Nickel-doped zinc oxide hierarchical structure photocatalytic nano-material and preparation method thereof

A technology of hierarchical structure and nanomaterials, applied in the field of photocatalytic nanomaterials and environmental protection, can solve the problem of unsystematic research on the influence of photocatalytic activity, achieve excellent photocatalytic activity, improve visible light absorption, and improve quantum conversion efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

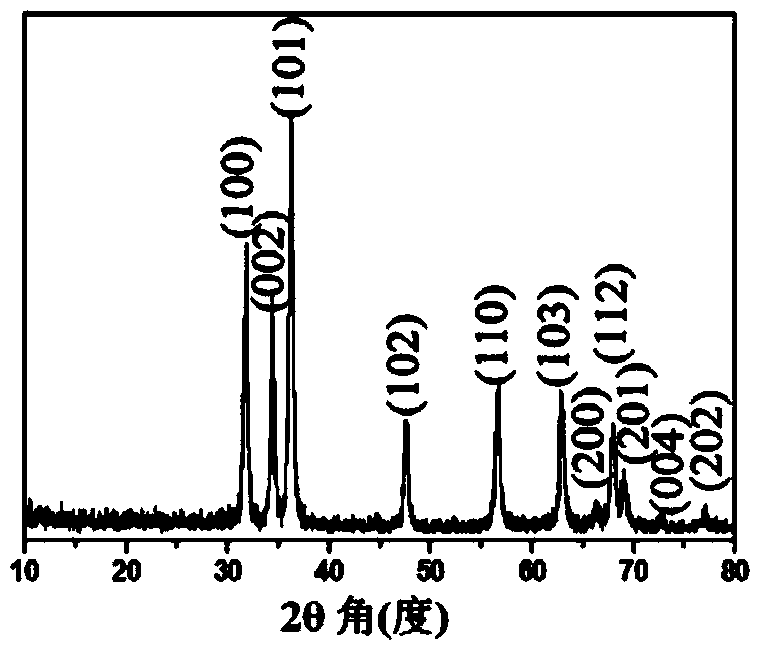

[0037] Example 1: Ni-doped zinc oxide hierarchical structure photocatalytic nanomaterials with visible light catalytic activity

[0038] The composition of the material is: Zn 1-x Ni x O, where x=0.5–10mol%. The appearance of the nickel-doped zinc oxide varies with Ni 2+ The difference in doping amount is shown as white and light green respectively.

[0039] The material has a particle size of 80–300nm and a specific surface area of 3.0–23.0m 2 / g; The shape is hollow spherical, hexagonal prism with sharp corners at both ends, spherical or icosahedral structure.

Embodiment 2

[0040] Example 2: Preparation method of nickel-doped zinc oxide hierarchical structure photocatalytic nanomaterial with visible light catalytic activity

[0041] The material is synthesized using the following reaction formula:

[0042] (1-x)Zn 2+ +xNi 2+ +2OH - →Zn 1-x Ni x (OH) 2 (1)

[0043] Zn 1-x Ni x (OH) 2 →Zn 1-x Ni x O+H 2 O (2)

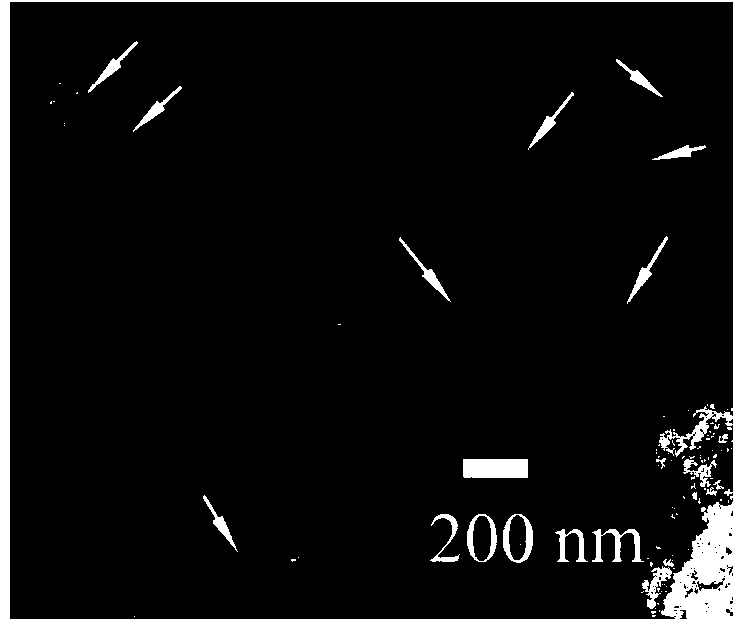

[0044] The material is obtained by the following method: 1.125×10 -3 mol zinc nitrate, 1.25×10 -4 mol nickel nitrate and 1.25×10 -3 mol sodium hydroxide was dissolved in 20mL methanol and stirred to obtain a precursor solution; the precursor solution was placed in a 50mL high-pressure reactor, sealed, and reacted at 200°C for 8h; after the reaction was completed, it was cooled to room temperature, and the product was washed repeatedly with ethanol, Dry at ℃ for 2 hours to prepare a 10mol% nickel-doped zinc oxide hollow spherical material with visible light catalytic degradation of dye wastewater. The microstructure of t...

Embodiment 3

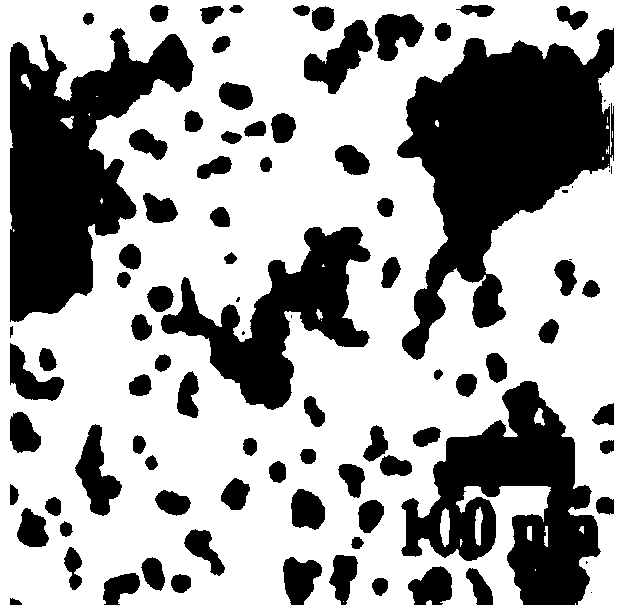

[0047] Using the process in Example 2, when the reaction time is 1.5 h, nickel-doped zinc oxide nanomaterials can also be obtained. The morphology of the obtained product is as image 3 As shown, it is a nanoparticle structure, and there is local self-aggregation into a microsphere structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com