Compound polyethylene glycol electrolyte composition

A polyethylene glycol and composition technology, applied in the field of medicine, can solve problems such as uncontrollable quality, uncontrolled quality, and loss of drug components, and achieve the goals of improving governance and drug efficacy, accelerating dissolution speed, and improving dispersibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the object, technical solution and advantages of the present invention clearer, preferred embodiments of the present invention are described in detail below.

[0031] The main instruments used in the preferred embodiment are as follows: hot air circulation oven (CT-C-II type Changzhou Yutong Equipment Co., Ltd.); air-cooled pulverizer (FL-350 Jiangsu Baobao Group Company); Baobao Group); Automatic Hopper Mixer (HZD800 Zhejiang Canaan Pharmaceutical Equipment Co., Ltd.).

[0032] 1. Determination of process route and parameters

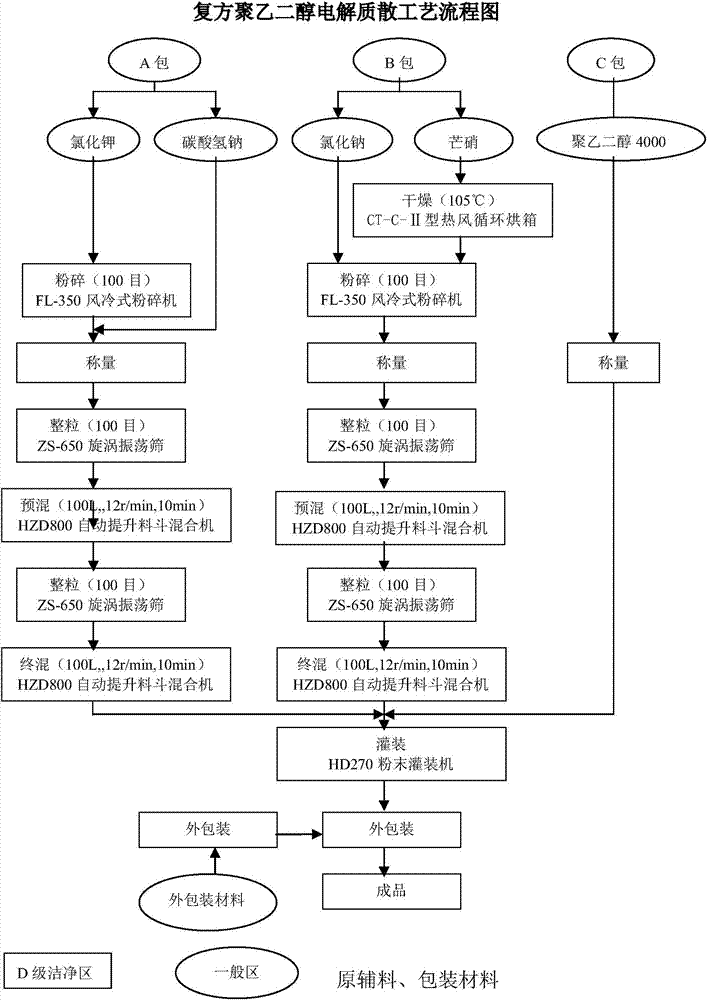

[0033] 1. Determination of the process route

[0034] The dosage form of this product is powder, and the preparation process is relatively simple. It does not need to add any auxiliary materials. It only needs to crush the raw materials of A, B, and C respectively, mix them well, and pack them separately.

[0035] There are many raw materials of this product, including potassium chloride, sodium bicarbonate, sodium chloride, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com