A kind of method and device of pulse energy-saving MBR

A pulse and control switch technology, applied in chemical instruments and methods, sustainable biological treatment, water/sludge/sewage treatment, etc., can solve the problems of easy membrane pollution, high energy consumption of aeration, high operating costs, etc., and achieve relief Effects of membrane fouling, reduction of EPS release, improvement of hydrodynamic performance and mass transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

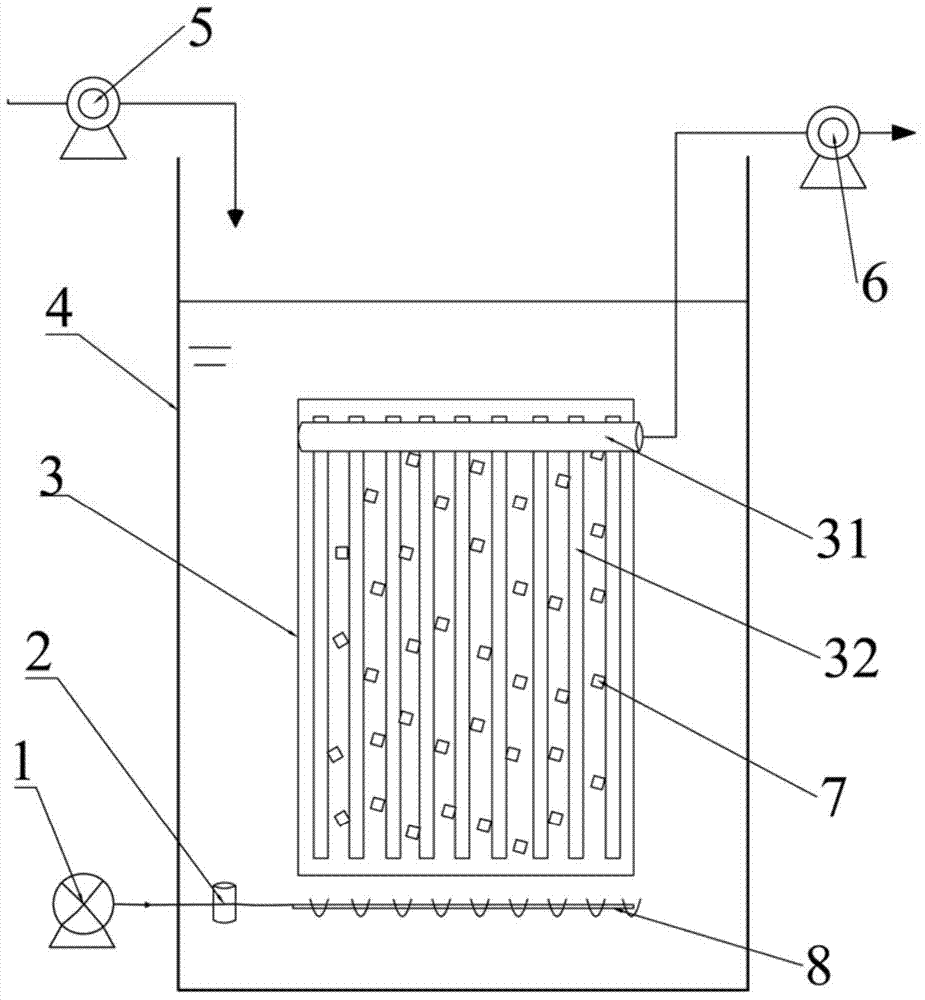

[0031] like figure 1 Described, a kind of pulse energy-saving MBR device, wherein, comprise membrane tank 4, membrane group device 3, aeration pipe 8 and aeration machine 1, the water inlet of membrane tank 4 is equipped with water inlet pump 5, and membrane group device 3 is set In the membrane tank 4, the membrane group device 3 includes several membrane elements 32 and water collection pipes 31, the membrane elements 32 are arranged in the membrane group device 3 at intervals, and each membrane element 32 is provided with a water outlet for collecting clean water , and the water outlet on each membrane element 32 is in communication with the water collection pipe 31, the outlet of the water collection pipe 31 is connected with the produced water pump 6, the aeration pipe 8 is located below the membrane stack 3, and the outlet of the aerator 1 is sequentially Connect with according to control switch 2 and aeration pipe 8. The control switch 2 can automatically control the p...

example 1

[0038] A domestic sewage treatment project with a treatment capacity of 1000m 3 / d, raw water COD Cr 200-500mg / L, ammonia nitrogen 40-50mg / L, SS100-230mg / L. The pulse energy-saving type MBR device of the present invention is used for processing, wherein the membrane element 32 used is a flat film; the filler 7 is a polyurethane filler, and the shape of the filler 7 is a honeycomb sponge.

[0039] COD of effluent after treatment Cr 20-50mg / L, ammonia nitrogen<3mg / L, SS<1mg / L. The cleaning cycle is increased from 120 days to 180 days, and the cleaning cost is reduced by 30%.

example 2

[0041] A waste water treatment and reuse project in an industrial park, with a treatment capacity of 500m 3 / d, raw water COD cr 300-800mg / L for ammonia nitrogen, 40-90mg / L for ammonia nitrogen, and 250-400mg / L for SS. The pulse energy-saving MBR device of the present invention is used for processing, wherein the membrane element 32 used is a hollow fiber membrane; the filler 7 is a combined filler; the shape of the filler 7 is a sheet. After treatment, effluent COD cr Less than 50mg / L, turbidity less than 1NTU. The system has been running for one month, and the transmembrane pressure (TMP) has risen from 2.1KPa to 6.3kPa. The membrane pressure difference has risen steadily and the operation is stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com