Method for preparing nano palladium metal catalyst

A technology of metal catalysts and nano-palladium, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as complex processes and unfavorable large-scale production, and achieve Easy to recover, not easy to deactivate, high activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

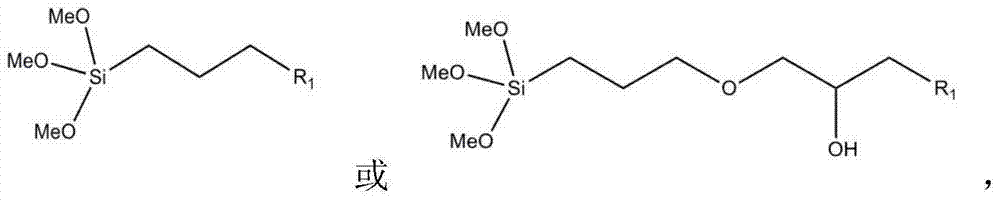

Method used

Image

Examples

Embodiment example 1

[0019]

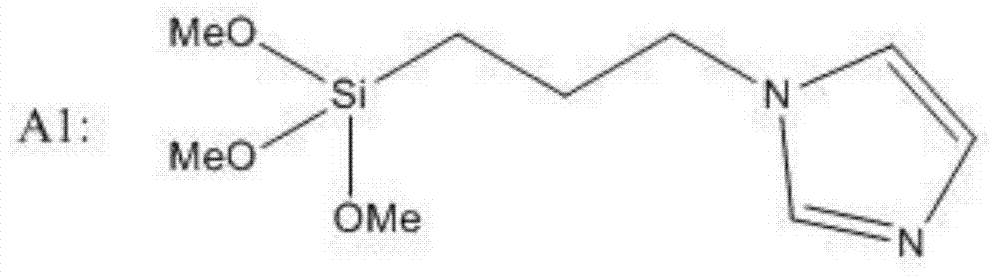

[0020] Under an argon atmosphere, weigh 0.2g functional additive A1 and dissolve it in 4mL of toluene, stir for 30min, then add 0.8g SiO 2 (Specific surface is 420m 2 / g), stirred at 80°C for 4h, cooled to room temperature, and then added 1mL of Pd(OAc) with a concentration of 0.02g / mL 2 Toluene solution, stirred at 80°C for 6h, filtered, washed the filter cake with toluene, dried the filter cake under vacuum at room temperature, and reduced it under hydrogen atmosphere at 200°C for 3h, added 4mL of toluene to the solid obtained above, and then added 0.1g tetraethyl orthosilicate, Stir at 50°C for another 10h, filter, wash the filter cake with toluene, and vacuum-dry the filter cake at 50°C for 20h to obtain the final catalyst C1.

Embodiment example 2

[0022] Under an argon atmosphere, weigh 0.3g functional additive A1 and dissolve it in 4mL of toluene, stir for 30min, then add 0.7g SiO 2 (Specific surface is 420m 2 / g), stirred at 80°C for 4h, cooled to room temperature, and then added 0.5mL of Pd(OAc) with a concentration of 0.02g / mL 2 Toluene solution, stirred at 50°C for 6h, filtered, washed the filter cake with toluene, dried the filter cake under vacuum at room temperature, and reduced it under hydrogen atmosphere at 200°C for 3h, added 4mL of toluene to the solid obtained above, and then added 0.1g tetraethyl orthosilicate, Stir at 50°C for another 8h, filter, wash the filter cake with toluene, and vacuum-dry the filter cake at 50°C for 20h to obtain the final catalyst C2.

Embodiment example 3

[0024]

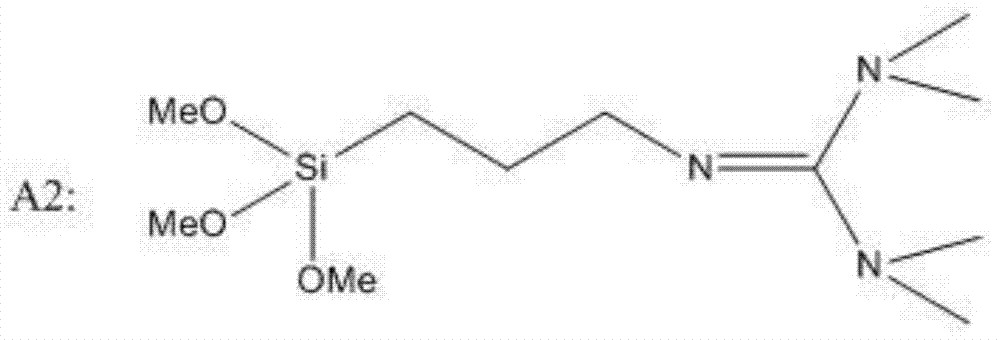

[0025] Under an argon atmosphere, weigh 0.1g of functional aid A2 and dissolve it in 4mL of methanol, stir for 30min, then add 0.9g of treated SiO 2 (Specific surface is 420m 2 / g), after stirring at 25°C for 48h, add 0.5mL of Pd(OAc) with a concentration of 0.01g / mL 2 Methanol solution, stirring at 25°C for 8h, filtering, washing the filter cake with methanol, drying the filter cake under vacuum at room temperature, reducing it under hydrogen for 6h at 180°C, adding 4mL of methanol to the reduced catalyst, and then adding 0.1g of orthosilicate Ethyl ester, stirred at 25°C for another 16h, filtered, washed the filter cake with methanol, and vacuum-dried at 50°C for 12h to obtain the final catalyst C3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com