Method for treating tertiary oil recovery wastewater by combining efficient dominant bacteria and flocculent precipitate

A technology of oil production wastewater and dominant bacteria, which is applied in flocculation/sedimentation water/sewage treatment, mining wastewater treatment, chemical instruments and methods, etc. It can solve problems such as low wastewater treatment rate, sludge system collapse, and difficulty in degrading emulsified oil. , to achieve the effect of high efficiency, low cost and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

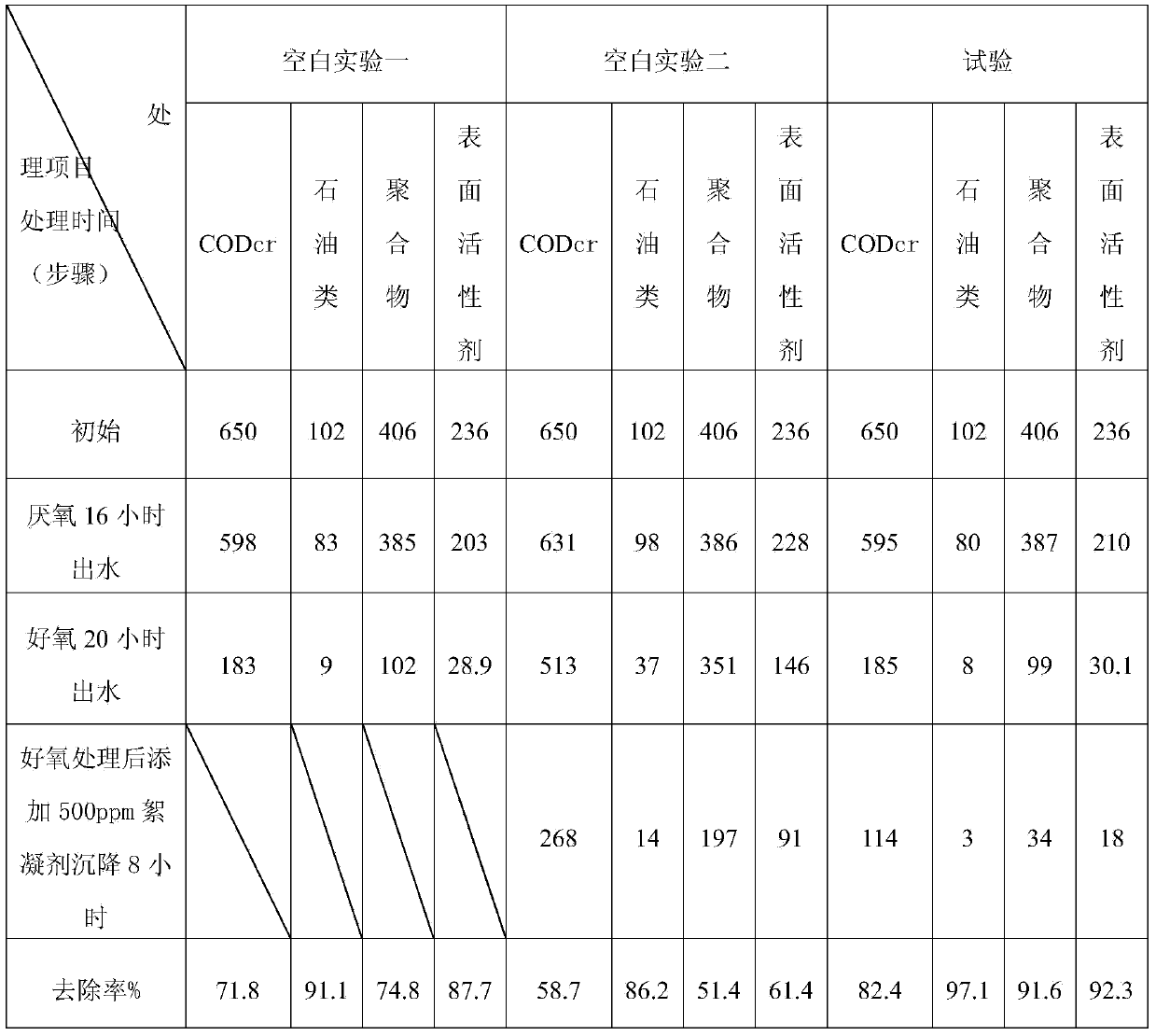

Embodiment 1

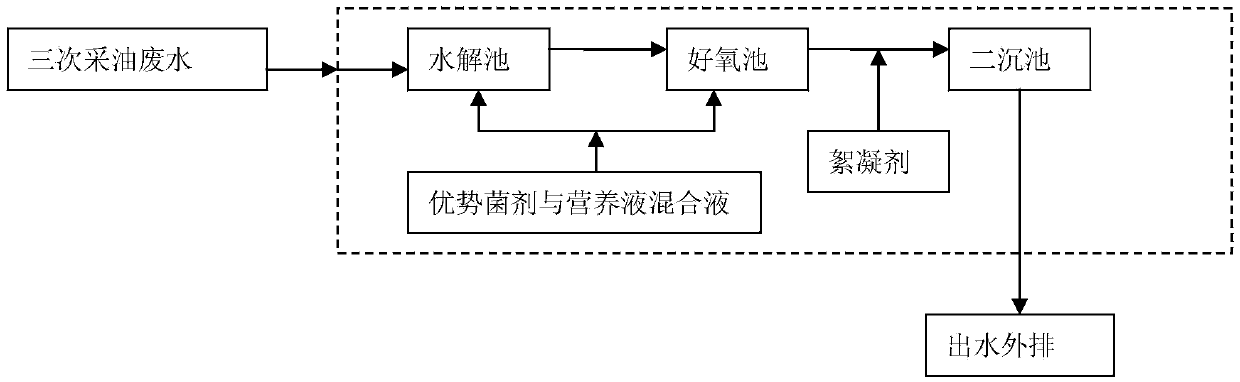

[0019] A method for treating tertiary oil recovery wastewater by utilizing high-efficiency dominant bacteria combined with flocculation and sedimentation, the steps of the method are:

[0020] ⑴. Select 1Kg of tertiary oil recovery wastewater from an oil production plant in Daqing Oilfield, and add 10% of the mixed solution for the first time, and a total of 100g of mixed solution is required. Among them, in the mixed solution, the mixing weight ratio is compound bacterial solution: nutrient solution = 1:9, then 10g of compound bacterial solution and 90g of nutrient solution are required.

[0021] ⑵, Bacillus albicans NKCCMR NK.DG-1, Bacillus pumilus NKCCMR NK2.10-1, Bacillus subtilis AS1.107, Pseudomonas oleander AS1.1641, Brevibacterium halotolerant NKCCMR NK2.B-3 five The microbial liquid is mixed evenly in the weight ratio of 1:2:2:2:3 to form a compound bacterial liquid. Calculated on the basis of 10g of the compound bacterial liquid, Bacillus albicans NKCCMR NK.DG-11g, B...

Embodiment 2

[0028] A method for treating tertiary oil recovery wastewater by utilizing high-efficiency dominant bacteria combined with flocculation and sedimentation, the steps of the method are:

[0029] ⑴. The effective volume is 1m 3 The treatment device is the tertiary oil recovery wastewater of an oil production plant in Daqing Oilfield. The ratio of the first mixed solution to be added is 10%, and a total of 100Kg of mixed solution is required. Among them, in the mixed solution, the mixing weight ratio is compound bacterial solution: nutrient solution = 1:9, then 10Kg of compound bacterial solution and 90Kg of nutrient solution are required.

[0030] ⑵. According to the water quality of this wastewater, Bacillus albicans NKCCMR NK.DG-1, Bacillus pumilus NKCCMR NK2.10-1, Bacillus subtilis AS1.107, Pseudomonas oleander AS1.1641, Brevibacterium halotolerant NKCCMR NK2.B-3 five kinds of microbial bacterial liquids are mixed evenly in a weight ratio of 2:3:1:2:2 to form a compound bacte...

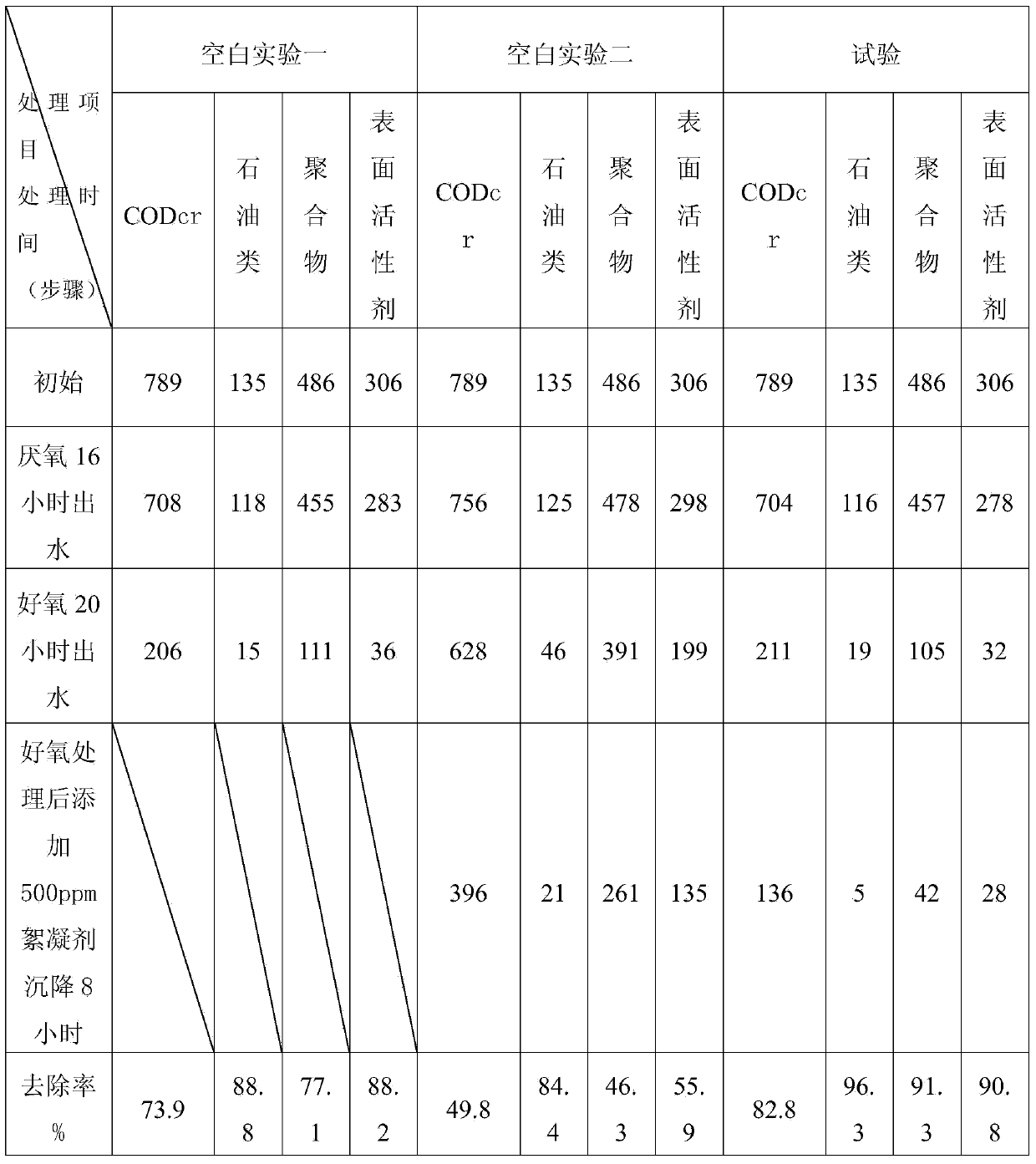

Embodiment 3

[0037] The field test of treating tertiary oil recovery wastewater by using high-efficiency dominant bacteria combined with flocculation and sedimentation has a sewage treatment scale of 3,000 tons / day: the specific implementation steps are as follows:

[0038]⑴. Using the field experiment of the tertiary oil recovery wastewater treatment station of an oil production plant in Daqing, the effective volume of the sewage treatment structure of the sewage treatment station is 4500m3, and the mixed solution dosage ratio is 3% of the effective volume, and a total of 135 tons of mixed solution is required. Among them, in the mixed solution, the mixing weight ratio is compound bacterial solution: nutrient solution = 1:4, then 27 tons of compound bacterial solution and 108 tons of nutrient solution are required.

[0039] (2) According to the wastewater quality on site, Bacillus albicans NKCCMR NK.DG-1, Bacillus pumilus NKCCMR NK2.10-1, Bacillus subtilis AS1.107, Pseudomonas oleander AS1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com