Carbon-based solid acid catalyst and preparation method thereof

A carbon-based solid acid and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc., can solve high cost, long solvothermal reaction time, solid The preparation method of acid catalyst is complex and other problems, to achieve the effect of easy recovery, good stability and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

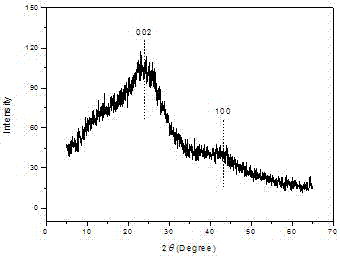

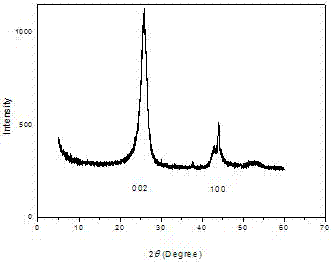

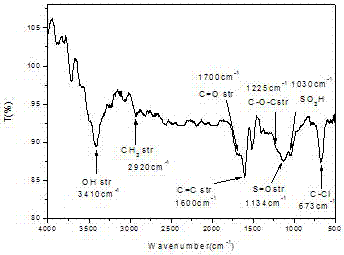

Method used

Image

Examples

Embodiment 1

[0030] Accurately weigh 8 g of medium-temperature asphalt and 2 g of chlorosulfonated polyethylene, mix them uniformly, put them into a tube furnace, and carbonize at 500°C for 12 h under the protection of nitrogen to obtain a black solid product, which is ground and passed through 200 meshes after cooling. screen.

[0031] The obtained carbonized product was sulfonated with sulfur trioxide at 100°C for 6 h, cooled to room temperature under nitrogen protection, filtered and washed with boiling water until no Cl was detected in the eluate. - , SO 4 2- , and dry at a certain temperature to obtain a carbon-based solid acid catalyst.

[0032] The density of sulfonic acid groups detected by analysis is 4.22mmol / g, and the chlorine content is 2.23mg / g. In a reactor with a condensing reflux device, put an appropriate amount of carbon-based solid acid catalyst, add absolute ethanol and glacial acetic acid (volume ratio is about 10:1), and react in a heating device with a constant-s...

Embodiment 2

[0035] Accurately weigh 5 g of cellulose and 5 g of PVC, mix them uniformly, put them into a quartz tube, place them in a vertical tube furnace, and carbonize them at 450 °C for 8 h under the protection of nitrogen to obtain a black solid product. Pass through a 200-mesh sieve after grinding. The resulting carbonized product and oleum were sulfonated at 150°C for 6 h under the condition of a mass volume ratio of 1 g: 20 ml under nitrogen protection. After cooling to room temperature, they were filtered and washed with boiling water until no trace was detected in the eluate. Out Cl - , SO 4 2- , and dry at a certain temperature to obtain a carbon-based solid acid catalyst. The density of sulfonic acid groups detected by analysis is 1.615mmol / g, and the chlorine content is 4.81mg / g. After accurately weighing 0.2 g of catalyst and 0.1 g of conventionally pretreated cellulose, 10 ml of distilled water was added and hydrolyzed at 150 °C for 6 h. The yield of reducing sugar in t...

Embodiment 3

[0038] Accurately weigh 6 g of lignin and 4 g of chlorinated polyvinyl chloride, mix them evenly, put them into a quartz tube, place them in a vertical tube furnace, and carbonize them at 400 °C for 8 h under the protection of nitrogen to obtain a black solid product , After cooling, it is ground and passed through a 200-mesh sieve. Sulfonate the obtained carbonized product and fuming concentrated sulfuric acid at 140°C under nitrogen protection for 5h at a mass volume ratio of 1 g: 20 ml. After cooling to room temperature, filter and wash with boiling water until no trace is detected in the eluate. Out Cl - , SO 4 2- , and dry at a certain temperature to obtain a carbon-based solid acid catalyst. The density of sulfonic acid groups detected by analysis is 1.215mmol / g, and the chlorine content is 5.78mg / g. After accurately weighing 0.2 g of catalyst and 0.1 g of cellulose and mixing them, 10 ml of distilled water was added and hydrolyzed at 160 °C for 5 h. The yield of red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com