Perfluoropolyether, touch screen and fingerprint-proof membrane containing perfluoropolyether membrane and preparation thereof

A technology of perfluoropolyether and anti-fingerprint film, which is applied in the field of perfluoropolyether, can solve the problems of large surface static friction coefficient, high deposition temperature, and difficult control of thickness, and achieve good anti-fingerprint performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

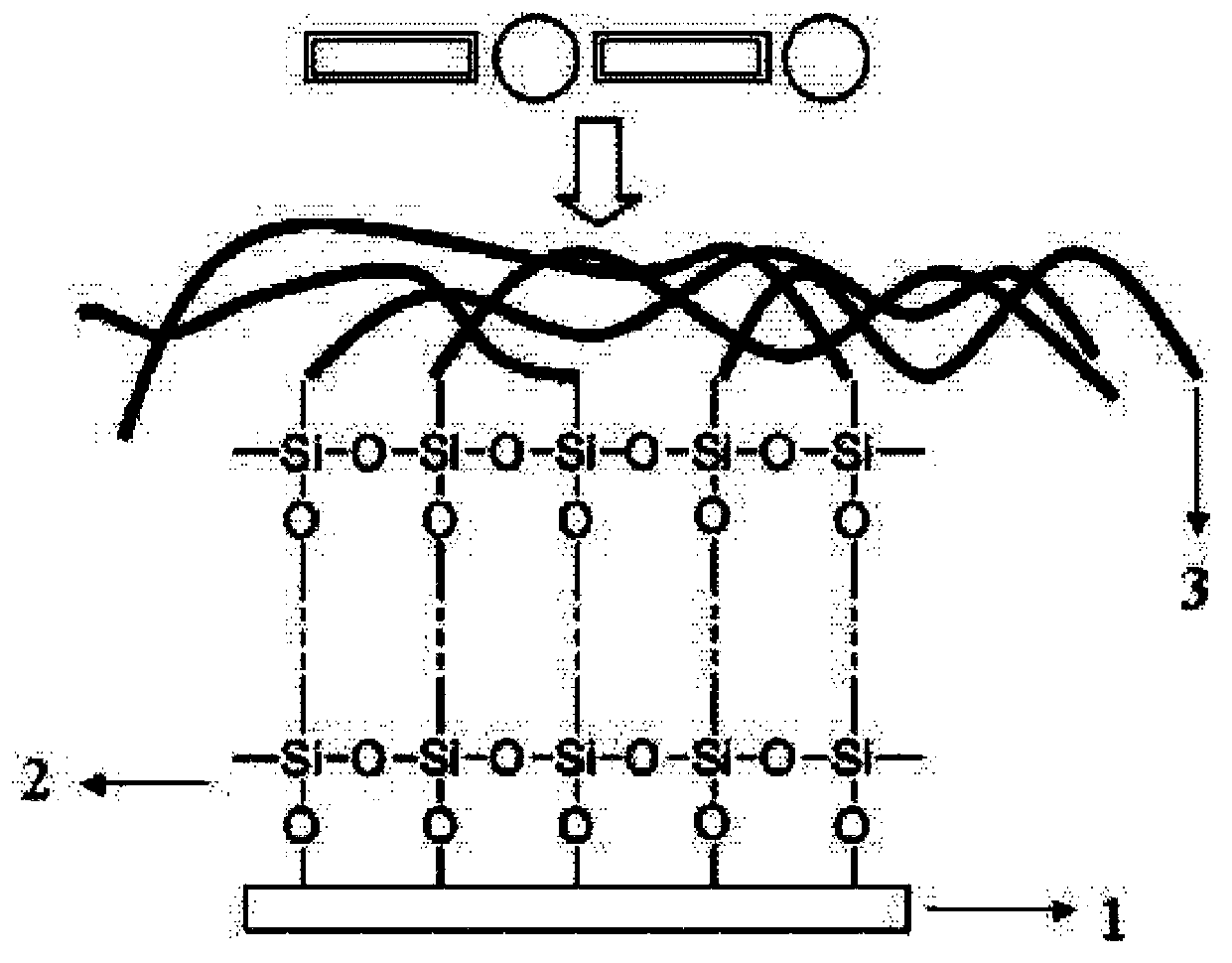

[0025] The synthesis method comprises the following steps: providing a fluoride salt and a polar solvent mixture; adding tetrafluorooxetane to make a catalytic amount of fluorine negative ion react with the tetrafluorooxetane at a certain temperature; Distillation, by controlling the vacuum degree and distillation temperature, the perfluoropolyether material with the required degree of polymerization is collected.

[0026] The polar solvent can adopt diglyme or similar property solvent. The reaction temperature is -30°C to 100°C.

[0027] The synthesis reaction can be represented by the following formula, where the initiator CsF can be replaced by KF or other suitable fluoride salts.

[0028]

[0029] Compared with the common perfluoropolyether material synthesized from hexafluoropropylene oxide, the perfluoropolyether material of the present invention has a unique structure and has better anti-fingerprint performance when applied to the anti-fingerprint coating of the tou...

Embodiment 1

[0045] 113g KF and 1960g diglyme were added to a 2 gallon (7571ml) stainless steel reactor, stirred and cooled to -17°C. 1485 g (8.95 mols) of tetrafluoro oxetane (molecular weight 166.0) were added within one hour, at which point the reaction temperature rose to -4°C and the pressure rose to 28 KPa. The reaction mixture was stirred for 30 minutes and allowed to warm to room temperature. 7350 g of the bottom fluorochemical phase were recovered. Low-boiling components were removed by distillation under reduced pressure, and components at 150-170 degrees (150mmHg) were collected to obtain perfluoropolyether materials with a degree of polymerization of 20-25.

Embodiment 2

[0047] 139g KF and 1960g diglyme were added to a 2 gallon (7571ml) stainless steel reactor, stirred and cooled to -17°C. 1485 g (8.95 mols) of tetrafluoro oxetane (molecular weight 166.0) were added within one hour, at which point the reaction temperature rose to -4°C and the pressure rose to 28 KPa. The reaction mixture was stirred for 30 minutes and allowed to warm to room temperature. 7400 g of the bottom fluorochemical phase were recovered. Low-boiling components were removed by distillation under reduced pressure, and components at 130-150 degrees (150 mmHg) were collected to obtain a perfluoropolyether material with a degree of polymerization of 15-20.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com