Metal-oxide gas sensor based on MEMS (Micro-Electro-Mechanic System) and preparation technology thereof

A gas sensor and preparation process technology, applied in metal material coating process, process for producing decorative surface effects, semiconductor/solid-state device components, etc., can solve nanostructure pick-up, transfer, regular arrangement, mechanical adhesion The problems of electrical connection and process compatibility are difficult to achieve the effect of reducing temperature field asymmetry, high performance, and simple synthesis method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

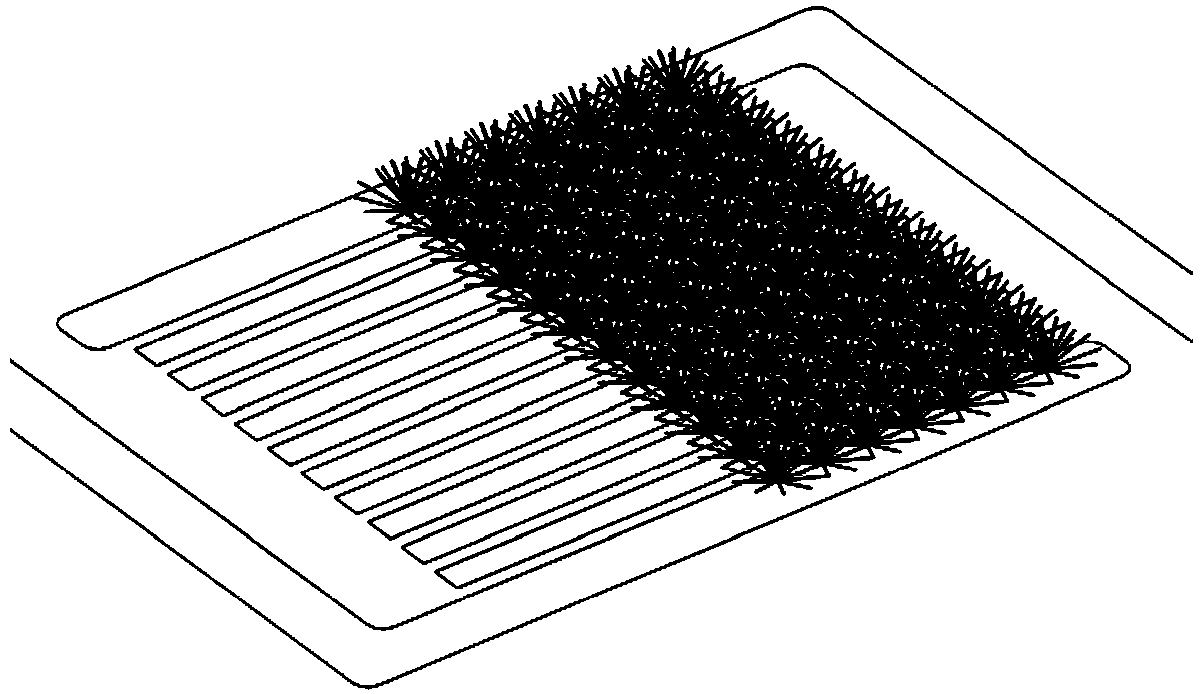

[0037] The metal oxide sensitive material of the gas sensor of the present invention is TiO 2 For example, but not limited to TiO 2 , can also be SnO 2 , ZnO, CuO. Different types of gas sensors can be produced by changing the type of metal oxide, or using multiple materials in combination.

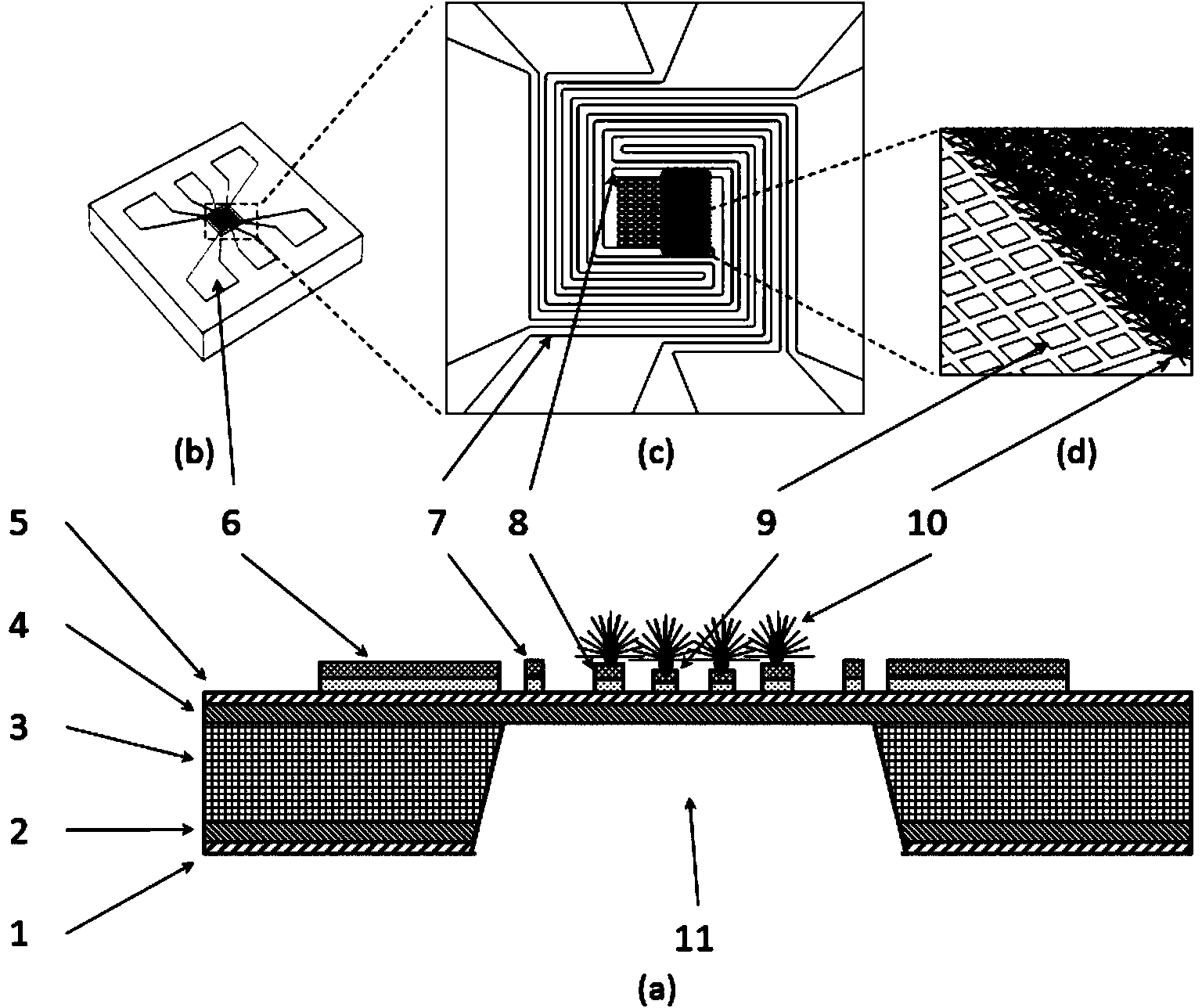

[0038] Such as figure 1As shown, a MEMS-based metal oxide nano-gas sensor, from bottom to top, respectively, wet-etched Si 3 N 4 Masking layer 1, SiO 2 Masking layer 2, Si substrate 3, SiO 2 Insulation layer 4, Si 3 N 4 An insulating layer 5, a heating element 7 made of a pair of Ti-Pt thin film resistors, a Ti-Pt sensitive electrode 8 and a Ti-Pt rectangular microarray 9, wherein a layer of TiO is grown on the rectangular microarray 9 2 3D Hierarchical Nanostructures10. Si in a certain area on the back of Si substrate 3 3 N 4 , SiO 2 The masking layer and Si are removed by wet etching to form an insulating groove 11[ figure 1 (a)].

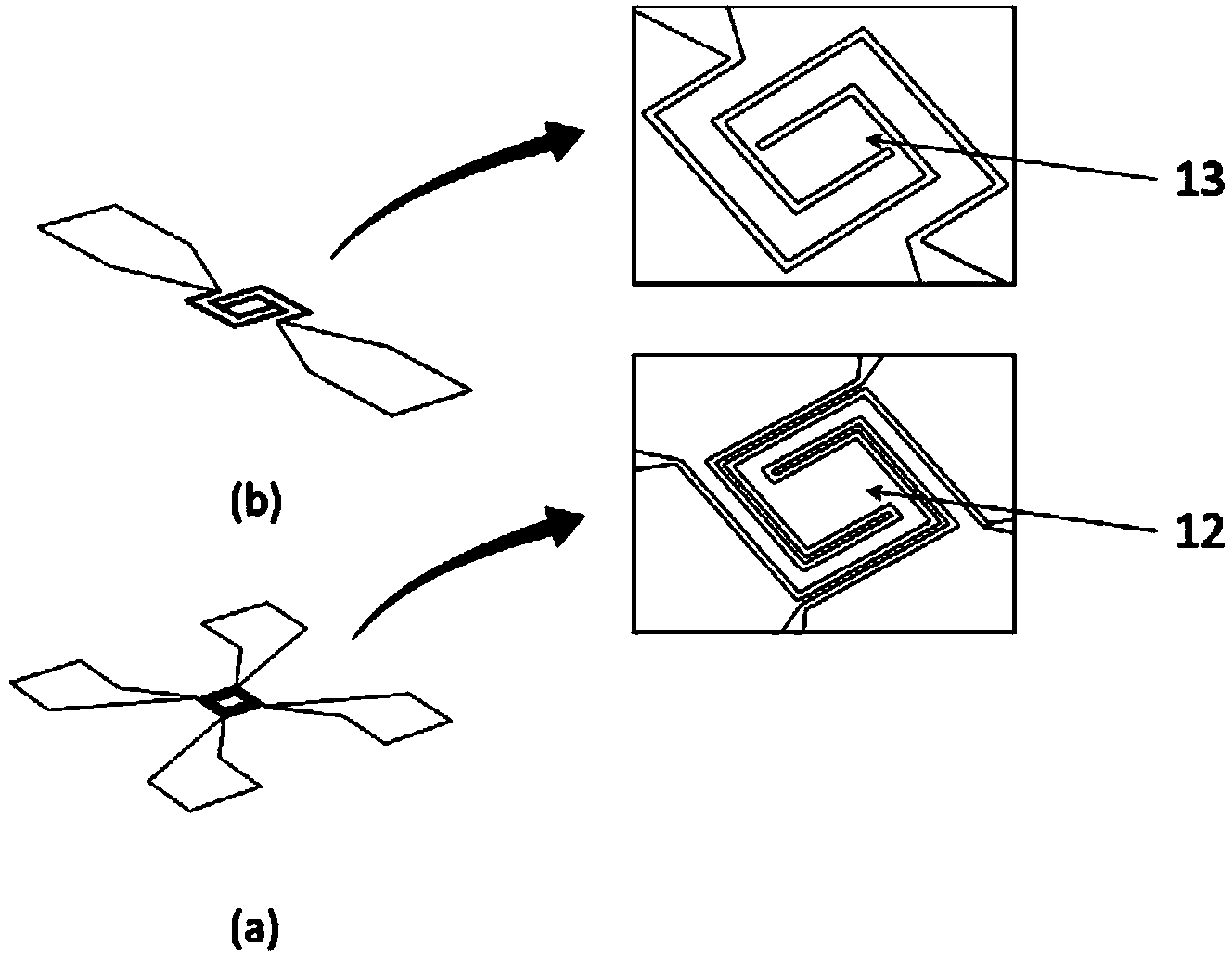

[0039] refer to figure 2 (a), a pair ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com