Dimethyl malonate preparation method

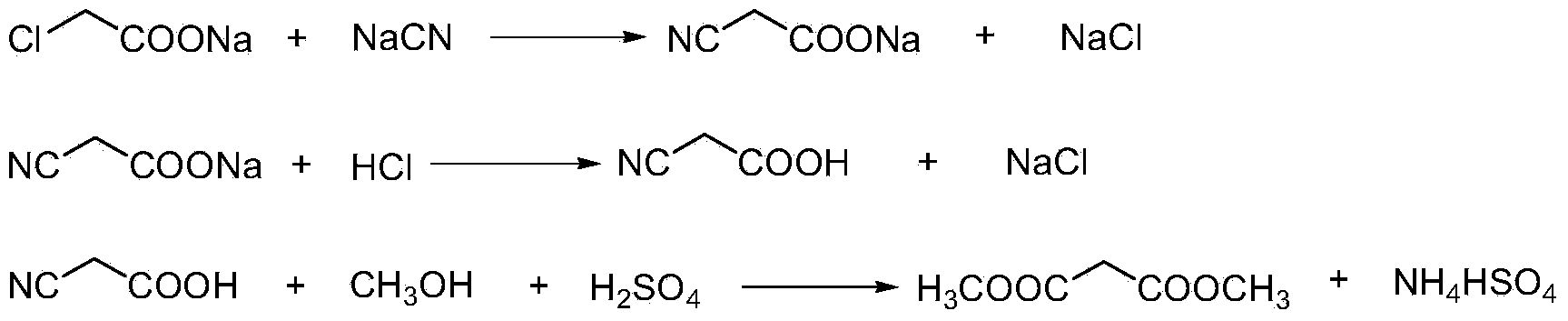

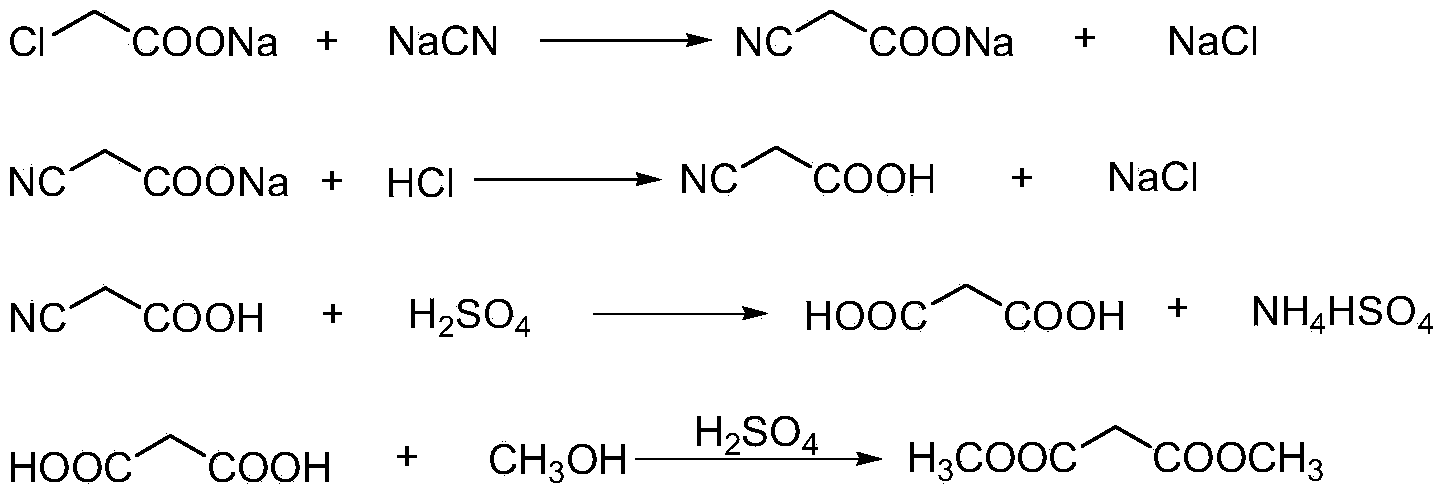

A technology of dimethyl malonate and cyanoacetic acid, which is applied in the preparation of carboxylic acid esters, carboxylic acid nitriles, nitriles, etc., and can solve the problems of consumption of sulfuric acid acid wastewater, poor stirring and heat transfer effects, and easy decomposition of cyanoacetic acid, etc. problem, to avoid a large amount of decomposition and reduce the amount of waste water produced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

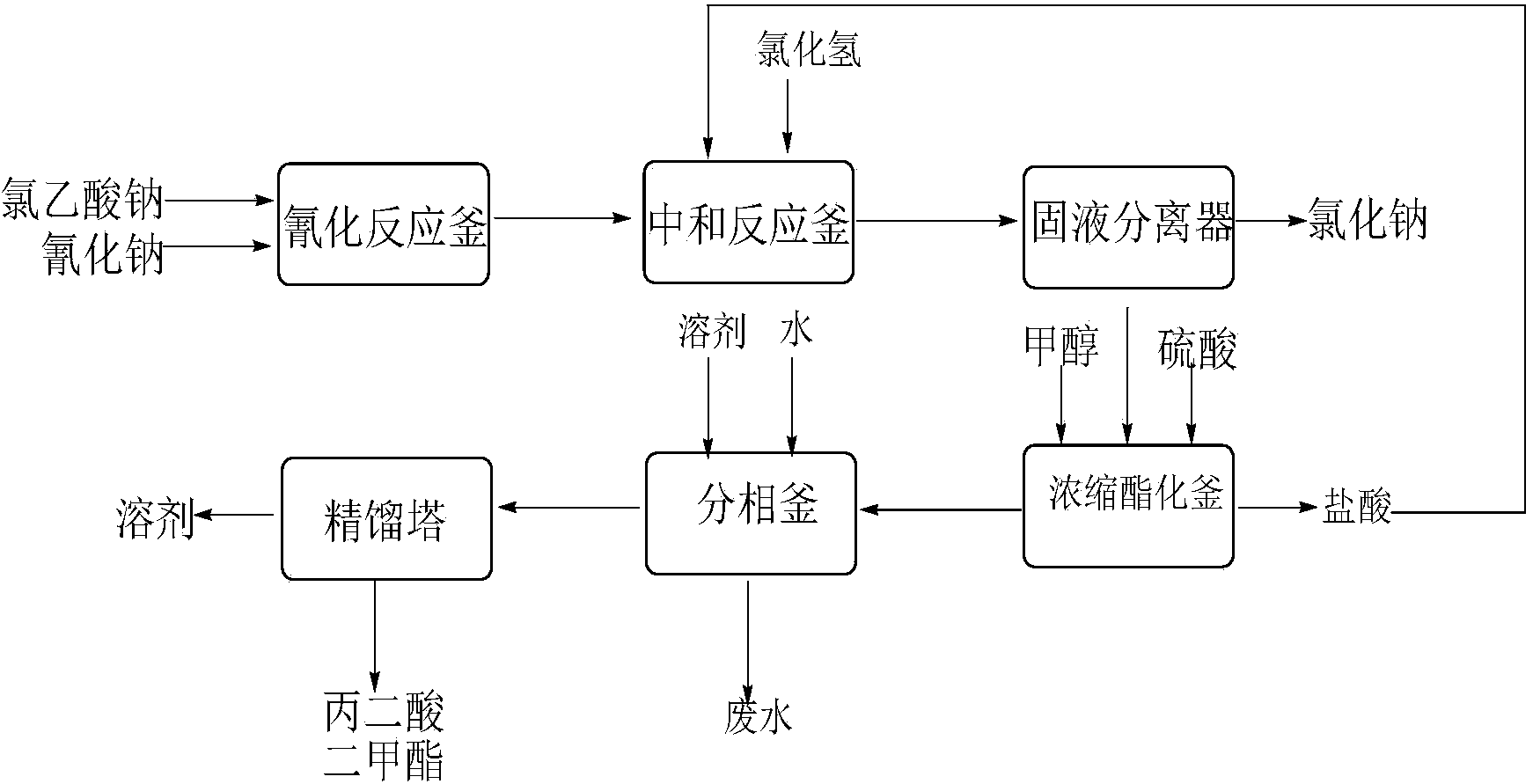

[0028] Embodiment 1: refer to figure 1 , the present invention is further described:

[0029] (1) Neutralization reaction: add 900kg of chloroacetic acid (content 98%, 9.30kmol) to 620kg of water, stir and dissolve, neutralize with aqueous sodium carbonate to pH=6.5-7.0, and generate sodium chloroacetate;

[0030] (2) Cyanide reaction: transfer the sodium chloroacetate obtained in step (1) into the cyanide reaction kettle, raise the temperature to 50°C, then add 1530kg (4.69kmol) of 30% sodium cyanide aqueous solution dropwise, when the reaction temperature reaches 85 After -90°C, stop heating and start to cool. When the reaction temperature reaches 105°C, the reaction ends and is cooled to room temperature to obtain an aqueous solution of sodium cyanoacetate;

[0031] (3) Acidification reaction: transfer the sodium cyanoacetate aqueous solution obtained in step (2) into the acidification reaction kettle, stir, pass in hydrogen chloride gas until the content is 25%, press fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com