Cement paste stabilizer and preparation method thereof

The technology of stabilizer and cement slurry is applied in the field of cement slurry stabilizer for oilfield well cementing and its preparation, and achieves the effects of ensuring cementing quality, simple and easy method, and preventing free liquid and settlement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

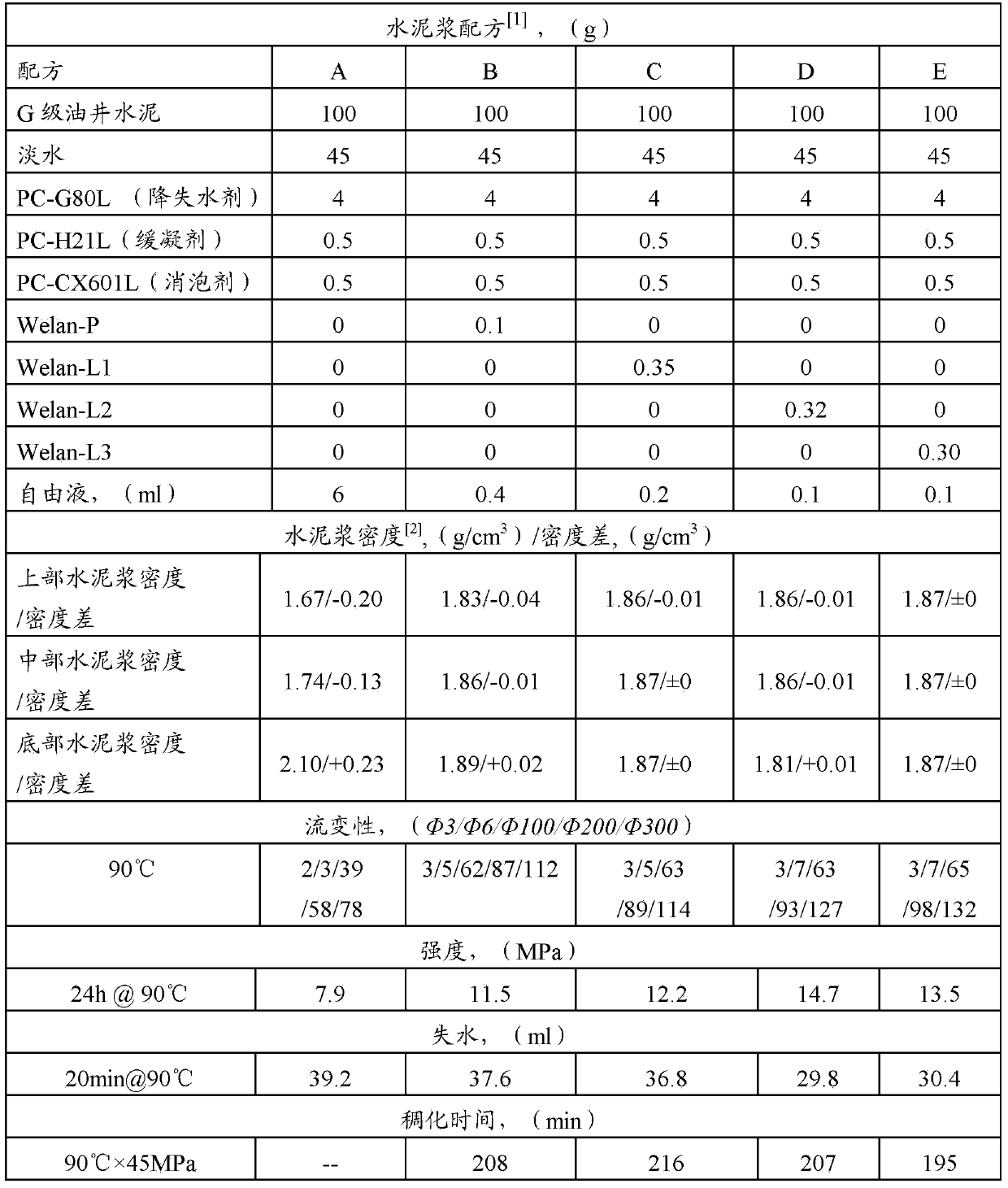

Examples

Embodiment 1

[0035] Weigh 400g of No.5 white oil (Sinopec Maoming Branch) and put it in the slurry cup, and put the slurry cup on the variable speed stirrer, slowly add 24.0g of organic soil PF-MOLGEL treated with bentonite and quaternary ammonium salt at 120rpm (Tianjin Zhonghai Oil Service Chemical Co., Ltd.), and after stirring at this speed for 20 minutes, after the white oil was thickened, add 4.0g Span85 (Jiangsu Haian Petrochemical Factory, product brand S-85, its HLB value is 1.8) and 12.0 g Teen80 (Jiangsu Hai'an Petrochemical Factory, product brand T-80, its HLB value is 15) composed of fluid state regulator, 120rpm stirring evenly after adding 140g powdery Wenlun gum (Hebei Juxin Biochemical Co., Ltd., product Model BG3810), after stirring at a low speed of 50 rpm for 50 minutes, the cement slurry stabilizer Welan-L1 can be obtained, wherein the mass concentration of welan glue is 24.1% by weight.

Embodiment 2

[0037] Weigh 400g of No.5 white oil (Sinopec Maoming Branch) and put it in the slurry cup, and place the slurry cup on the variable speed stirrer, slowly add 20.0g of organic soil PF-MOLGEL treated with bentonite and quaternary ammonium salt at 120rpm (Tianjin Zhonghai Oilfield Chemical Co., Ltd.), and after stirring at this speed for 20 minutes, after the white oil is thickened, add 3.5g Span85 (Jiangsu Haian Petrochemical Factory, the product grade S-85 has an HLB value of 1.8) and 15.0g Teen60 (Jiangsu Haian Petrochemical Plant, product brand T-60, its HLB value is 14.5) is a flow conditioner, after stirring at 120rpm, add 160g powdered Wenlun gum (Hebei Juxin Biochemical Co., Ltd., product model BG3810), after stirring at a low speed of 50 rpm for 50 minutes, the cement slurry stabilizer Welan-L2 can be obtained, wherein the mass concentration of welan gum is 26.7%.

Embodiment 3

[0039] Weigh 400g of No.5 white oil (Sinopec Maoming Branch) and place it in a slurry cup, and place the slurry cup on a variable speed agitator, and slowly add 15.0g of organic soil PF-MOLGEL treated with bentonite and quaternary ammonium salt at 120rpm (Tianjin Zhonghai Oilfield Chemical Co., Ltd.), and after stirring at this speed for 20 minutes, after the white oil was thickened, add 5.0g Span85 (Jiangsu Haian Petrochemical Factory, product grade S-85, its HLB value is 1.8) and 9.5 g Teen20 (Jiangsu Haian Petrochemical Factory, product grade T20, its HLB value is 16.5) is a flow conditioner, after stirring at 120rpm, add 180g powdered Wenlun gum (Hebei Juxin Biochemical Co., Ltd., product model BG3810 ), after stirring at a low speed of 50 rpm for 50 minutes, the cement slurry stabilizer Welan-L3 can be obtained, wherein the mass concentration of welan glue is 29.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com