Citric acid dehydrogenated calcium ascorbate and preparation method and application thereof

A technology of calcium ascorbate and ascorbic acid, which is applied in the field of biochemical medicine and food, can solve the problems of calcium citrate difficulty, usage restrictions, and difficult absorption by humans and animals, and achieve the effects of facilitating human body absorption, reducing costs, and good market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

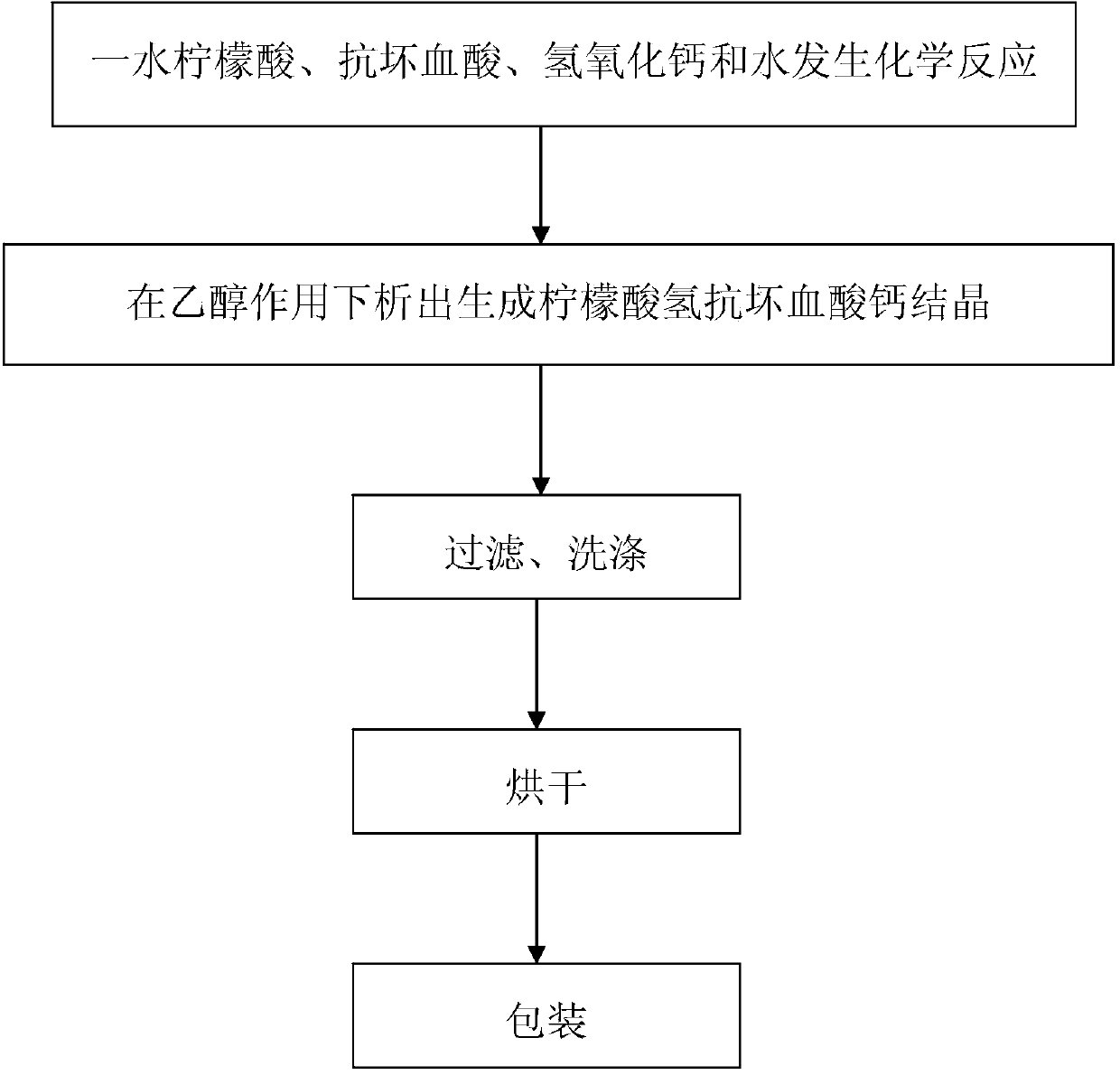

[0028] The preparation method flowchart of hydrogen citrate calcium ascorbate is as figure 1 shown.

[0029] The preparation method of hydrogen citrate calcium ascorbate of the present embodiment comprises the following steps:

[0030] (1) Weigh 420.28g of citric acid monohydrate, 176.13g of ascorbic acid, 222.24g of calcium hydroxide and a certain amount of water, and put the raw materials into the reaction kettle together;

[0031] (2) Start the chemical reaction for half an hour, the chemical reaction formula is:

[0032] 2(C 6 h 8 o 7 )·H 2 O+C 6 h 8 o 6 +3Ca(OH) 2 = Ca 3 H(C 6 h 7 o 6 )(C 6 h 5 o 7 ) 2 ·3H 2 O↓+5H 2 O, the reaction condition is normal temperature;

[0033] (3) Shut down for half an hour, add ethanol to make the chemical reaction mature, and precipitate calcium hydrogen citrate ascorbate crystals;

[0034] (4) Turn on the machine for half an hour, then filter and wash the materials in the reactor after the reaction, and release calcium...

Embodiment 2

[0037] The preparation method flowchart of hydrogen citrate calcium ascorbate is as figure 1 shown.

[0038] The preparation method of hydrogen citrate calcium ascorbate of the present embodiment comprises the following steps:

[0039] (1) Weigh 840.56g of citric acid monohydrate, 352.26g of ascorbic acid, 444.48g of calcium hydroxide and a certain amount of water, and put the raw materials into the reaction kettle together;

[0040] (2) Start the chemical reaction for half an hour, the chemical reaction formula is:

[0041] 2(C 6 h 8 o 7 )·H 2 O+C 6 h 8 o 6 +3Ca(OH) 2 = Ca 3 H(C 6 h 7 o 6 )(C 6 h 5 o 7 ) 2 ·3H 2 O↓+5H 2 O, the reaction condition is normal temperature;

[0042] (3) Shut down for half an hour, add ethanol to make the chemical reaction mature, and precipitate calcium hydrogen citrate ascorbate crystals;

[0043] (4) Turn on the machine for half an hour, then filter and wash the materials in the reactor after the reaction, and release calcium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com