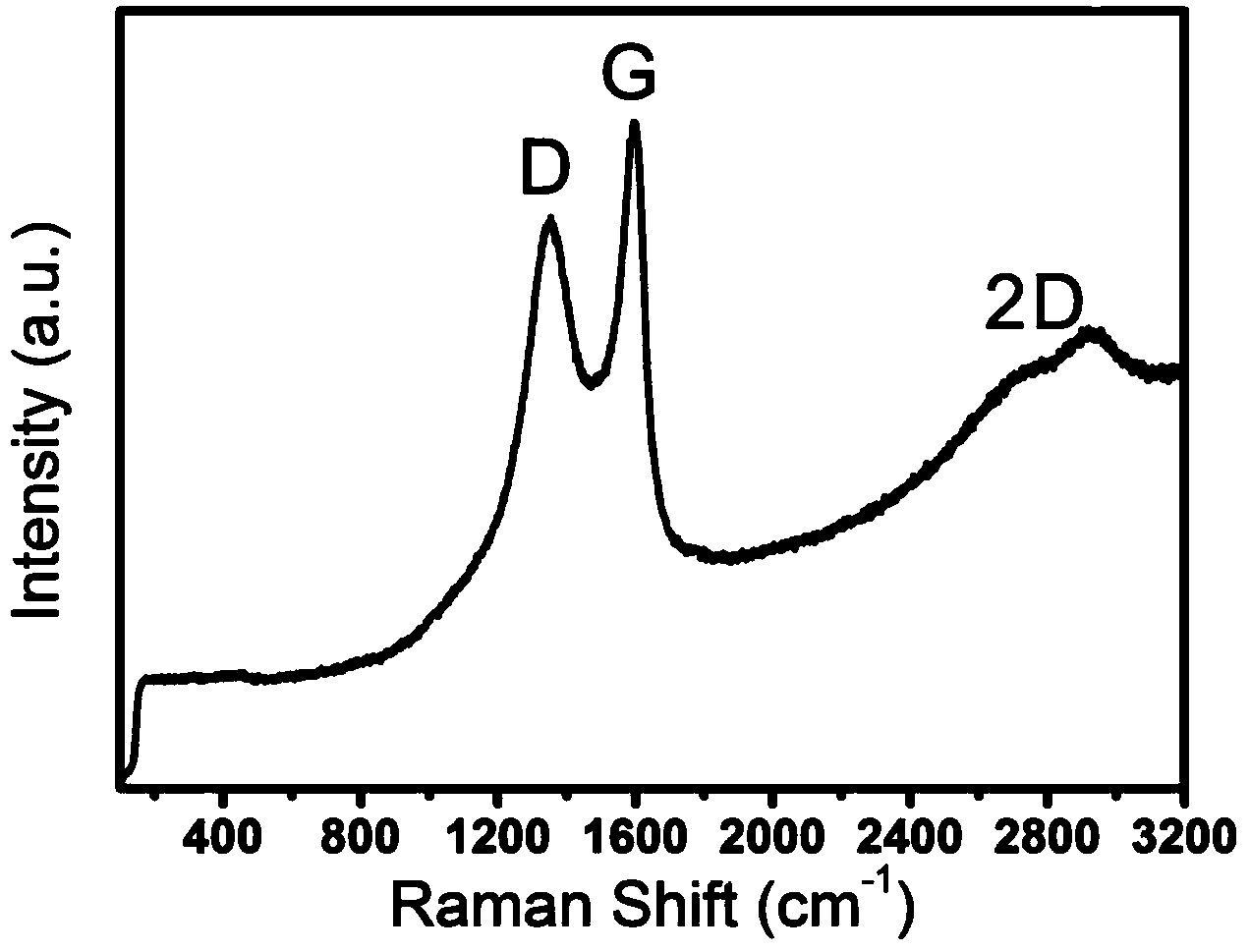

C-14-marked graphene and synthetic method thereof

A technology of C-14 and synthesis method, which is applied in the direction of graphene, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problems of unclear mechanism and uncertainty of nanomaterials retaining their own characteristics, and achieve good results. The effect of reference significance, easy availability of raw materials, and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

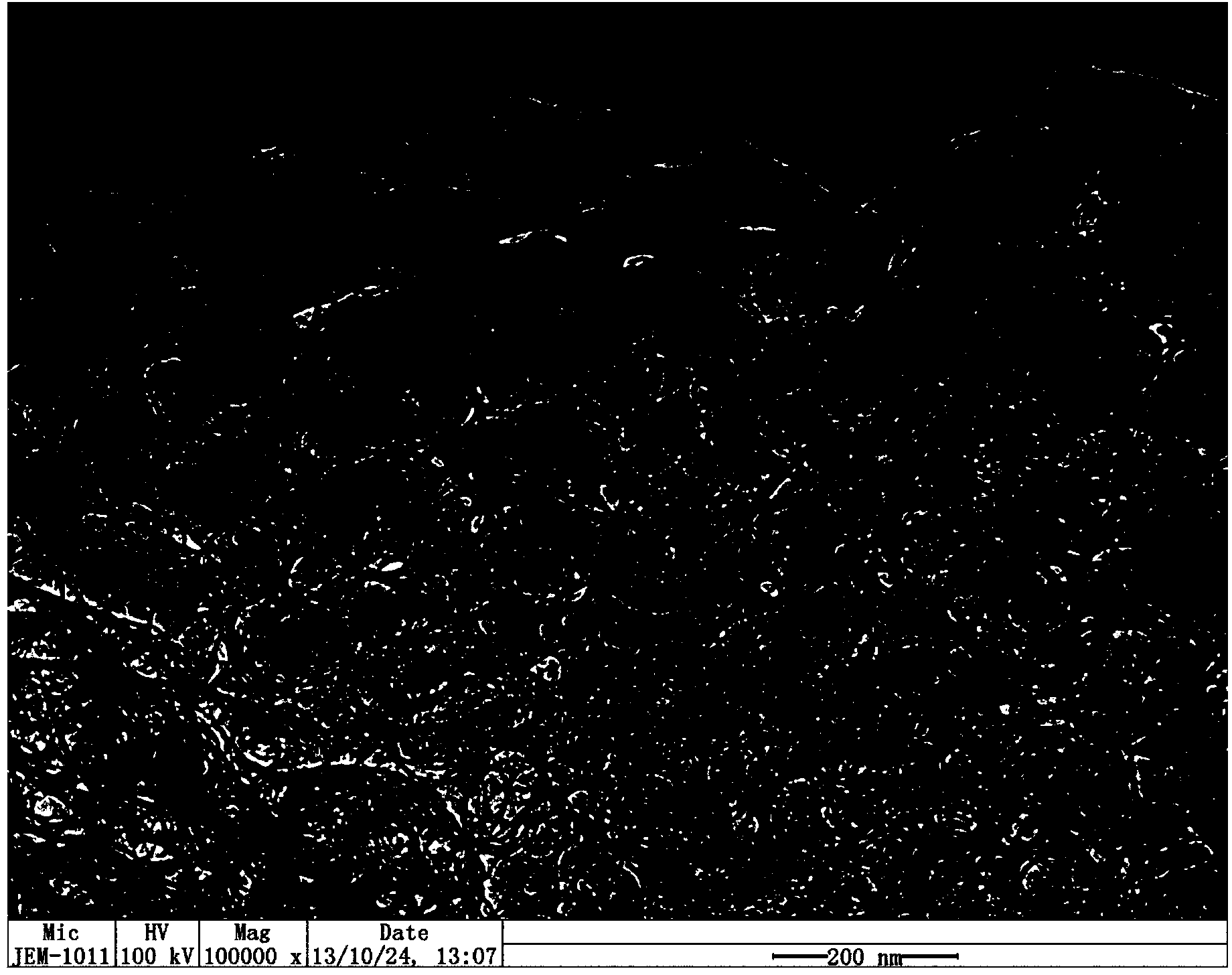

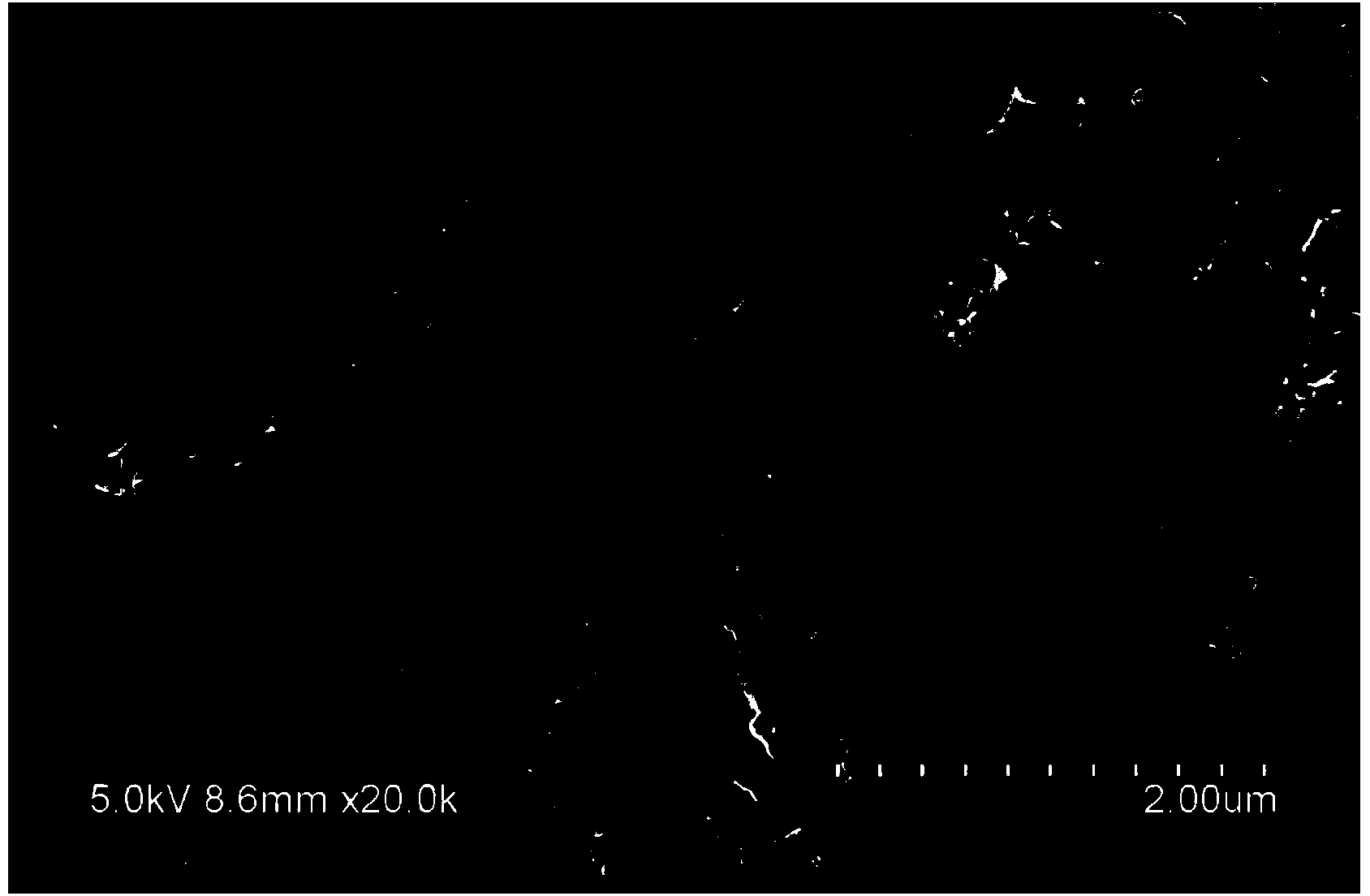

[0028] Present embodiment 1 uses dodecylamine and C-14 labeled phenol to synthesize C-14 labeled graphene, and its steps are:

[0029] (1) Accurately weigh 5g of dodecylamine powder, dissolve it in 20ml of absolute ethanol, weigh 1.590g of ferrous chloride tetrahydrate and 0.900g of ammonium dihydrogen phosphate and dissolve it in 80ml of ultrapure water (dihydrogen phosphate The molar ratio of ammonium to ferrous chloride tetrahydrate is 1:1.02, and the molar ratio of ammonium dihydrogen phosphate to dodecylamine is 1:3.45). In a water bath at 45°C, mix the anhydrous ethanol solution of dodecylamine with the mixed solution of ferrous chloride and ammonium dihydrogen phosphate, collect the solid product by centrifugation, and dry it in vacuum at 40°C for 36 hours. The dried solid product was ground into a powder and placed in a crucible.

[0030] (2) Use a pipette to measure 800 μl of ethanol solution of C-14-labeled phenol (the total radioactivity is 11.99mCi), drop it onto ...

Embodiment 2

[0034] Present embodiment 2 uses dodecylamine and C-14 labeled phenol to synthesize C-14 labeled graphene, and its steps are:

[0035] (1) Weigh 3.62g of dodecylamine powder, dissolve it in 20ml of absolute ethanol, weigh 1.71g of ferrous chloride tetrahydrate and 0.900g of ammonium dihydrogen phosphate and dissolve it in 80ml of ultrapure water (dihydrogen phosphate The molar ratio of ammonium to ferrous chloride tetrahydrate is 1:1.1, and the molar ratio of ammonium dihydrogen phosphate to dodecylamine is 1:2.5). In a water bath at 50°C, mix the anhydrous ethanol solution of dodecylamine with the mixed solution of ferrous chloride and ammonium dihydrogen phosphate, centrifuge to collect the solid product, and dry it in vacuum at 50°C for 24 hours. The dried solid product was ground into a powder and placed in a crucible.

[0036] (2) Use a pipette to measure 400 μl of ethanol solution of C-14-labeled phenol (the total radioactivity is 5.995mCi), drop it onto the powder in t...

Embodiment 3

[0040] This embodiment 3 uses dodecylamine and C-14 labeled phenol to synthesize C-14 labeled graphene, and its steps are:

[0041] (1) Weigh 7.25g of dodecylamine powder, dissolve it in 20ml of absolute ethanol, weigh 1.55g of ferrous chloride tetrahydrate and 0.90g of ammonium dihydrogen phosphate and dissolve it in 80ml of ultrapure water (dihydrogen phosphate The molar ratio of ammonium to ferrous chloride tetrahydrate is 1:1, and the molar ratio of ammonium dihydrogen phosphate to dodecylamine is 1:5). In a water bath at 55°C, mix the anhydrous ethanol solution of dodecylamine with the mixed solution of ferrous chloride and ammonium dihydrogen phosphate, centrifuge to collect the solid product, and dry it in vacuum at 60°C for 12 hours. The dried solid product was ground into a powder and placed in a crucible.

[0042] (2) Use a pipette to measure 100 μl of ethanol solution of C-14-labeled phenol (the total radioactivity is 1.499mCi), drop it onto the powder in the cruci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com