Integrated one-time forming method of amorphous and nano-crystal magnetic powder cores

An integral molding, nanocrystalline technology, applied in the direction of magnetic core/yoke, inductor/transformer/magnet manufacturing, electrical components, etc., to achieve the effect of convenient use, simple mold structure, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Sieve the prepared cobalt-based amorphous magnetic powder to obtain magnetic powder with different particle sizes, add 3% oleic acid and stir evenly, and pack it after drying; fully mix the amorphous magnetic powder with binder (organic binder, inorganic binder) After mixing, weigh and pour it into the rod-shaped component mold (the inner wall of the mold is coated with a release agent such as lubricating oil in advance), and press it into a cobalt-based amorphous powder magnetic core with a specific specification and shape under a pressure of 9MPa with a rod-shaped component mold, heat treatment Eliminate stress, paint the surface or cover with plastic casing, etc., then perform performance testing and package the finished product;

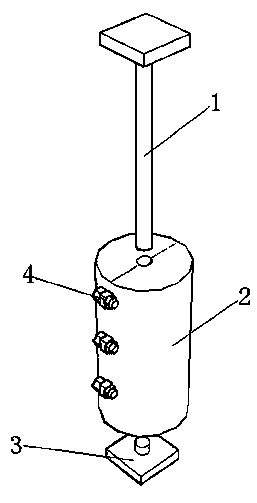

[0015] Among them, the rod-shaped component mold includes a press tool 1, a set mold 2, a base 3 and a fastener 4. The set mold 2 is a columnar structure with a circular cavity. The upper end of the set mold 2 is connected with the press to...

Embodiment 2

[0017] Sieve the prepared iron-based amorphous and nanocrystalline magnetic powders to obtain magnetic powders of different particle sizes, add 2% oleic acid and stir evenly for later use, and pack after drying; mix amorphous and nanocrystalline magnetic powders with binders (organic binders, Inorganic binder) is fully mixed, weighed and poured into the ring-shaped component mold (the inner wall of the mold is coated with a release agent such as lubricating oil in advance), and pressed into a non-standard shape with a ring-shaped component mold under a pressure of 15MPa. Crystalline and nanocrystalline powder magnetic cores, heat treatment to eliminate stress, the surface is painted or covered with plastic shells and other packaging treatments, and then performance testing is carried out, and the finished product is packaged;

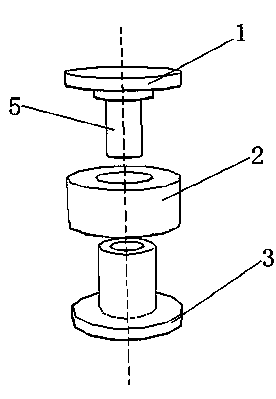

[0018] Among them, the ring-shaped element mold includes a press tool 1, a sleeve mold 2, a base 3 and a central shaft 5, the lower part of the press to...

Embodiment 3

[0020] Sieve the prepared iron-nickel-based amorphous alloy magnetic powder to obtain magnetic powder of different particle sizes, add 4.5% oleic acid and stir evenly, and pack it after drying; the amorphous magnetic powder and binder (organic binder, inorganic binder ) After fully mixed, weigh and pour into the E-shaped component mold (the inner wall of the mold is coated with a release agent such as lubricating oil in advance), and press the E-shaped component mold under a pressure of 18MPa to form a specific specification E-shaped cobalt-based amorphous powder magnet. Core, heat treatment to relieve stress, the surface is painted or covered with plastic casing and other packaging treatment, then performance testing, finished product packaging;

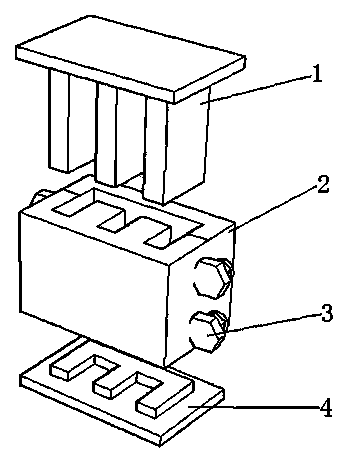

[0021] Among them, the E-shaped component mold includes a press tool 1, a cover mold 2, a base 3 and a fastener 4. There is an E-shaped communicating cavity in the cover mold 2. The lower part of the press tool 1 and the upper part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com