Method for generating and utilizing N2O in partial nitrifying process of sludge digestion solution

A technology of sludge digestion liquid and short-range nitrification, applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc., to improve living environment, reduce greenhouse gas emissions, and save operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

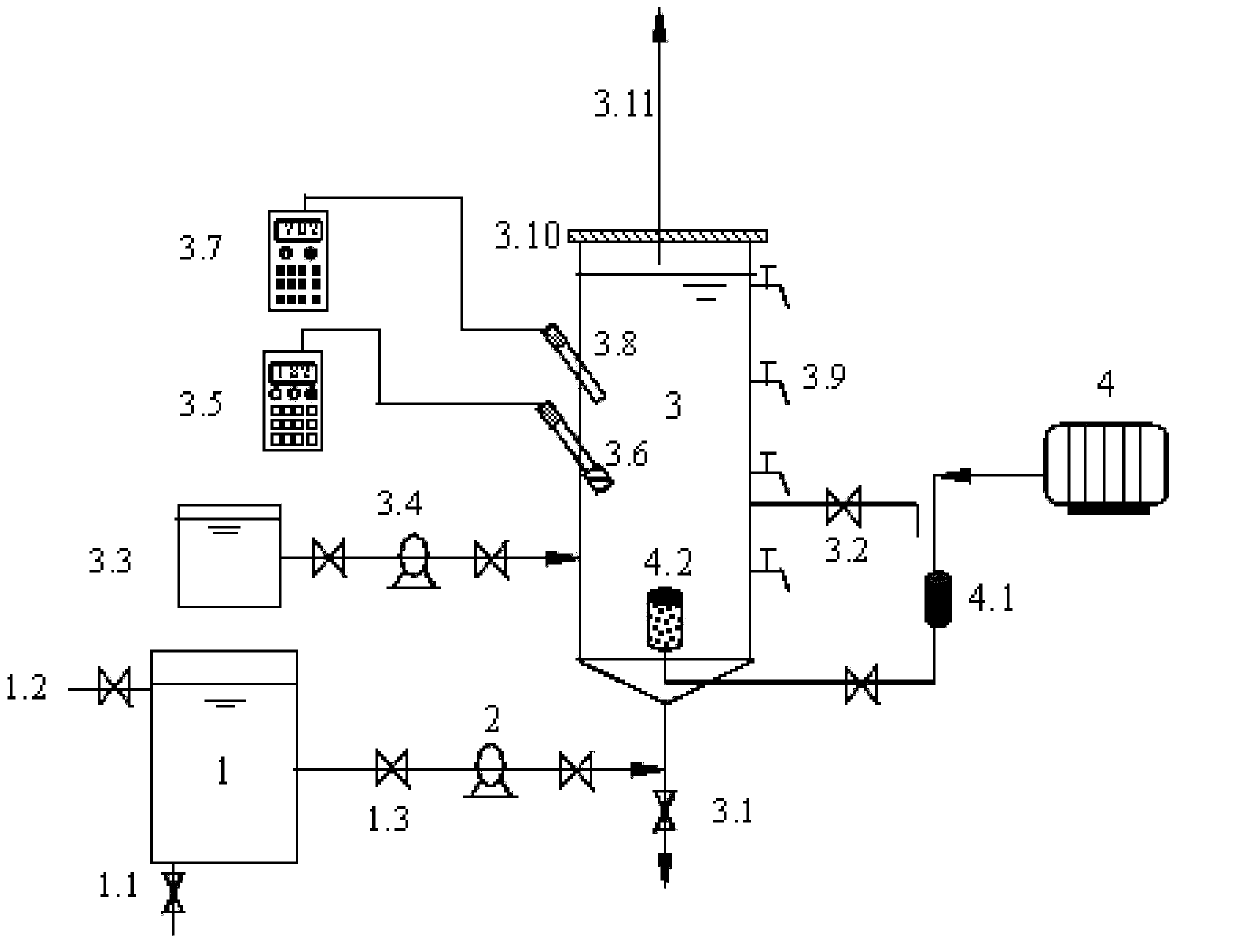

[0028] The present invention will be further described below in conjunction with accompanying drawing and embodiment: As shown in the figure, a kind of N 2 The device used in the method of generation and utilization of O is characterized in that: sludge digestion liquid water tank 1, water inlet pump 2, short-range nitrification to produce N 2 O reactor 3, air compressor 4; Described sludge digestate water tank 1 is an opening casing, is provided with vent pipe 1.1 and overflow pipe 1.2; Described short-range nitrification produces N 2 O reactor 3 is a sealed type SBR, and the reactor top is provided with sealing cover 3.10 and N 2 O collection pipe 3.11, the reactor wall is provided with sampling port and mud discharge port 3.9, outlet pipe 3.2, DO probe 3.6 and pH probe 3.8, dissolved oxygen meter 3.5 and pH meter 3.7 are respectively connected to corresponding probes, the bottom of the reactor There is a vent pipe 3.1; the aeration system is composed of an air compressor 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com