A metal-free photocatalytic material for efficient reduction of carbon dioxide

A photocatalytic material, non-metallic technology, applied to carbon monoxide, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of high cost and inefficiency, and achieve mechanical wear resistance, low cost and easy preservation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The preparation steps of the present invention are as follows:

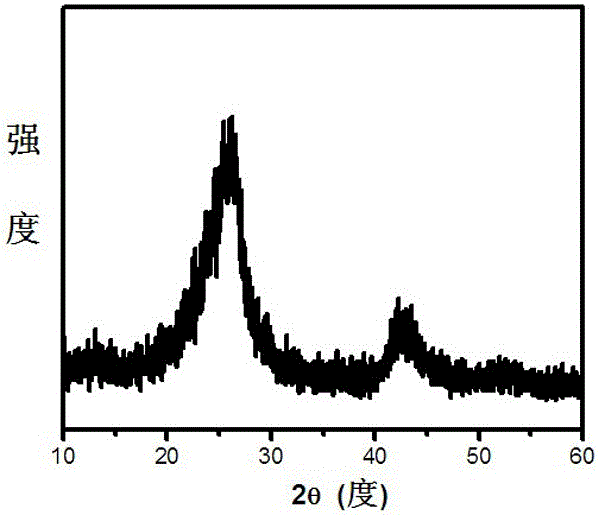

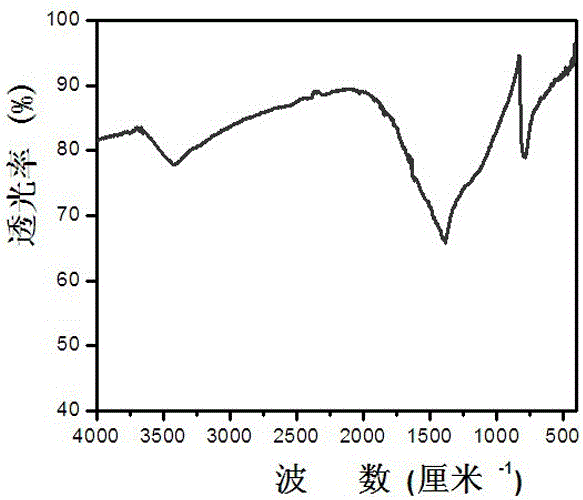

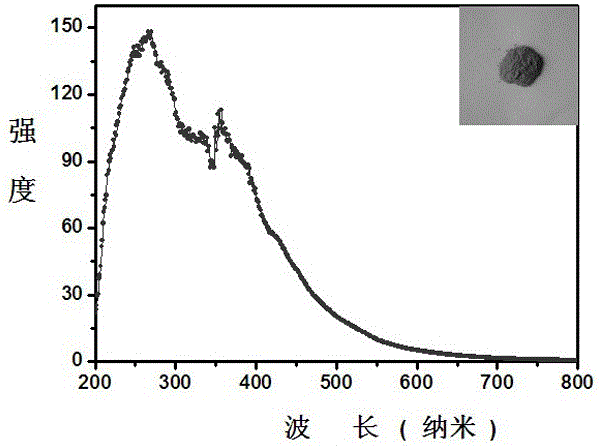

[0017] After boron oxide, urea, and glucose are mixed and ground evenly according to the mass ratio of 1:2:0.3, the mixed sample is taken in a corundum magnetic boat, and then placed in a horizontal high-temperature tube furnace. Under an ammonia atmosphere, Raise the temperature to 1250°C at a rate of 5-10°C / min and keep it for 4-8 hours; take out the sample and wash it with 0.1mol / L dilute hydrochloric acid, centrifuge and dry to obtain graphite phase boron carbon nitrogen powder. Accurately weigh 50 mg of the prepared powder catalyst and place it in a photocatalytic reaction device for photocatalytic reduction of carbon dioxide performance test.

Embodiment 1

[0019] After boron oxide, urea, and glucose are mixed and ground evenly in a mass ratio of 1:2:0.3, the mixed sample is taken in a corundum magnetic boat, and then placed in a horizontal high-temperature tube furnace. Then, the temperature was raised to 1250°C at a speed of 5°C / min and kept for 4 hours; the sample was taken out and washed with 0.1mol / L dilute hydrochloric acid, centrifuged and dried to obtain graphite phase boron carbon nitrogen powder. Accurately weigh 50 mg of the prepared powder catalyst and place it in a photocatalytic reaction device for photocatalytic reduction of carbon dioxide performance test.

Embodiment 2

[0021] After boron oxide, urea, and glucose are mixed and ground evenly in a mass ratio of 1:2:0.3, the mixed sample is taken in a corundum magnetic boat, and then placed in a horizontal high-temperature tube furnace. The temperature was raised to 1250°C at a rate of 10°C / min and maintained for 6 hours; the sample was taken out and washed with 0.1mol / L dilute hydrochloric acid, centrifuged and dried to obtain graphite phase boron carbon nitrogen powder. Accurately weigh 50 mg of the prepared powder catalyst and place it in a photocatalytic reaction device for photocatalytic reduction of carbon dioxide performance test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com