Growing apparatus and method for Ti sapphire crystal

A technology of crystal growth, titanium sapphire, applied in the direction of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of crystal cracking, affecting crystal quality, existence of mosaic structure, etc., to overcome the limitation of crystal diameter, improve the speed and quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

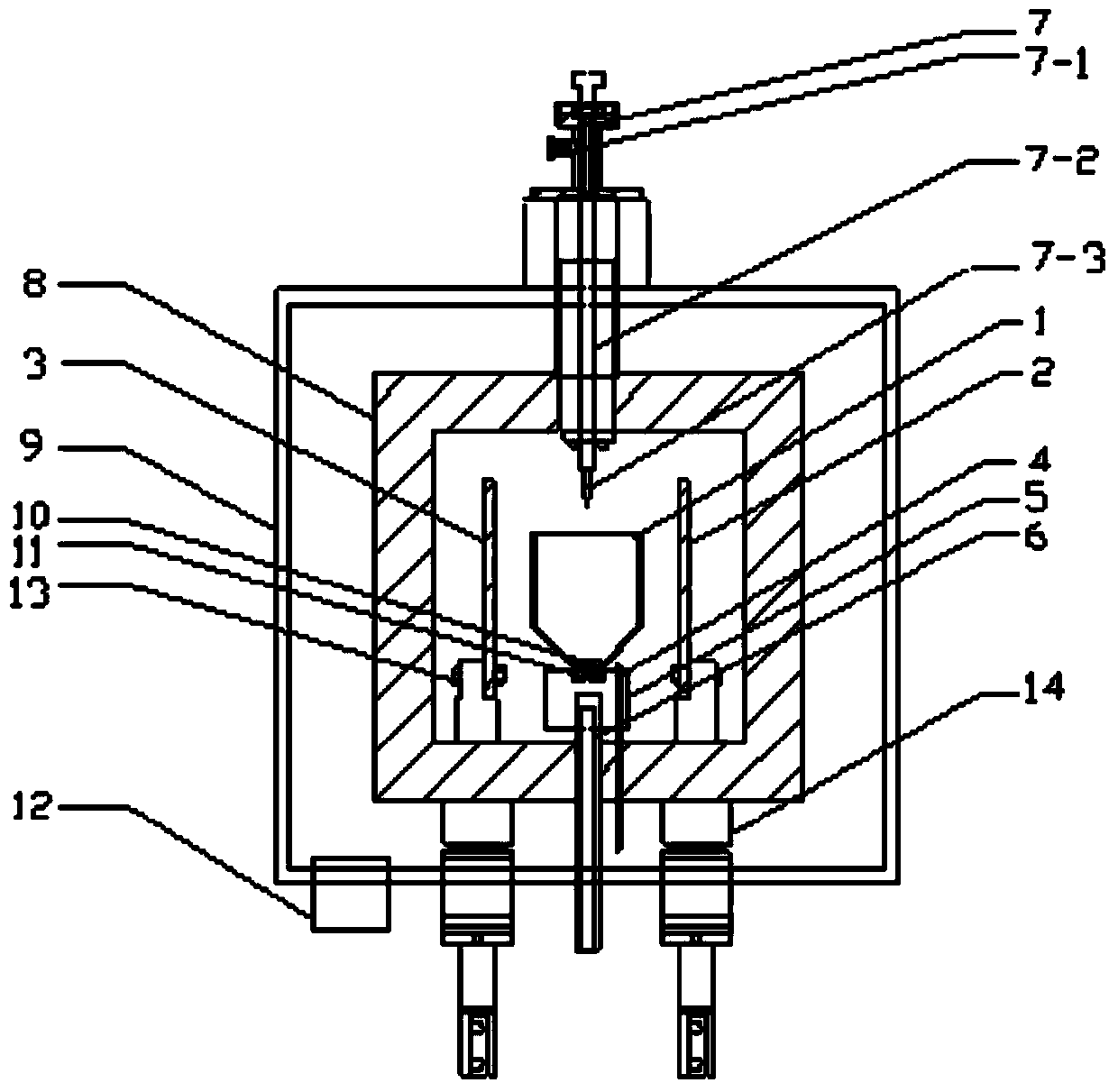

[0037] The growth of titanium sapphire crystal is carried out by using the above-mentioned titanium sapphire crystal growth device and the process steps of growing titanium sapphire crystal

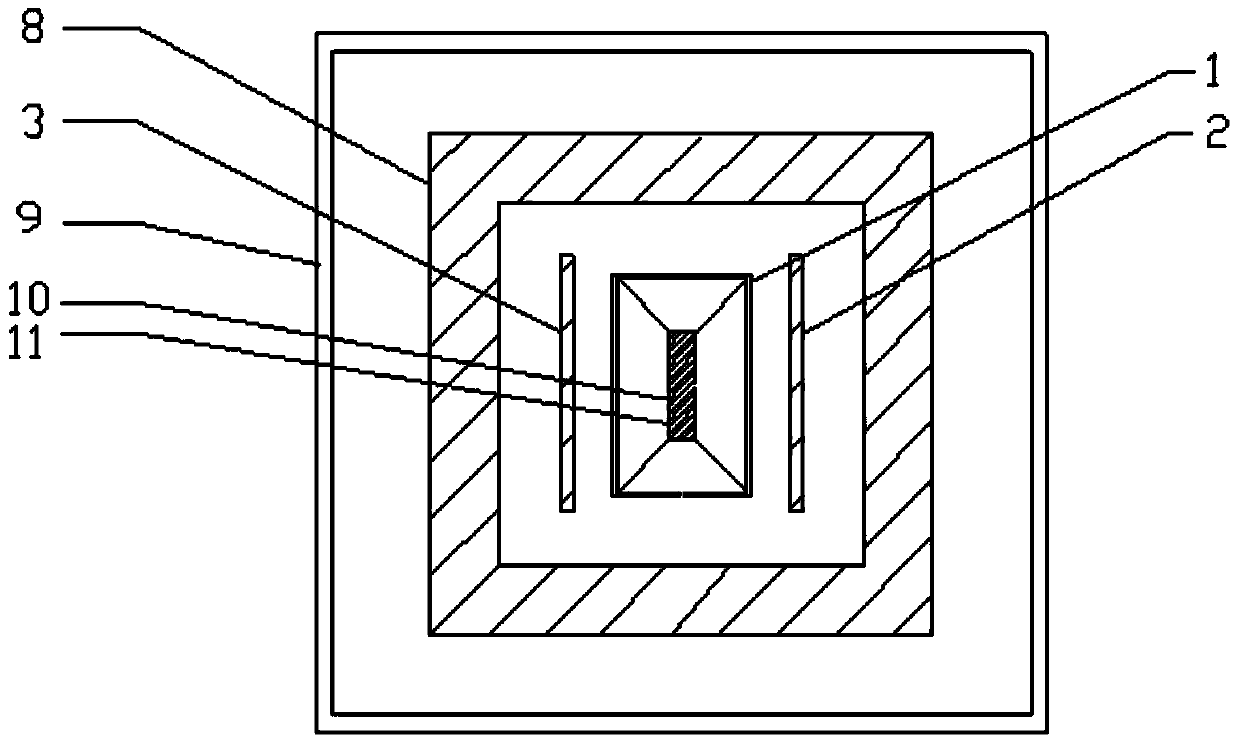

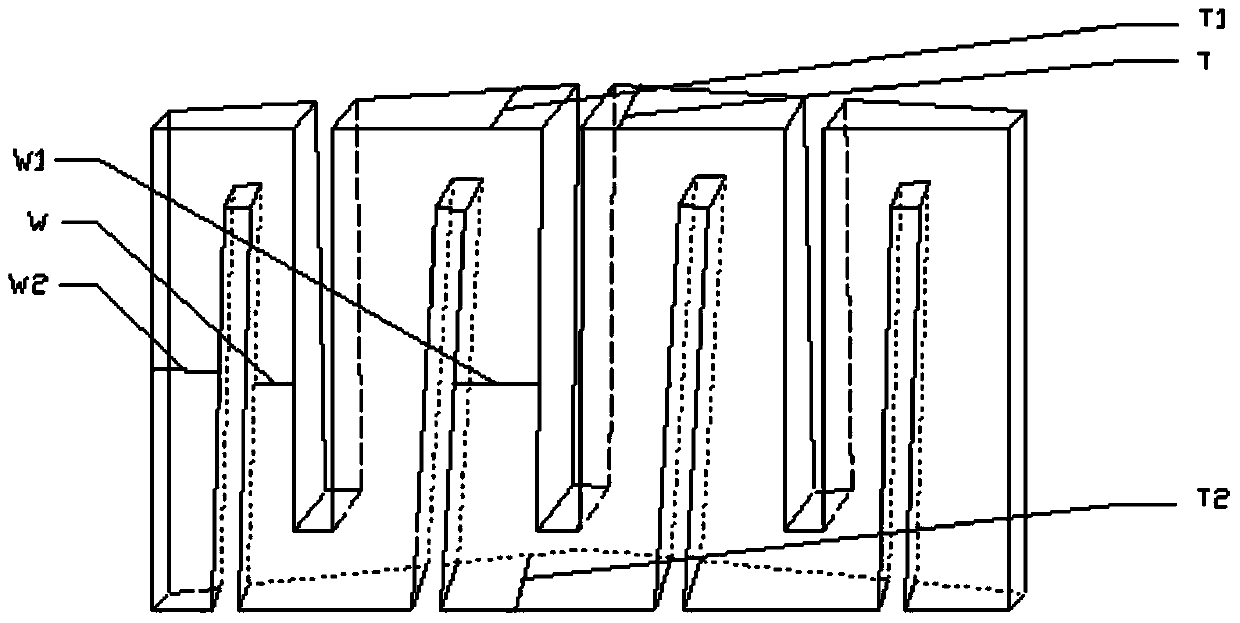

[0038] Molybdenum crucible 10 length 140 × width 110 × height 140mm 3 , the wall thickness of the crucible is 3.5mm, with a square seed crystal groove 11 deep 4×width 10×length 50mm in the center of the bottom 3 square cone crucible. The graphite heater is a Z-shaped plate, and the heat preservation device is graphite hard felt. The A-oriented titanium sapphire slab seed crystal is used. 7.5kg of titanium sapphire raw material is loaded into the crucible with the seed crystal matching the seed crystal groove 11 installed at the bottom. Adjust the positions of the crucible and the thermocouple, turn on the vacuum system 12 after the furnace is installed, and raise the temperature to 1480°C while evacuating. When the vacuum in the furnace body 9 reaches 3×10 -3 After Pa, fill with high-...

Embodiment 2

[0040] The crystal growth device used in this embodiment is the same as that of Embodiment 1, using a length 280×width 140×height 160mm 3 , a crucible with a wall thickness of 3.5mm, with a square seed crystal groove in the center of the bottom 11 deep 4×width 15×length 120mm 3 square cone crucible. The graphite heater is a Z-shaped plate, and the heat preservation device is graphite hard felt. The A-oriented titanium sapphire slab seed crystal is used. 20.5kg of titanium sapphire raw material is packed into the crucible with the seed crystal matching the seed crystal tank 11 installed at the bottom. Adjust the positions of the crucible and the thermocouple, turn on the vacuum system 12 after the furnace is installed, and raise the temperature to 1480°C while evacuating. When the vacuum in the furnace body 2 reaches 3×10 -3 After Pa, fill it with high-purity argon gas protection, continue to heat up to 2060 ° C, start the seed crystal probe lifting mechanism to detect the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com