Halogen-free flame retardant organosilane self-crosslinked polyolefin cable material and preparation method thereof

A polyolefin cable material, self-crosslinking technology, used in circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problem of high requirements for extrusion equipment and extrusion process, affecting the electrical properties and flame retardant properties of materials , product quality is not easy to control and other problems, to achieve the effect of inhibiting catalytic aging, convenient and flexible processing technology, and good flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A halogen-free flame retardant silane self-crosslinking polyolefin cable material is composed of A material, B material and C material;

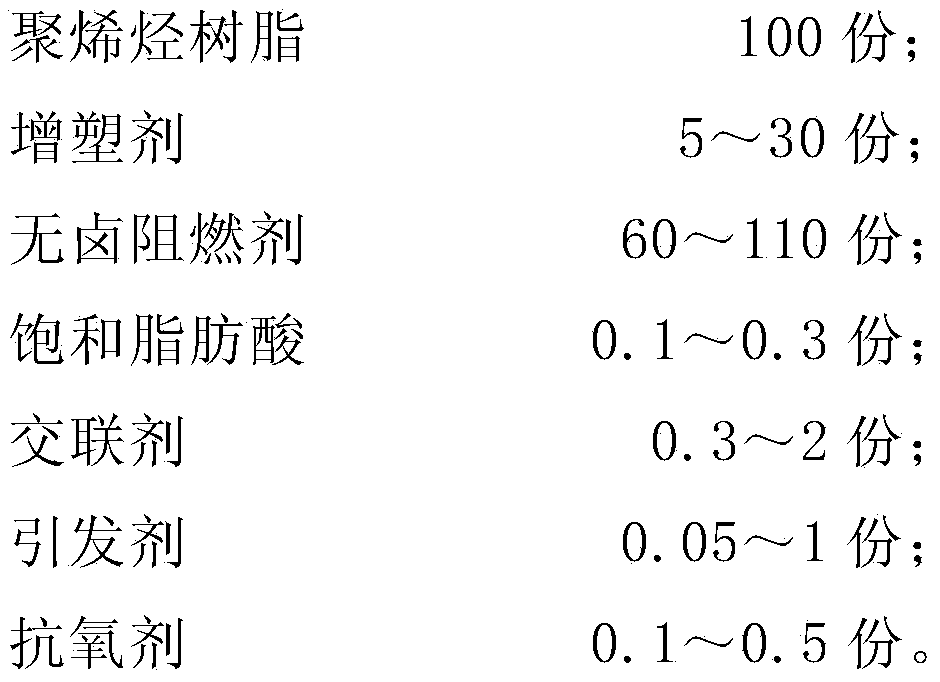

[0042] The composition and parts by weight of material A are:

[0043]

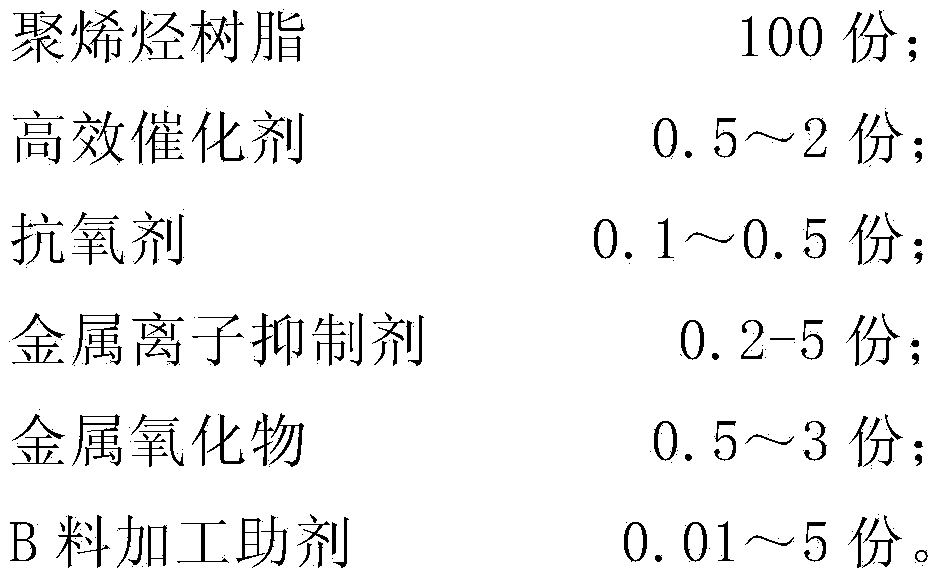

[0044] The composition and parts by weight of material B are:

[0045]

[0046]

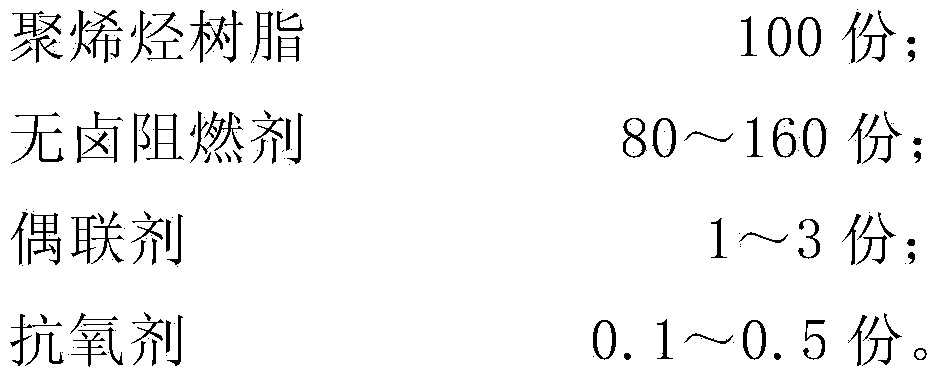

[0047] The composition of material C and the parts by weight are:

[0048]

[0049] The preparation method of a halogen-free flame-retardant silane self-crosslinking polyolefin cable material of this embodiment includes the following steps:

[0050] (1) Preparation of material A

[0051] Linear low density polyethylene, high density polyethylene, ethylene vinyl acetate copolymer and maleic anhydride grafted vinyl acetate copolymer polyolefin resin raw materials are weighed according to the proportion, poured into a high mixer and stirred for 5 to 10 minutes. After uniform, it is fed by the main feeding system of the double-stage twin-screw extruder through the loss-in...

Embodiment 2

[0058] A halogen-free flame retardant silane self-crosslinking polyolefin cable material is composed of A material, B material and C material. The components and parts by weight of A material are:

[0059] The composition and parts by weight of material A are:

[0060]

[0061] The composition and parts by weight of material B are:

[0062]

[0063]

[0064] The composition of material C and the parts by weight are:

[0065]

[0066] The preparation method of the halogen-free flame-retardant silane self-crosslinking polyolefin cable material of this embodiment includes the following steps:

[0067] (1) Preparation of material A

[0068] Linear low density polyethylene, high density polyethylene, ethylene vinyl acetate copolymer and maleic anhydride grafted vinyl acetate copolymer polyolefin resin raw materials are weighed and proportioned, poured into a high mixer and stirred for 5 to 10 minutes. After mixing uniformly, it is fed by the main feeding system of t...

Embodiment 3

[0075] A halogen-free flame retardant silane self-crosslinking polyolefin cable material is composed of A material, B material and C material. The components and parts by weight of A material are:

[0076] The composition and parts by weight of material A are:

[0077]

[0078] The composition and parts by weight of material B are:

[0079]

[0080]

[0081] The composition of material C and the parts by weight are:

[0082]

[0083] The preparation method of the halogen-free flame-retardant silane self-crosslinking polyolefin cable material of the embodiment includes the following steps:

[0084] (1) Preparation of material A

[0085] Linear low density polyethylene, high density polyethylene, ethylene vinyl acetate copolymer and maleic anhydride grafted vinyl acetate copolymer polyolefin resin raw materials are weighed and proportioned, poured into a high mixer and stirred for 5 to 10 minutes. After mixing uniformly, it is fed by the main feeding system of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com