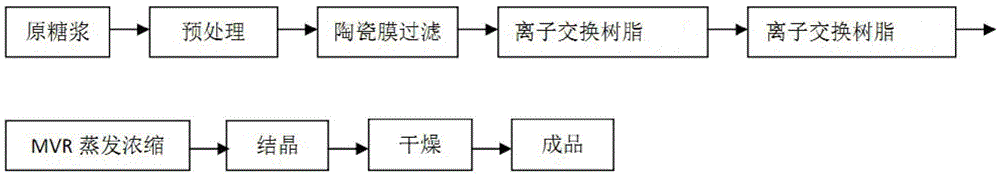

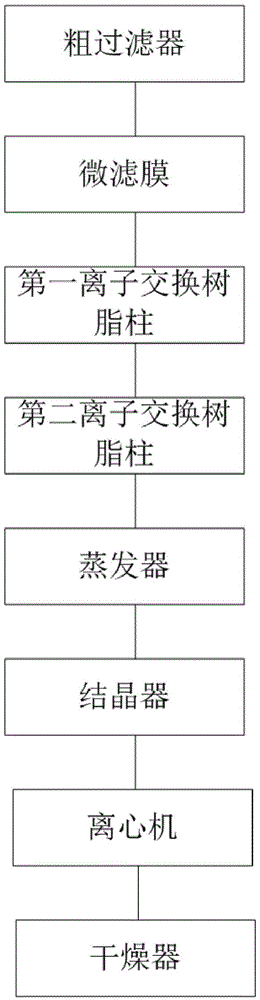

Process and device for two-step sugar production

A two-step method and process technology, applied in the production of sugar, sugar products, sucrose production, etc., can solve the problems of energy waste, low production efficiency, waste of energy, etc., and achieve significant economic benefits, save labor costs, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of novel technology of sucrose production, it comprises the following steps:

[0033]A. Sugar: Add water and heat to 80°C to dissolve the raw sugar to make syrup. The sucrose content is about 40%, 50%, 60%, 70%, and 80% respectively;

[0034] B. Pretreatment: The syrup is pretreated through the plate frame to remove colloid or larger granular impurities; the accuracy of the plate frame filter cloth used is 0.1 μm;

[0035] C. Ceramic membrane filtration: the collected pretreated syrup is micro-filtered through a ceramic membrane, the average pore size is 50nm, the filtration temperature is 50°C, and the filtration pressure is 0.5Mpa to obtain the syrup clear liquid;

[0036] D. Primary ion-exchange desalination: Use macroporous strong basic anion-exchange resin for ion-exchange desalination of the syrup clear liquid, which can also play a role in decolorization. The flow rate in the resin column is 2BV / h, and the temperature is 70°C. The diameter-to-height ratio...

Embodiment 2

[0045] A kind of novel technology of sucrose production, it comprises the following steps:

[0046] A. Melting sugar: add water and heat to 80°C to dissolve the raw sugar to make a syrup, and the sucrose content is about 60% respectively;

[0047] B. Pretreatment: The syrup is pretreated through the plate frame to remove colloid or larger granular impurities; the accuracy of the plate frame filter cloth used is 5 μm;

[0048] C. Ceramic membrane filtration: the collected pretreated syrup is microfiltered through a ceramic membrane, the average pore size is 50nm, 200nm and 500nm respectively, the temperature of filtration is 90°C, and the filtration pressure is 0.1Mpa to obtain the syrup clear liquid;

[0049] D. Primary ion-exchange desalination: Use macroporous strong basic anion-exchange resin for ion-exchange desalination and decolorization of the syrup clear liquid. The flow rate in the resin column is 10BV / h, the temperature is 40°C, and the diameter-to-height ratio is 1 / ...

Embodiment 3

[0058] A kind of novel technology of sucrose production, it comprises the following steps:

[0059] A. Melting sugar: add water and heat to 80°C to dissolve the raw sugar to make a syrup, and the sucrose content is about 60% respectively;

[0060] B. Pretreatment: The syrup is pretreated through the plate frame to remove colloid or larger granular impurities; the accuracy of the plate frame filter cloth used is 4 μm;

[0061] C. Ceramic membrane filtration: The collected pretreated syrup is micro-filtered through a ceramic membrane, the average pore size is 200nm, the filtration temperatures are 50°C, 70°C, and 90°C, and the filtration pressure is 0.4Mpa to obtain clear syrup. liquid;

[0062] D. One-stage ion exchange desalination: The syrup clear liquid is desalted and decolorized by ion exchange with macroporous strong basic anion exchange resin. The flow rate in the resin column is 4BV / h, the temperature is 60°C, and the diameter-to-height ratio is 1 / 8 , the Brix of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com