Preparation method of atomized silver and zinc oxide electrical contact materials containing additives

An electric contact material, silver zinc oxide technology, applied in contacts, circuits, electric switches, etc., can solve the problem of not being able to add high-melting point additives, achieve low cost, improve additive segregation, and shorten the processing cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

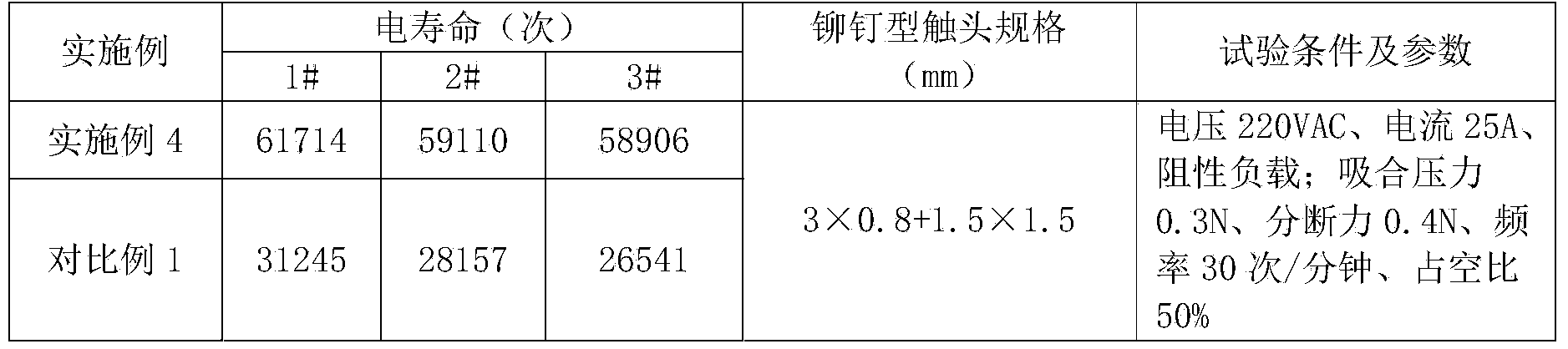

Examples

Embodiment 1

[0026] 1) According to the preparation of 10kg of Ag-8ZnO-5Er 2 o 3 Material proportioning calculates the consumption of each raw material, takes by weighing 10kg of pure silver block, 0.736kg of pure zinc block, 1.16kg of erbium nitrate, and sets aside;

[0027] 2) Take pure silver and pure zinc ingots and place them in an intermediate frequency melting furnace to melt into a uniform alloy melt, atomize them through high-pressure water atomization equipment, dry the obtained powder slurry, and pass through a 100-mesh sieve to obtain silver alloys. Zinc alloy powder;

[0028] 3) Take erbium nitrate and dissolve it with 3L of absolute ethanol to form an ethanol solution of erbium nitrate, add 9.34kg of silver-zinc alloy powder, and mix the obtained slurry with a low-speed mixer (the time is 2h, and the number of revolutions is 30r / min) , obtaining the silver-zinc alloy powder slurry with uniform distribution of erbium nitrate;

[0029] 4) Dry the silver-zinc alloy powder slu...

Embodiment 2

[0033] 1) According to the preparation of 10kg of Ag-10ZnO-1.5CuO-1Mo 2 o 3 -0.5La 2 o 3 Material ratio calculation of the amount of each raw material, weighing 10kg pure silver block, 0.92kg pure zinc block, copper nitrate 0.454kg, ammonium molybdate 0.136kg, lanthanum nitrate 0.133kg, spare;

[0034] 2) Put the pure silver block and pure zinc block in the intermediate frequency smelting furnace to melt into a uniform alloy melt, atomize it through high-pressure water atomization equipment, dry the obtained powder slurry, and pass through a 100-mesh sieve to obtain silver Zinc alloy powder;

[0035]3) get copper nitrate, lanthanum nitrate, ammonium molybdate and dissolve with 2L of water, be made into the aqueous solution of copper nitrate, ammonium molybdate and lanthanum nitrate, add 9.5kg silver-zinc alloy powder, the gained slurry carries out mixing process with low-speed mixer ( The time is 2h, and the number of revolutions is 30r / min), obtains the silver-zinc alloy ...

Embodiment 3

[0040] 1) According to the preparation of 10kg of Ag-12ZnO-2WO 3 -0.5Li 2 o 3 Material ratio Calculate the amount of each raw material, weigh 10kg of pure silver block, 1.12kg of pure zinc block, 0.209kg of ammonium metatungstate, 0.23kg of lithium nitrate, and set aside;

[0041] 2) Take pure silver and pure zinc ingots and place them in an intermediate frequency melting furnace to melt into a uniform alloy melt, atomize them through high-pressure water atomization equipment, dry the obtained powder slurry, and pass through a 200-mesh sieve to obtain silver alloys. Zinc alloy powder;

[0042] 3) Dissolve ammonium metatungstate and lithium nitrate in 3L of water to form an aqueous solution of ammonium metatungstate and lithium nitrate, add 9.51kg of silver-zinc alloy powder, and mix the obtained slurry with a low-speed mixer (1h, Number of revolutions is 30r / min), obtains the silver-zinc alloy powder slurry that ammonium metatungstate and lithium nitrate are evenly distribu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com