Non-formaldehyde fluorescent paint emulsion and preparation method thereof

A technology of fluorescent paint and formaldehyde, which is applied in the field of textile printing auxiliaries to achieve excellent fluorescence and rheology, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following examples are further illustrations of the present invention, but the present invention is not limited thereto.

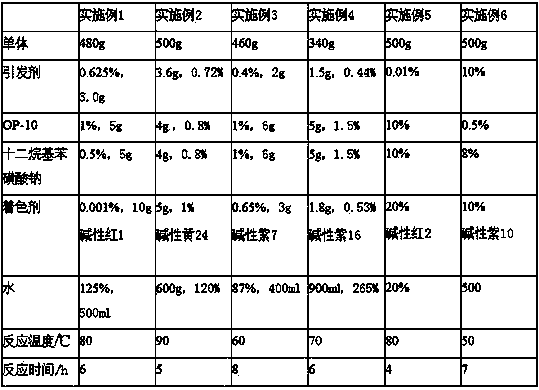

[0015] Embodiment 1-6 prepares the raw material of formaldehyde-free fluorescent paint emulsion as shown in Table 1, and monomer component is shown in Table 2:

[0016] Table 1

[0017]

[0018] Table 2

[0019] Example 1 2 3 4 Methyl acrylate 100g,20.8% 70g,14% 120g,26% 170g,50% Methyl methacrylate 200g,42% 150g,30% 230g,50% 60g,17.6% acrylic acid 30g,6.25% 10g,2% 0 15g,4.4% Methacrylate 0 20g,4% 30g,6.52% 15g,4.4% Styrene 150g,31.3% 250g,50% 80g,17.4% 80g,34% Total monomer weight g 480 500 460 340

[0020] The preparation process is as follows: Add the monomer mixture into a 2000ml four-neck flask, add azobisisobutyrocyanide while stirring, and then add the aqueous solution containing OP-10, sodium dodecylbenzenesulfonate and fluorescent dye, Stir quickly to emulsif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com