Ferrite magnet with salt and manufacturing method of the same

A technology of ferrite magnets and ferrite magnets, applied in the manufacture of inductors/transformers/magnets, magnetic objects, magnetic materials, etc., can solve problems such as deterioration of magnetic properties, inability to prevent particle growth, and increased process costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0126] Ba(NO 3 ) 2 and Fe(NO 3 ) 3 9H 2 O is used as a source material for barium ferrite. Mix Ba(NO 3 ) 2 and Fe(NO 3 ) 3 9H 2 A mixture of O is used as a source material for barium ferrite. Specifically, the Ba(NO 3 ) 2 and Fe(NO 3 ) 3 9H 2 O was added to deionized water and stirred for about 1 hour to prepare Ba(NO 3 ) 2 and Fe(NO at a molar concentration of 0.6M 3 ) 3 9H 2 Source material of barium ferrite composed of O.

[0127] Sodium chloride (NaCl) was added to the source material of barium ferrite to prepare a starting material. Sodium chloride was weighed and added so that the weight ratio with respect to the ferrite magnetic powder containing salt was 19% (19 weight% with respect to 100 weight% of the ferrite magnetic powder containing salt).

[0128] The starting material is sprayed to form droplets and allowed to mix with a carrier gas (O 2 ) together through the heated reaction chamber, thereby synthesizing barium ferrite magnetic powder wit...

Embodiment 2

[0134] A starting material was prepared using a source material of barium ferrite and sodium chloride in a similar manner to Example 1, but at a weight ratio of 31% relative to ferrite magnetic powder with salt (relative to 100% by weight of Sodium chloride was weighed and added so that ferrite magnetic powder with salt was 31% by weight).

[0135] In a similar manner to Example 1, the starting material was sprayed to form droplets and allowed to mix with the carrier gas (O 2 ) together through the heated reaction chamber, thereby synthesizing barium ferrite magnetic powder with salt.

Embodiment 3

[0137] The starting material was prepared using the source material of barium ferrite and sodium chloride in a similar manner to Example 1, but at a weight ratio of 53% (relative to 100% by weight) of ferrite magnetic powder with salt. Sodium chloride was weighed and added so that ferrite magnetic powder with salt was 53% by weight).

[0138] In a similar manner to Example 1, the starting material was sprayed to form droplets and allowed to mix with the carrier gas (O 2 ) together through the heated reaction chamber, thereby synthesizing barium ferrite magnetic powder with salt.

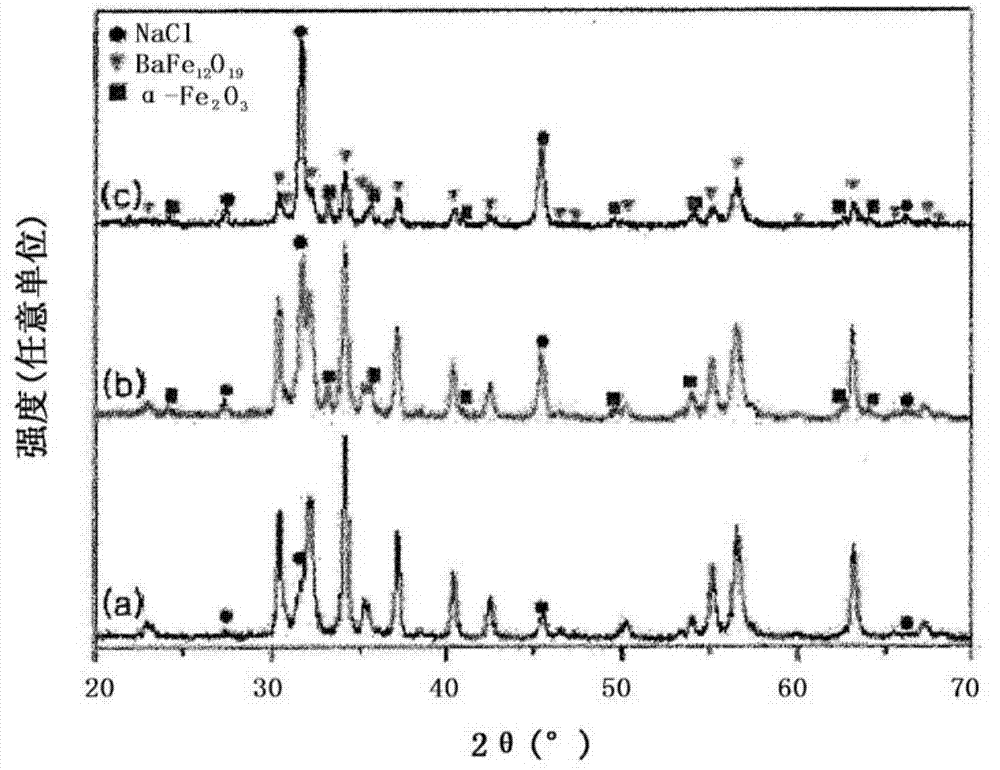

[0139] image 3 It is a graph showing the X-ray diffraction (XRD) pattern of the barium ferrite magnetic powder with sodium chloride synthesized according to Examples 1 to 3. image 3 a shows the X-ray diffraction (XRD) pattern of the barium ferrite magnetic powder with sodium chloride synthesized according to Example 1, image 3 b shows the X-ray diffraction (XRD) pattern of the barium ferrite ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com