Advanced treatment method for synchronously removing phosphorus and COD (Chemical Oxygen Demand) of secondary biochemical treatment effluent

A secondary biochemical effluent and advanced treatment technology, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., to achieve low process transformation and operation costs, low operation costs, and simple processes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] water quality index pH Total phosphorus (mg / L) COD Cr (mg / L) TN (mg / L) Ammonia nitrogen (mg / L) Water sample to be treated 7.22 1.75 58 15.6 5.5

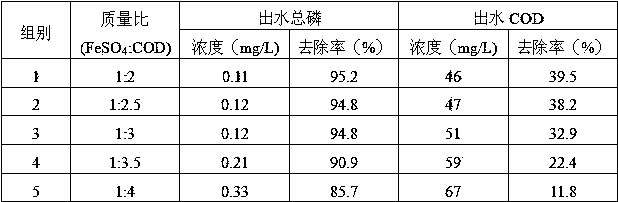

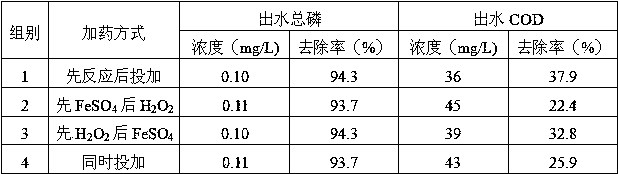

[0026] Take a certain amount of secondary biochemical effluent of the sewage plant and place it in the reactor, adjust the pH value to 4.5; the final dosage is 19.3mg FeSO 4 / L water sample and 4.32 mg H 2 o 2 / L water sample (ie FeSO 4 The mass ratio of the dosage to the COD content in the water sample to be treated is 1:3) Mix the two agents and react in the dark for 30 seconds; then add the agent after the mixed reaction to the water sample to be treated, and stir the reaction (at 300r / min Stir rapidly for 30 seconds, stir slowly at 80r / min for 15 minutes), settle for 120 minutes, and the supernatant is the effluent after treatment. It is detected that the total phosphorus in the water is 0.10 mg / L, and the removal rate is 94.3%; the COD is 36 mg / L, and the removal rate is 37.9%; it meet...

Embodiment 2

[0028] water quality index pH Total phosphorus (mg / L) COD Cr (mg / L) TN (mg / L) Ammonia nitrogen (mg / L) Water sample to be treated 7.41 2.31 76 16.2 6.4

[0029] Take a certain amount of secondary biochemical effluent of the sewage plant and place it in the reactor, adjust the pH value to 4.5; the final dosage is 30.4mg FeSO 4 / L water sample and 6.80 mg H 2 o 2 / L water sample (ie FeSO 4 The mass ratio of the dosage to the COD content in the water sample to be treated is 1:2.5) Mix the two agents and react in the dark for 30 seconds; then add the agent after the mixed reaction to the water sample to be treated, and stir the reaction (at 300r / min Stir rapidly for 30 seconds, stir slowly at 80r / min for 15 minutes), settle for 120 minutes, and the supernatant is the effluent after treatment. It was detected that the total phosphorus in the water was 0.12 mg / L, the removal rate was 94.8%, and the COD was 47mg / L, the removal rate was 38.2%, meeti...

Embodiment 3

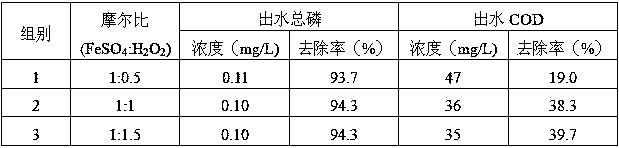

[0031] Taking secondary biochemical effluent in embodiment 1 as treatment object, determine FeSO 4 The final dosage is 19.3mg / L water sample, control H 2 o 2 The final dosage is 2.16 mg / L water sample, 4.32 mg / L water sample, 6.48 mg / L water sample respectively, namely FeSO 4 and H 2 o 2 The molar ratio of dosage is 1:0.5, 1:1, 1:1.5 respectively, and other carry out 3 groups of parallel synchronous dephosphorization and COD advanced treatment experiments according to the implementation mode in Example 1, and the results are as follows:

[0032]

[0033] It can be seen from the results that when FeSO 4 and H 2 o 2 When the dosing molar ratio is 1:1, good effects on total phosphorus and COD have been achieved, and the dosage of chemicals is more economical.

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com