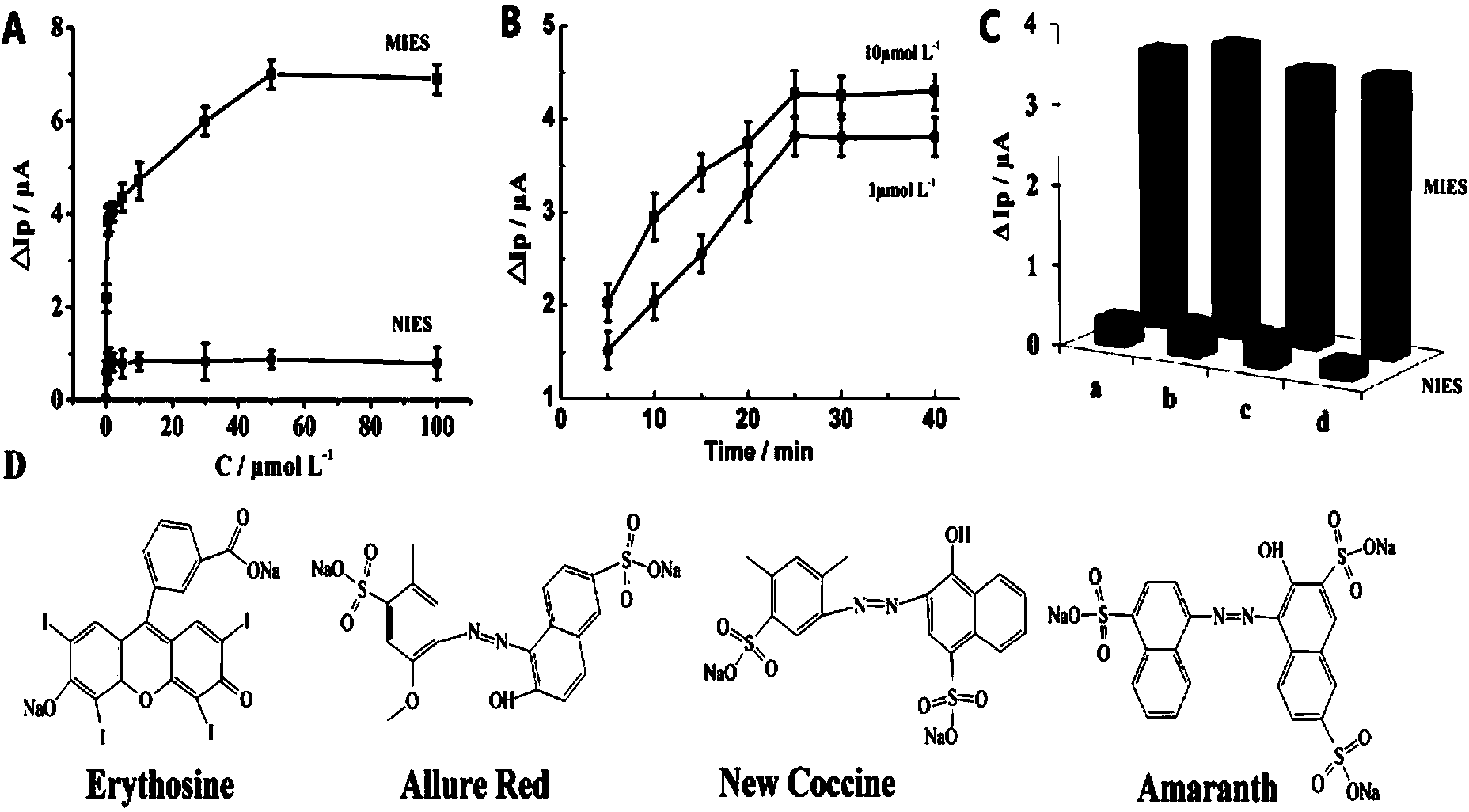

A molecular targeting, amaranth technology, applied in the field of analysis and detection, can solve problems such as affecting the sensitivity of sensors, and achieve the effects of improving detection sensitivity, good sensitivity, and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] (1) Glassy carbon electrode pretreatment

[0048] Magnetic glassy carbon electrode (Φ=3mm) through 0.05μm Al 2 o 3 After the suspension was polished, it was rinsed with double distilled water, then ultrasonically cleaned with absolute ethanol and deionized water for 1 min, and the electrode was further dried with nitrogen after cleaning.

[0049] (2) Molecularly imprinted self-assembly solution:

[0050] Prepared with 0.4mg / mLFe 3 o 4 RGO, 120mmol / L sulfuric acid, 2.4mg / mL amaranth red NaAc-HAc buffer solution (pH4.5), deoxygenated with nitrogen, sealed, placed in a dark environment at 20°C to 30°C for 2h, added 60mmol / L aniline was used as a cross-linking agent, sealed and stirred for 1 hour to obtain a molecularly imprinted self-assembly solution.

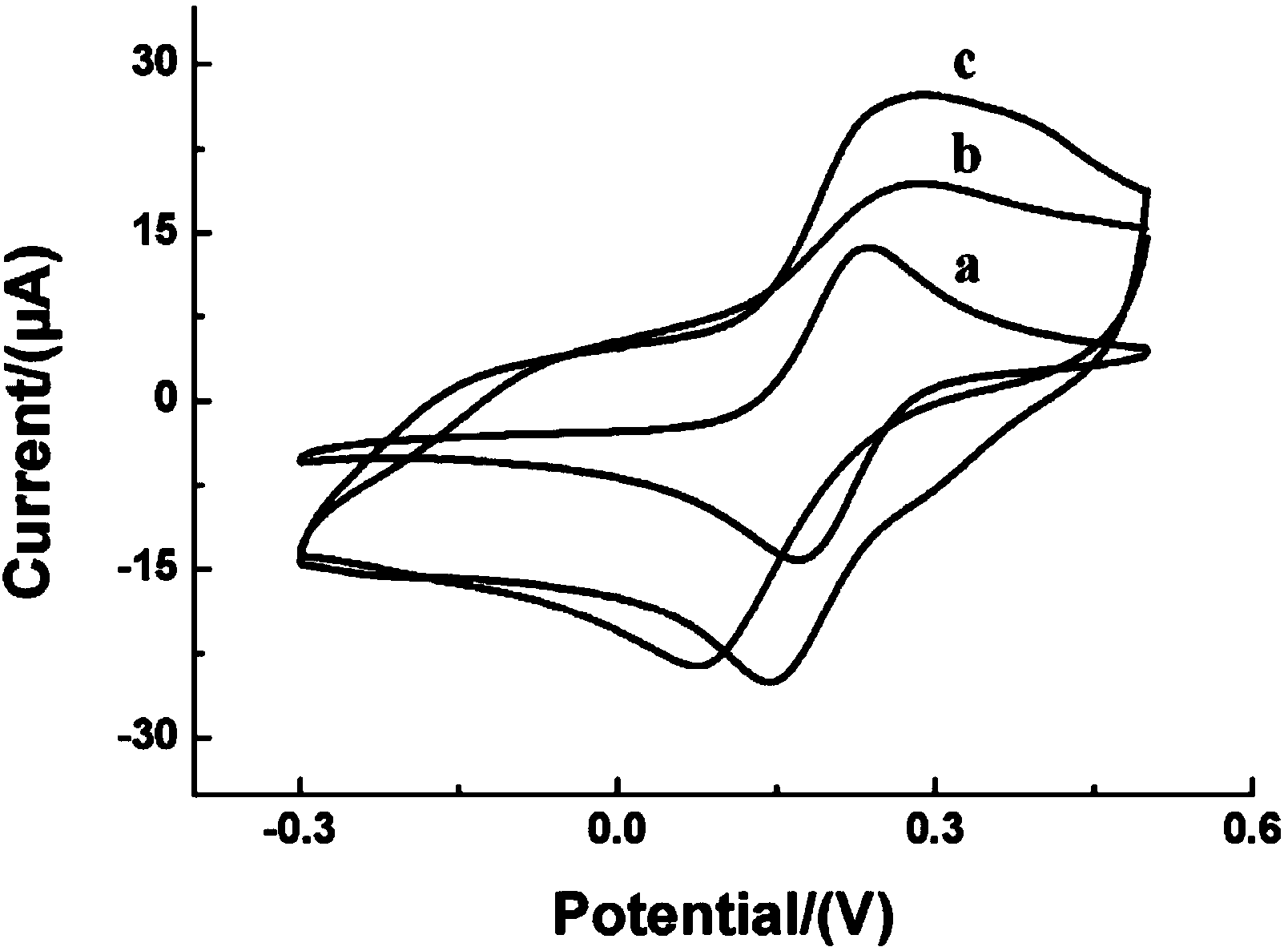

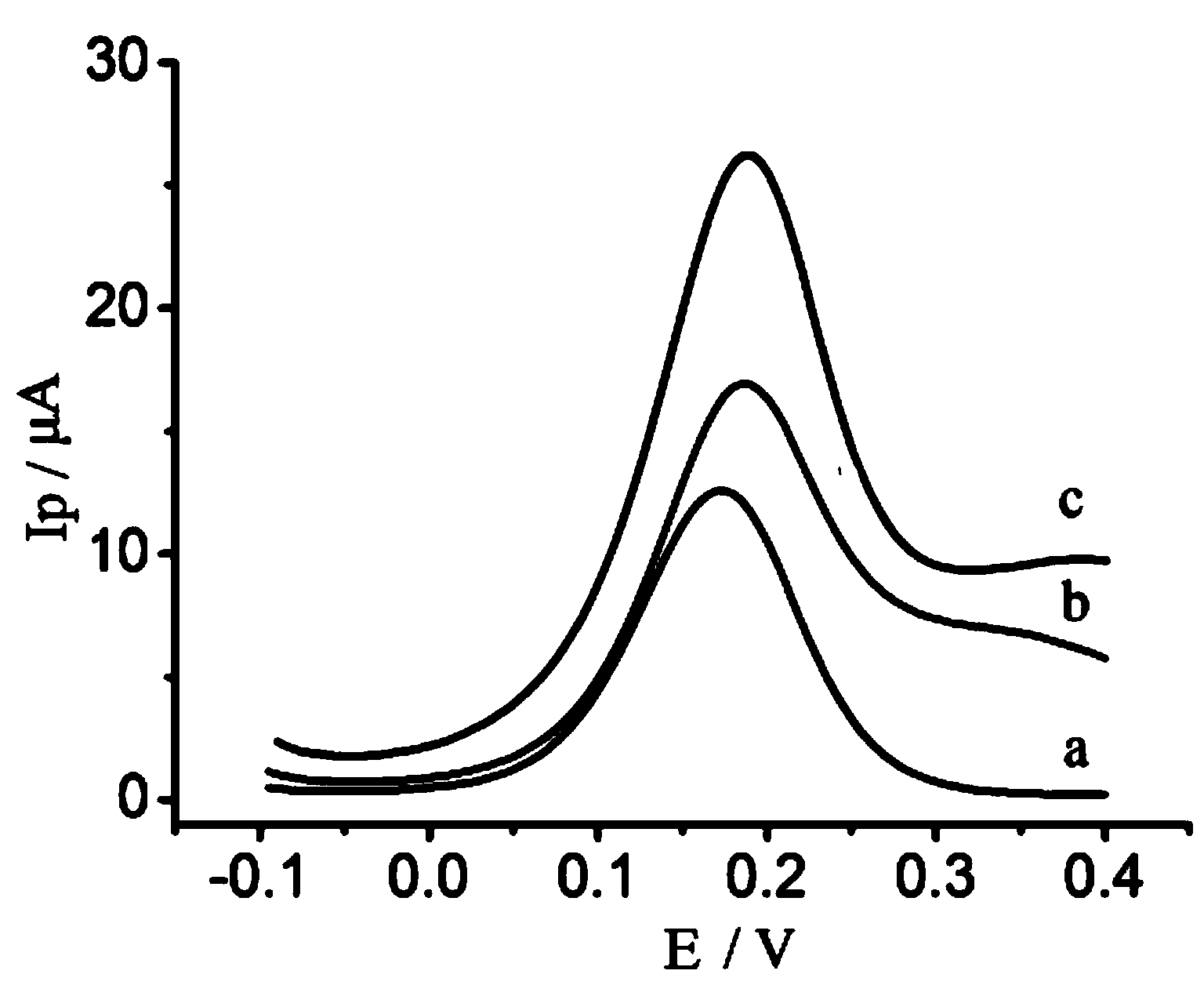

[0051] (3) Electropolymerization reaction:

[0052] Pour the molecularly imprinted self-assembly solution into a reaction container, keep away from light, and pass nitrogen gas, insert the magnetic glassy carbon ele...

Embodiment example 2

[0056] (1) Glassy carbon electrode pretreatment

[0057] Magnetic glassy carbon electrode (Φ=3mm) through 0.05μm Al 2 o 3 After the suspension was polished, it was rinsed with double distilled water, then ultrasonically cleaned with absolute ethanol and deionized water for 1 min, and the electrode was further dried with nitrogen after cleaning.

[0058] (2) Molecularly imprinted self-assembly solution:

[0059] Prepared with 0.5mg / mLFe 3 o 4 RGO, 150mmol / L sulfuric acid, 3.0mmol / L amaranth red NaAc-HAc buffer solution (pH5.8), deoxygenated with nitrogen, sealed, placed in a light-proof environment at 20-30°C for 5 hours, and added 60mmol / L Aniline was used as a cross-linking agent, sealed, and continued to stir for 1 hour to obtain a molecularly imprinted self-assembly solution.

[0060] (3) Electropolymerization reaction:

[0061] Pour the molecularly imprinted self-assembly solution into the reaction container, keep away from light, and pass nitrogen gas, then insert t...

Embodiment example 3

[0065] (1) Glassy carbon electrode pretreatment

[0066] Magnetic glassy carbon electrode (Φ=3mm) through 0.05μm Al 2 o 3 After the suspension was polished, it was rinsed with double distilled water, then ultrasonically cleaned with absolute ethanol and deionized water for 1 min, and the electrode was further dried with nitrogen after cleaning.

[0067] (2) Molecularly imprinted self-assembly solution:

[0068] Prepared with 0.8mg / mLFe 3 o 4 RGO, 200mmol / L sulfuric acid, 1.5mg / mL amaranth red NaAc-HAc buffer solution (pH6.0), deoxygenated with nitrogen, sealed, placed in a dark environment at 20°C to 30°C for 2h, added 80mmol / L aniline was used as a cross-linking agent, sealed and stirred for 1 hour to obtain a molecularly imprinted self-assembly solution.

[0069] (3) Electropolymerization reaction:

[0070] Pour the molecularly imprinted self-assembly solution into the reaction container, keep away from light, and pass nitrogen gas, insert the magnetic glassy carbon e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com