Composite functional material for performing biochemical combined remediation on polluted underwater and preparation method for composite functional material

A composite function, biochemical technology, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc. The effect of great hardness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

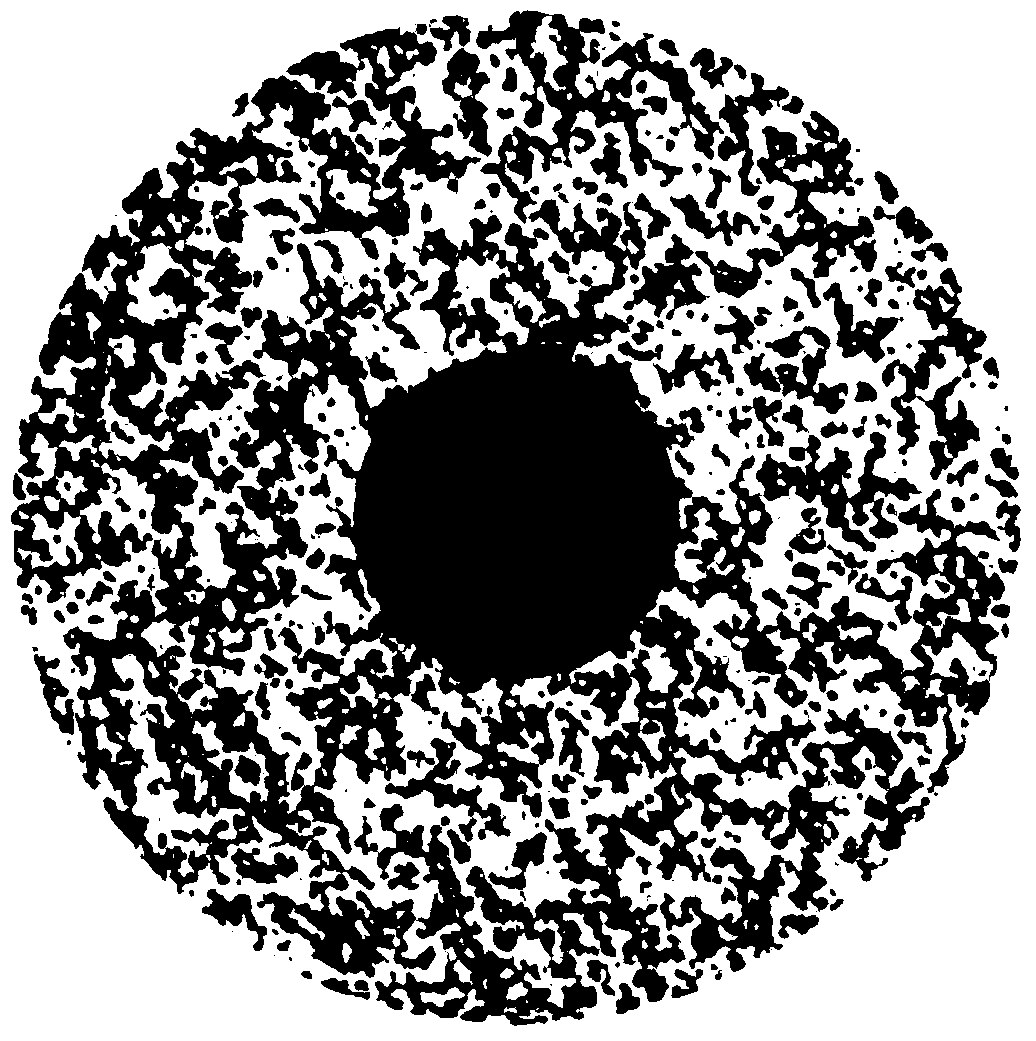

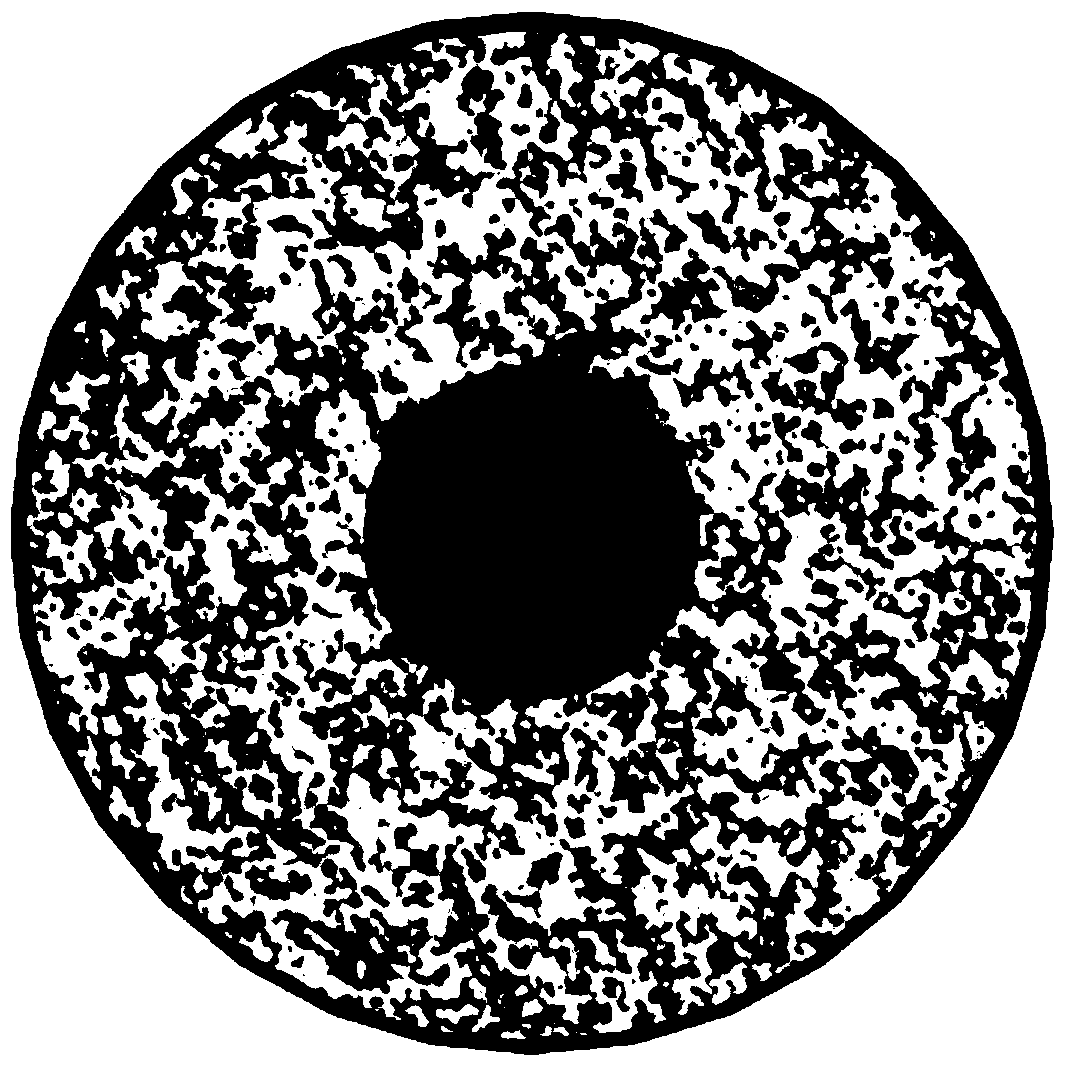

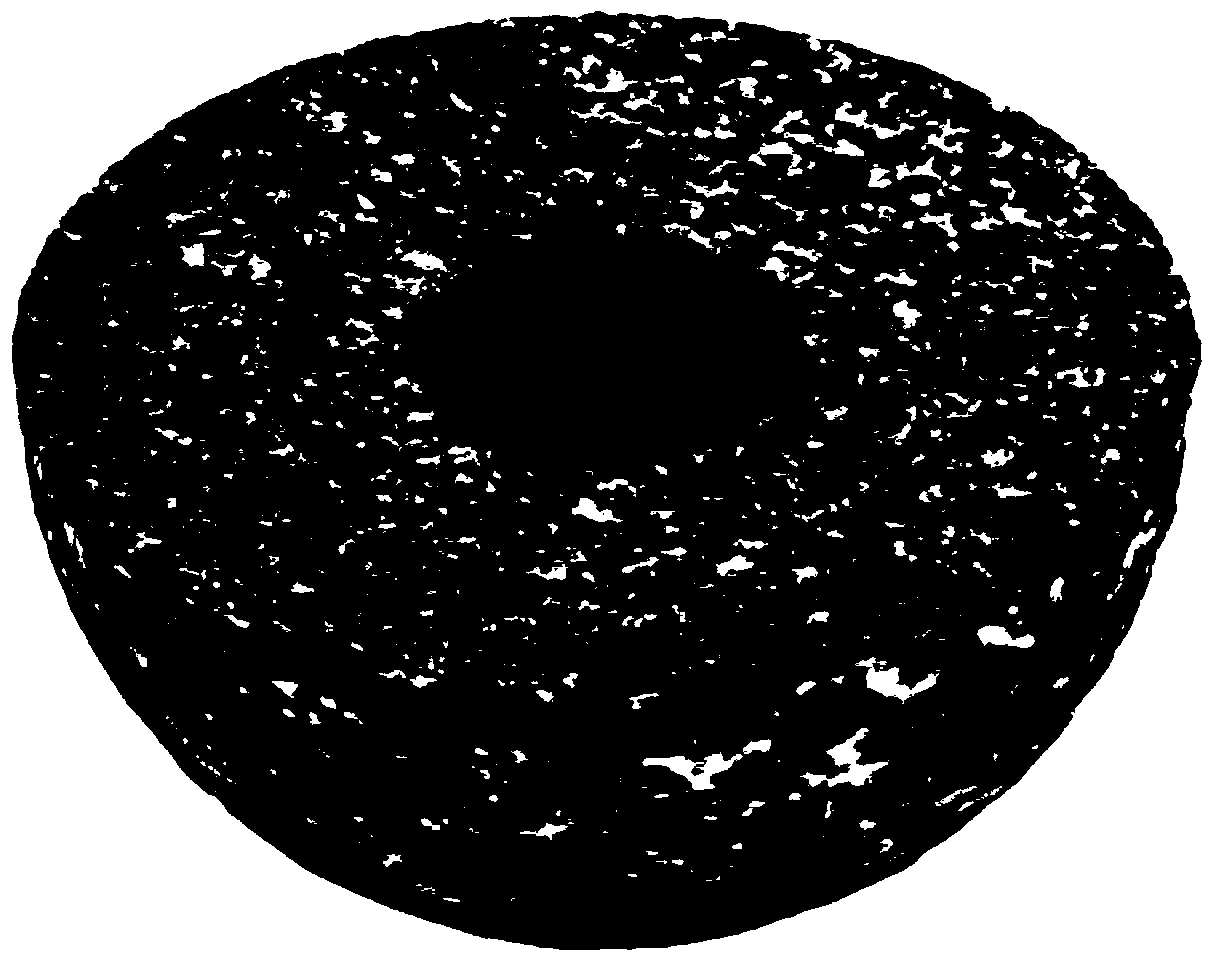

Image

Examples

Embodiment 1

[0039] The composite functional material of this embodiment carries out the principle of biochemical joint restoration of contaminated groundwater: the carbon-releasing raw materials contained in the material filling layer and the inner wood block can provide the required organic carbon source for the metabolism of heterotrophic microorganisms, and the material filling layer The zero-valent iron released from the groundwater layer can consume dissolved oxygen in the groundwater environment through chemical reactions, providing a good anaerobic environment for heterotrophic microorganisms, which is conducive to the biodegradation of pollutants in groundwater by heterotrophic microorganisms, and the carbon dioxide produced by heterotrophic microorganisms can also Provide the inorganic carbon source required for metabolism of autotrophic microorganisms, two kinds of microorganisms can coexist without competition, heterotrophic microorganisms and autotrophic microorganisms participa...

Embodiment 2

[0053] The composite functional material used in the combined biochemical restoration of contaminated groundwater in this example is basically the same as in Example 1, except that the outer diameter of the composite functional material in this example is 0.9-1.5 cm, and the pore diameter is 10-300 μm. The distance between them is 50-400um. The composite functional material includes an inner core, a material filling layer and an outer shell; the particle size of the inner core is 3mm, and the material filling layer is composed of the following components in mass percentage: 33.3% of carbon-releasing raw material (soybean straw), plastic bonding raw material ( Attapulgite) 33.3%, reduced iron powder 6.7%, and natural binder 26.7%. The shell is composed of the following components by mass percentage: 48% of plastic bonding raw materials (12% for ordinary Portland cement, 36% for attapulgite), 12% for high permeability raw materials (8% for diatomite , fine quartz sand is 4%), t...

Embodiment 3

[0064] The composite functional material used in the combined biochemical restoration of contaminated groundwater in this example is basically the same as in Example 1, except that the outer diameter of the composite functional material in this example is 0.9-1.4 cm, and the pore diameter is 5-350 um. The distance between them is 10-300um. The composite functional material includes an inner core, a material filling layer and an outer shell; the particle size of the inner core is 4 mm, and the material filling layer is composed of the following components in mass percentage: 41.7% of carbon-releasing raw material (wheat straw), plastic bonding raw material ( Attapulgite) 25%, reduced iron powder 3.3%, natural binder 30%. The shell is composed of the following components by mass percentage: 26.6% of plastic bonding raw materials (13.3% for ordinary Portland cement, 13.3% for attapulgite), 40% for high permeability raw materials (diatomaceous earth), this Examples The pore diame...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com