CIGS in-situ doping method

An in-situ doping and elemental technology, applied in the direction of sustainable manufacturing/processing, electrical components, climate sustainability, etc., can solve problems such as increasing production conditions and increasing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

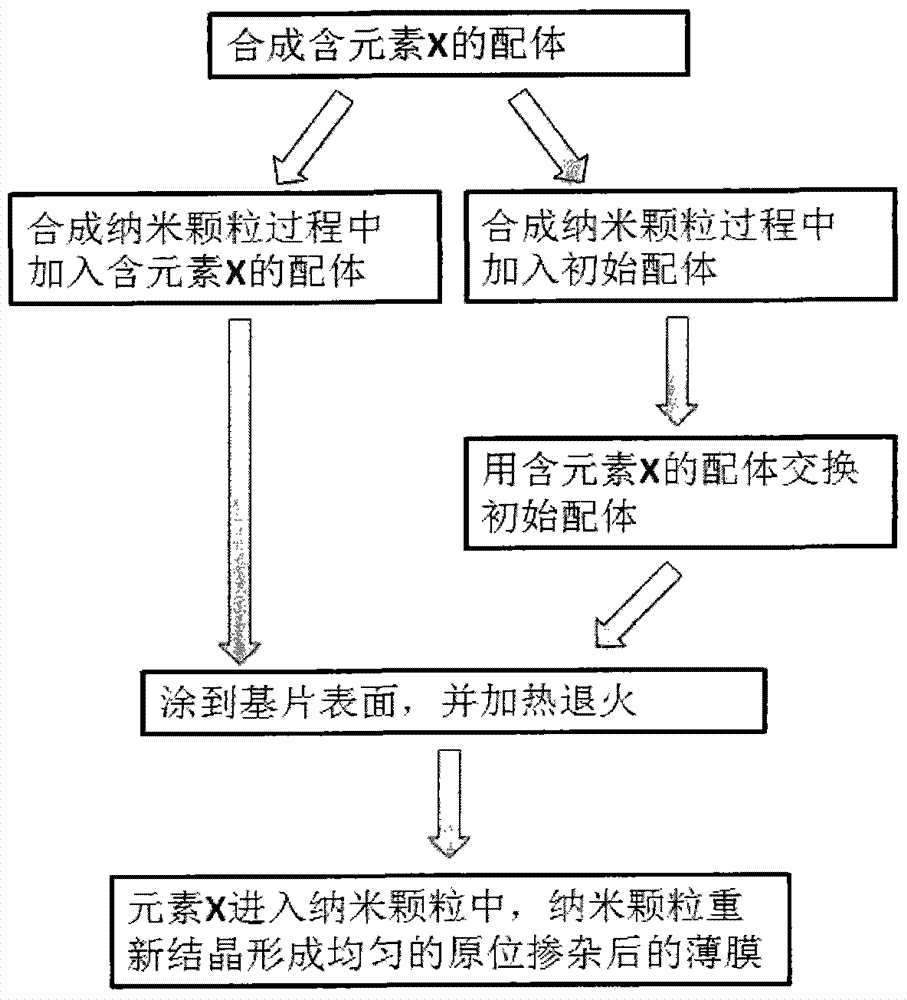

Method used

Image

Examples

Embodiment approach 1

[0011] Embodiment 1 In-situ doping of ligand exchange of S element (via Na 2 S)

[0012] Step 1: Synthesis of CIGS nanoparticles

[0013] There are many methods for synthesizing CIGS nanoparticles. This embodiment adopts one of them, but it is not only possible to implement this one. This type of implementation requires the introduction of two ligands. One ligand (referred to as the initial ligand) is used to synthesize CIGS nanoparticles, and the other ligand (referred to as the exchange ligand) is used to carry the required specific elements (Se, Na, S, Sn, Se , In, Sb, Ga, Te, Mo, As, etc.).

[0014] At room temperature, 104.8mg of copper acetylacetonate (Copper(II) acetylacetonate, referred to as Cu(acac) 2 ), 73.4mg of gallium acetylacetonate (Gallium(IlI) acetylacetonate for short Ga(acac) 3 ) And 82.4mg of Indium(III)acetylacetonate In(acac) 3 ) Mix, and add 10 mL of Oleylamine (Oleylamine, OLA for short, is an initial ligand). Then put the prepared solution in a vacuum env...

Embodiment approach 2

[0024] Embodiment 2 In-situ doping of ligand exchange of S element ((NH 4 ) 2 S)

[0025] Step 1: Synthesis of CIGS nanoparticles

[0026] Same as the method described in step 1 in embodiment 1.

[0027] Step two exchange ligands

[0028] Add 20g of aqueous ammonium sulfide (NH 4 ) 2 S) was dissolved in 100 mL of distilled water, and placed in a magnet for stirring to obtain solution 1. Dissolve 10 mg CIGS nanoparticles in 10 mL of CH 3 In Cl, solution 2 is obtained. Add solution 2 to solution 1 dropwise. The mixed solution was kept at 45 degrees Celsius for 8 hours.

[0029] Then comes the cleaning process: first remove the above liquid, leaving only the following CIGS:Sn solution. Add an equal volume of isopropanol. Centrifuge at 5000 rpm for 10 minutes to discard the supernatant, dissolve the following precipitate in 30 mL of distilled water, and add an equal volume of isopropanol again. Then repeat the cleaning process again (centrifuge at 5000 rpm for 10 minutes. Discard the ...

Embodiment approach 3

[0032] Embodiment 3 In-situ doping of ligand exchange of Sn element (Na 4 Sn 2 S 6 )

[0033] Step 1: Synthesis of CIGS nanoparticles

[0034] Same as the method described in Step 1 in Embodiment 1.

[0035] Step two exchange ligands

[0036] 28.8g of aqueous sodium sulfide (Na 2 The S·9H2O) solid was dissolved in 80 mL of distilled water, heated to 45 degrees Celsius, and placed in a magnet for stirring to obtain solution 1. 10.51g of water-containing tin chloride (SnCl 4 ·5H2O) The solid was dissolved in 20 mL of distilled water to obtain solution 2. Add solution 2 to solution 1 dropwise. The mixed solution was kept at 45 degrees Celsius for 8 hours.

[0037] Stop heating and add 50 mL methanol solution (or 100 mL acetone solution) to the mixed solution after cooling. (You can stir for another 8 hours. If you find a white precipitate, just remove the transparent liquid on it.) Then store in the refrigerator for 48 hours. White crystals of sodium thiostannide (Na 4 Sn 2 S 6 ). Use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com