Lithium ion selenium battery with long service life

A lithium-ion battery and electrolyte technology, applied in the field of electrochemical power supply, can solve problems such as corrosion, battery short circuit, and potential safety hazards, and achieve the effects of good safety, long life and high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

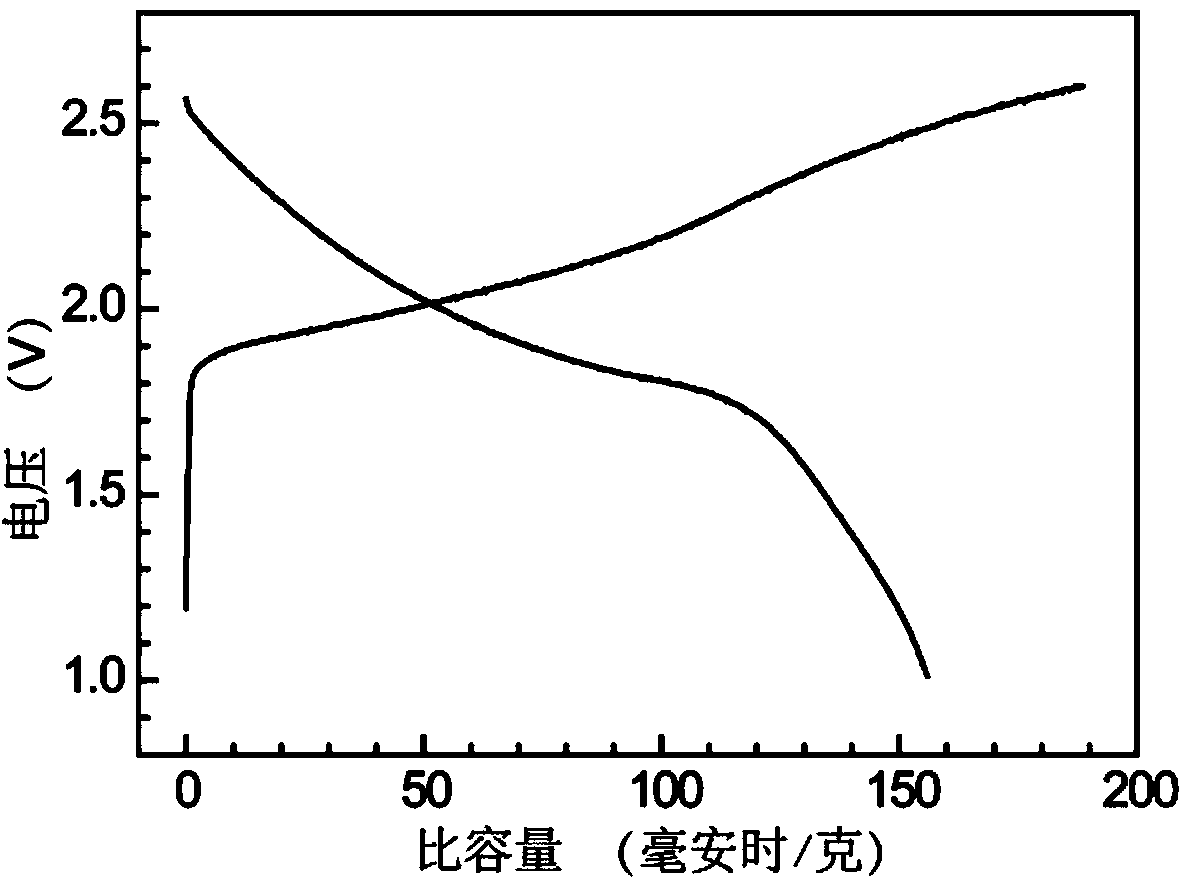

[0023] Example 1. Assembly of ternary positive electrode / selenium micro-mesoporous carbon composite negative electrode full battery and its electrochemical performance test

[0024] 1-1 Preparation of positive electrode

[0025] According to the ternary cathode material (LiCo 1 / 3 Ni 1 / 3 mn 1 / 3 o 2 ): carbon black: polyvinylidene fluoride = 8:1:1 ratio (mass ratio) mixed, mixed evenly, coated on the current collector, vacuum dried, sliced to obtain a ternary positive electrode.

[0026] 1-2 Preparation of negative electrode

[0027] Mix according to the ratio (mass ratio) of selenium micro-mesoporous carbon composite: Ketjen black: sodium carboxymethyl cellulose / styrene-butadiene rubber = 8:1:1, after mixing evenly, coat it on the current collector, and vacuum After drying and slicing, the selenium micro-mesoporous carbon negative electrode is obtained.

[0028] 1-3 full battery assembly

[0029] Insert a glass fiber membrane (Whatman, UK) between the positive and negati...

Embodiment 2

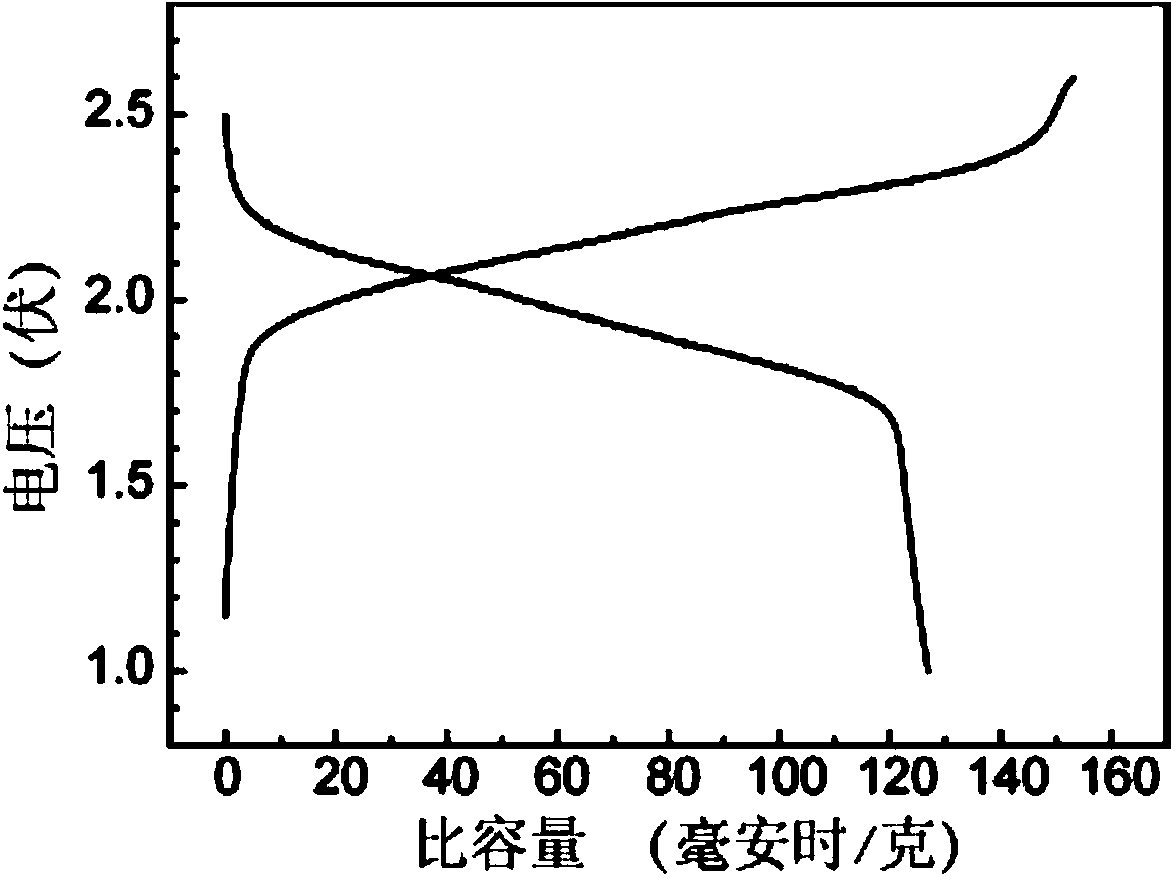

[0040] Example 2. Assembly of ternary positive electrode / selenium-porous titanium dioxide composite negative electrode full battery and its electrochemical performance test

[0041] 2-1 Preparation of positive electrode

[0042] According to the ternary cathode material (LiCo 0.2 Ni 0.4 mn 0.4 o 2 ): carbon black: polytetrafluoroethylene = 8:1:1 ratio (mass ratio) mixed, mixed evenly, coated on the current collector, dried in vacuum and sliced to obtain a ternary positive electrode.

[0043] 2-2 Preparation of negative electrode

[0044] According to the ratio (mass ratio) of selenium-porous titanium dioxide composite: Ketjen black: cyclodextrin = 8:1:1 (mass ratio), mix evenly, coat on the current collector, vacuum dry and slice to obtain selenium- Porous titanium dioxide composite negative electrode.

[0045] Assembly of 2-3 full cells

[0046] Insert a glass fiber membrane (Whatman, UK) between the positive and negative electrodes as a separator, add carbonate elec...

Embodiment 3

[0049] Example 3. Assembly of ternary positive electrode / selenium-polythiophene composite negative electrode full battery and its electrochemical performance test

[0050] 3-1 Preparation of positive electrode

[0051] According to the ternary cathode material (LiCo 0.2 Ni 0.5 mn 0.3 o 2 ): carbon black: polyvinylpyrrolidone = 8:1:1 ratio (mass ratio) mixed, mixed evenly, coated on the current collector, dried in vacuum and sliced to obtain a ternary positive electrode.

[0052] 3-2 Preparation of negative electrode

[0053] Mix according to the ratio (mass ratio) of selenium-polythiophene composite: carbon black: gelatin = 8:1:1, mix evenly, coat on the current collector, vacuum dry and slice to obtain selenium-polythiophene composite negative electrode.

[0054] 3-3 Assembly of full battery

[0055] A glass fiber membrane (Whatman, UK) was inserted between the positive and negative electrodes as a separator, and an ether electrolyte [1M LiTFSI TEG / DME (mass ratio 1:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com