High-radiation solar cell backboard

A solar cell, high heat dissipation technology, applied in the field of solar cells, can solve the problems of the battery components being easily corroded by water vapor, unable to dissipate heat, and the temperature of the battery components rising, so as to reduce the water vapor transmission rate, improve the water vapor barrier property, Improve the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In conjunction with the following diagrams, the embodiments of the present invention are described in detail

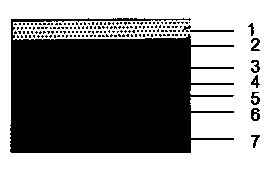

[0021] Such as figure 1 As shown, the present invention, that is, a high heat dissipation solar battery backsheet, includes a scratch-resistant and wear-resistant coating 1, a first adhesive layer 2, an aluminum alloy layer 3, a second adhesive layer 4, and an insulating barrier layer 5 connected in sequence. , a third adhesive layer 6 and an ethylene-vinyl acetate (EVA) adhesive layer 7 .

[0022] The anti-scratch and wear-resistant coating is a fluororesin coating modified by a highly dispersed nanoporous gas-phase SiO2 material, wherein the modified fluororesin can include polyvinylfluoride (PVF), polyvinylidene fluoride (PVDF), Polychlorotrifluoroethylene (Polychlorotrifluoroethylene, PCTFE), polytetrafluoroethylene (polytetrafluoroethylene, PTFE) or copolymer of tetrafluoroethylene and ethylene (ETFE). It is composed of two or more of them, processed in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com