Composite semiconductor photocatalyst and application thereof

A compound semiconductor and photocatalyst technology, applied in the field of photocatalytic materials, can solve problems such as ineffective effects, and achieve the effects of improving dispersion, reducing particle size, and reducing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Tetraethyl titanate and mercaptobutanol were mixed at a mass ratio of 33:67, reacted at 70°C for 5 h, and distilled under reduced pressure (temperature 40°C, pressure -0.1 Mpa) to remove ethanol to obtain tetramercaptobutanol titanate ( titanium dioxide precursor); mix tetramercaptobutanol titanate, anhydrous cadmium acetate, and absolute ethanol at a mass ratio of 20:41.6:38.4, react at 30°C for 2 h, and remove ethanol by vacuum distillation (temperature 40°C, Pressure -0.1 Mpa) to obtain the precursor solution.

[0027] The precursor solution, polyethylene glycol and absolute ethanol were mixed according to the mass ratio of 29.5: 0.1: 70.4, stirred and reacted at 20 rpm at 25 °C for 1 h, and the ethanol was removed by vacuum distillation (temperature 40 °C, pressure -0.1 Mpa), Get the gel.

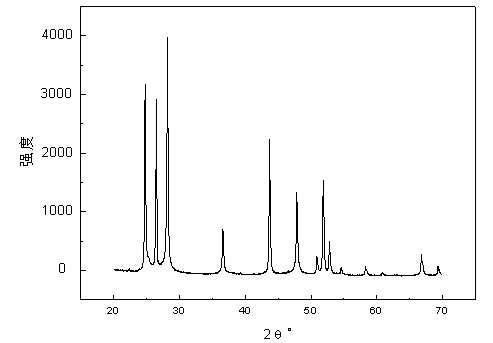

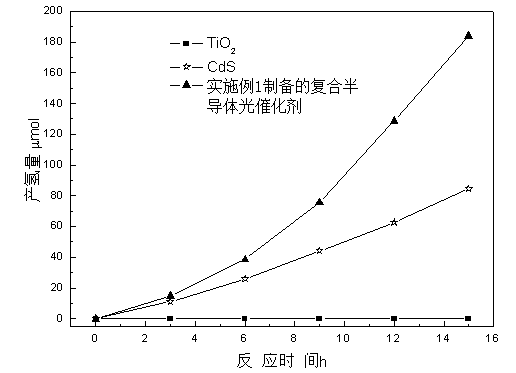

[0028] The gel was treated under nitrogen protection: calcined at 200 °C for 3 h, at 300 °C for 3 h, at 400 °C for 3 h, and at 480 °C for 3 h. The gel is treated under the prot...

Embodiment 2

[0031] Mix tetraethyl titanate and mercaptobutanol at a mass percentage of 33:90, react at 80°C for 7 h, and remove ethanol by vacuum distillation (temperature 40°C, pressure -0.1 Mpa) to obtain tetramercaptobutanol titanate (Titanium dioxide precursor); mix tetramercaptobutanol titanate, anhydrous cadmium acetate and absolute ethanol at a mass ratio of 34:2:64, react at 40°C for 3 h, and remove ethanol by vacuum distillation (temperature 50°C , pressure -0.09 Mpa), to obtain the precursor solution;

[0032] The precursor solution, polyethylene glycol and absolute ethanol were mixed according to the mass ratio of 29.5: 0.2: 70.3, stirred and reacted at 40 rpm at 30 °C for 2 h, and the ethanol was removed by vacuum distillation (temperature 50 °C, pressure -0.09 Mpa) , to obtain a gel.

[0033] The gel was sequentially processed as follows under the protection of nitrogen: calcined at 200 °C for 5 h, calcined at 300 °C for 5 h, calcined at 400 °C for 5 h, and calcined at 480 °...

Embodiment 3

[0035] Mix tetraethyl titanate and mercaptobutanol at a mass ratio of 33:1, react at 85°C for 8 h, and remove ethanol by vacuum distillation (temperature 40°C, pressure -0.1 Mpa) to obtain tetramercaptobutanol titanate (Titanium dioxide precursor); mix tetramercaptobutanol titanate, anhydrous cadmium acetate and absolute ethanol at a mass ratio of 34:3:63, react at 50°C for 4 h, and remove ethanol by vacuum distillation (temperature 60°C , pressure -0.08 Mpa), to obtain the precursor solution;

[0036] The precursor solution, polyethylene glycol and absolute ethanol were mixed according to the mass ratio of 29.5: 0.3: 70.2, stirred and reacted at 60 rpm at 35 °C for 3 h, and the ethanol was removed by vacuum distillation (temperature 60 °C, pressure -0.08 Mpa) , to obtain a gel.

[0037] The gel was sequentially processed as follows under the protection of nitrogen: calcined at 200 °C for 10 h, calcined at 300 °C for 10 h, calcined at 400 °C for 10 h, and calcined at 480 °C f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com