Petroleum fracturing proppant and preparation method thereof

A fracturing proppant and oil technology, which is applied in chemical instruments and methods, earthwork drilling, and fluid production, etc., can solve the problems of few applications, difficult to reuse in large quantities, and no cost advantage, and can accelerate the crystalline phase reaction. time, the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-10

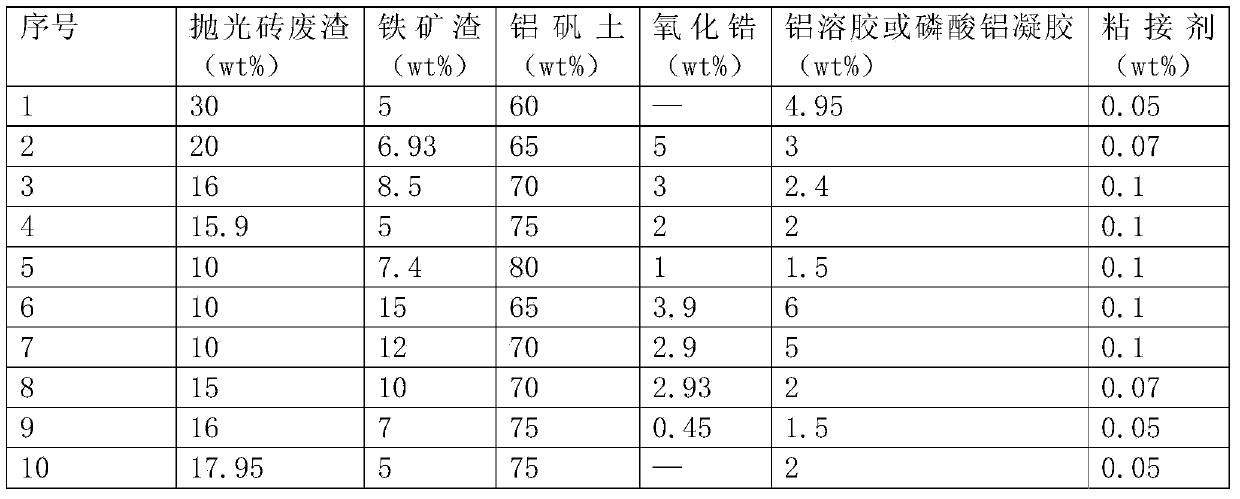

[0031] With reference to Table 1, Table 1 is the formulation table of Examples 1-10.

[0032] Table 1

[0033]

[0034] Weigh the raw materials according to the formula components given in Table 1, then add 40% to 70% of the dry weight of water for ball milling to make a slurry with a fineness of 350 to 600 mesh; then spray dry the slurry and pass The granulator performs rolling granulation to make granular powder; then the granular powder is dried and sieved to obtain granular powder with a particle size of 20 mesh to 60 mesh (850 to 250 μm). Select 2.5 meters * 45 meters rotary kiln, calcining at 1100 DEG C ~ 1180 DEG C for 1-3 hours (the calcining time increases with the content of bauxite in the formula and lengthens, for example the calcining time of embodiment 1 is 1 hour, embodiment 1 The calcination time of 4 and 9 is 2.5 hours, and the calcination time of embodiment 5 is 3 hours.), to obtain the oil fracturing proppant. Its particle size is 20-60 mesh (850-250μm)...

Embodiment 11-12

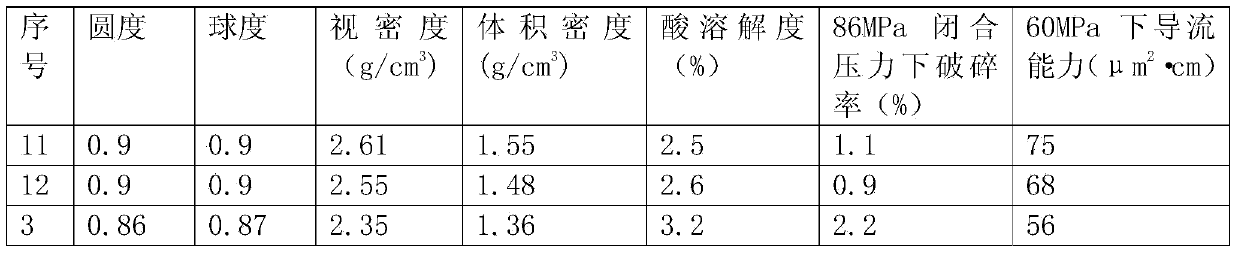

[0040] In addition, in order to improve the flow conductivity of the prepared oil fracturing proppant, the present invention also provides Example 11 and Example 12.

[0041] Select the petroleum fracturing proppant particles prepared in the above example 3, and use a 20-ton ball mill to charge 40 to 45 tons of material for self-grinding and polishing (self-grinding and polishing does not add ball milling media such as balls, and uses the material itself for polishing) After 3 to 4 hours, after the ball is out, sieve and remove the throwing debris below 60 meshes, and then wrap the polished particles with a resin layer, specifically, use a drum mixer to disturb the polished particle powder During the process, atomized resin is sprayed, and the temperature in the drum mixer is kept in the range of 80-100°C through the hot air source at the other end. Wherein the resin selected in embodiment 11 is phenolic resin, and the resin selected in embodiment 12 is epoxy resin. The forme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com