Method for purification of quantum dot-streptavidin conjugate

A streptavidin and quantum dot technology, applied in chemical instruments and methods, peptide preparation methods, organic chemistry, etc., can solve problems such as difficulty in large-scale production, harsh operating conditions, and complex processes, and meet equipment requirements. Low, efficient separation, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1 water-soluble quantum dot streptavidin conjugate and purification process

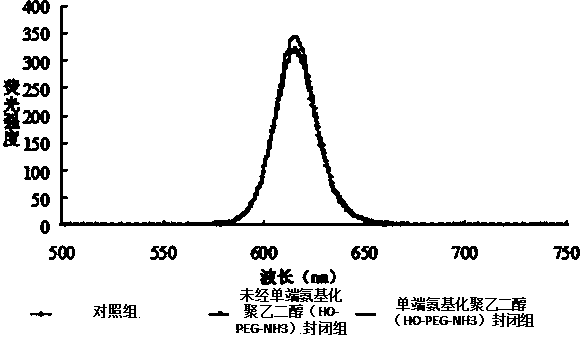

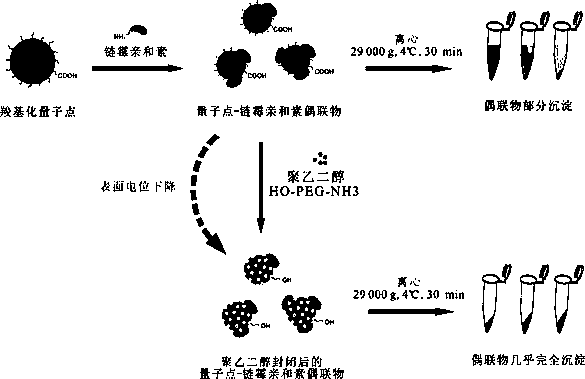

[0033] Take 5 mL of carboxylated water-soluble quantum dots (concentration: 50 nmol / L) and mix with an equal volume of 0.05 mol / L borate buffer at pH 5.0; add 1-ethyl -(3-Dimethylaminopropyl) carbodiimide and N-hydroxysulfosuccinimide, react at 37°C for 2 hours; add streptavidin solution with a molar ratio of 5:1 to quantum dots , adjust the pH of the solution to 8.0 with 1 M NaOH solution, react at room temperature for 3 hours; finally add polyethylene glycol with a final concentration of 1.5% to the solution, and further adjust the pH to 4.5 with 1 M HCl solution. 18,000 rpm (approx. 29,000 g) at 4°C for 30 min, discard the supernatant, and precipitate with 25% glycerol, 0.01% NaN 3 The water-soluble quantum dot streptavidin conjugate without free streptavidin was obtained by dissolving in 0.05 mol / L phosphate buffer (pH 7.0-7.5). After the water-soluble quantum dot streptavidin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com