Moisture-containing solid material drying device using carrying balls to assist in drying and drying method

A solid material and drying device technology, applied in the direction of drying solid materials, drying solid materials without heating, progressive dryers, etc., can solve the problems of easy hardening, materials to be dried that cannot be turned, and difficult to dry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

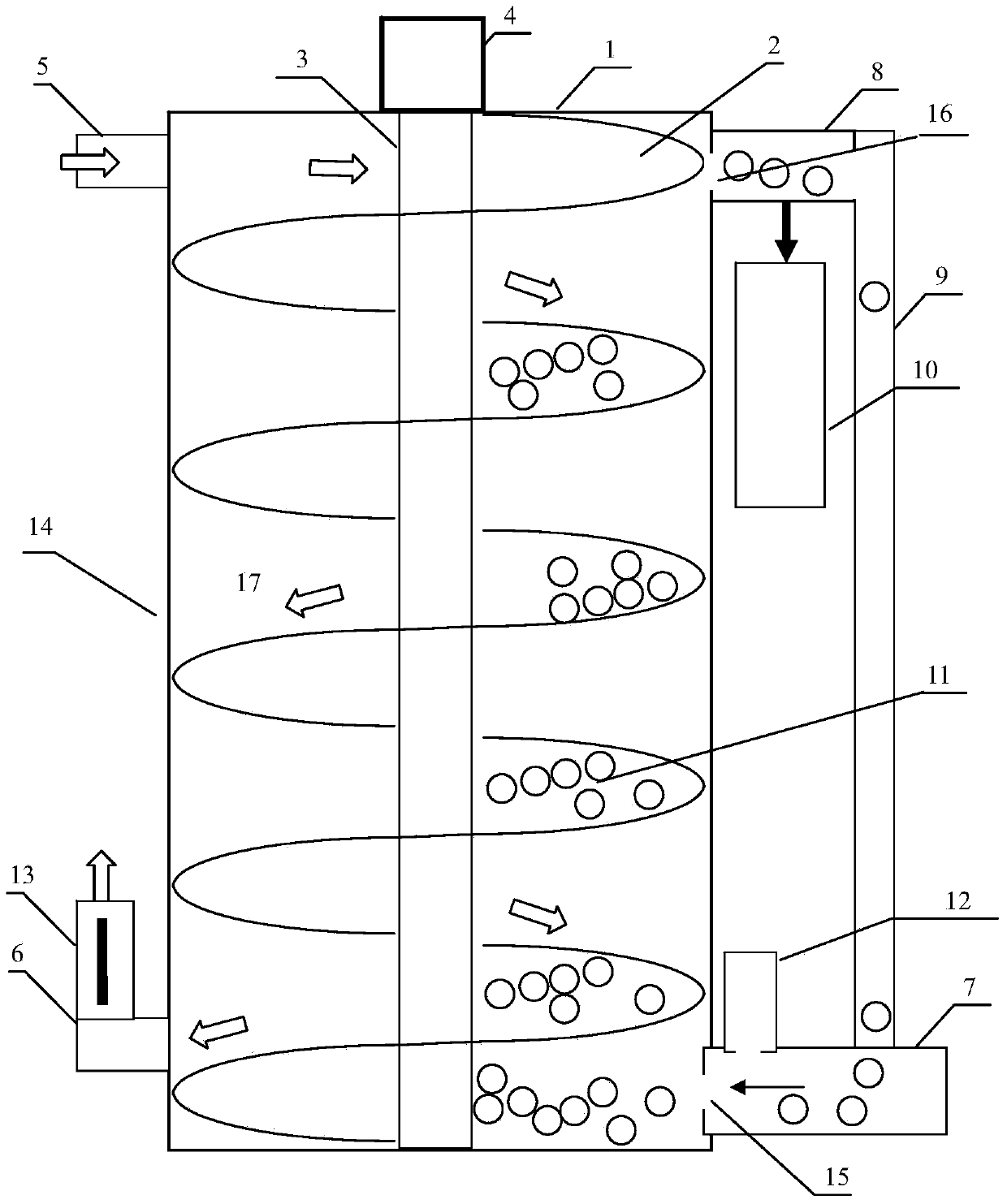

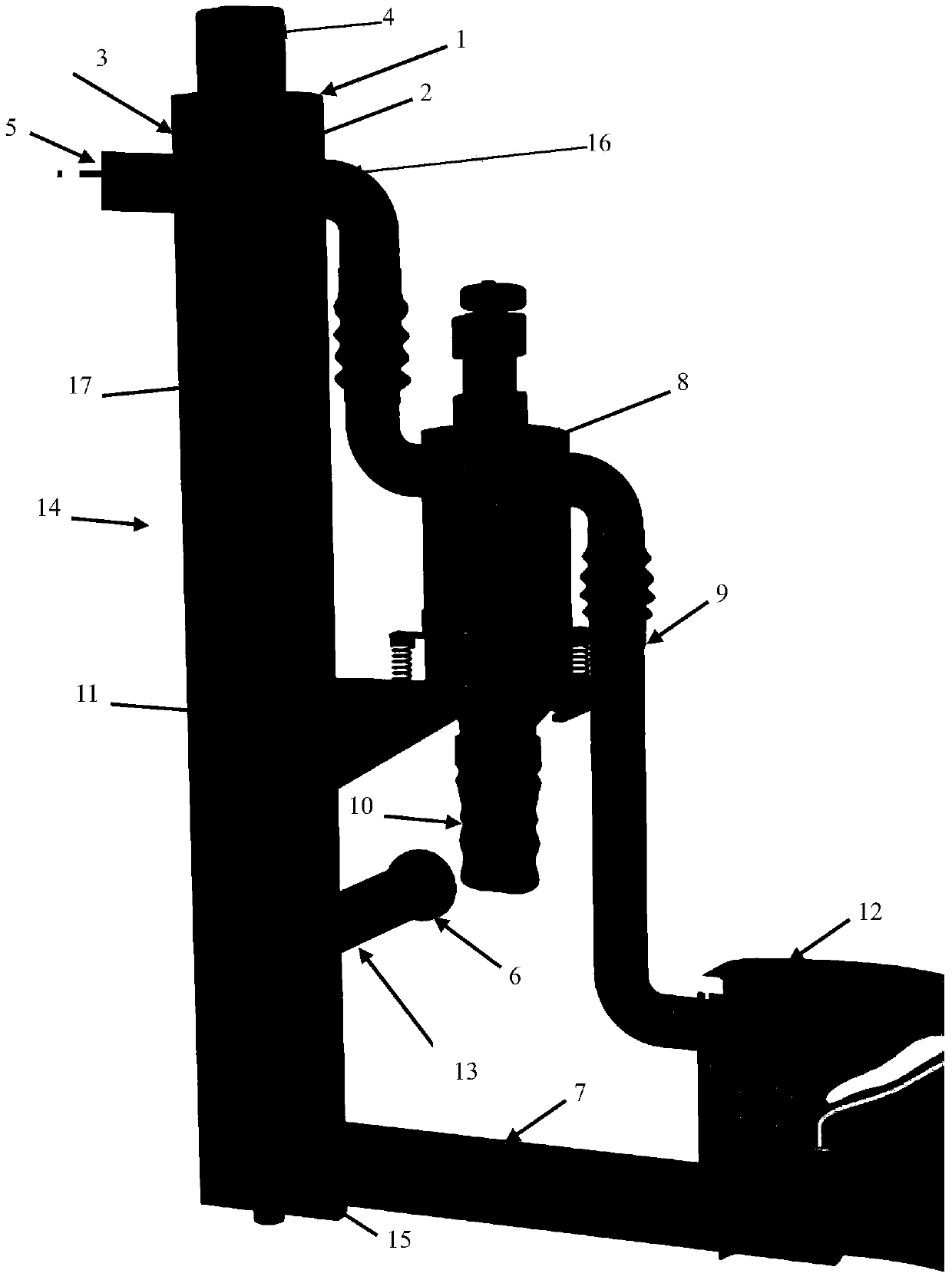

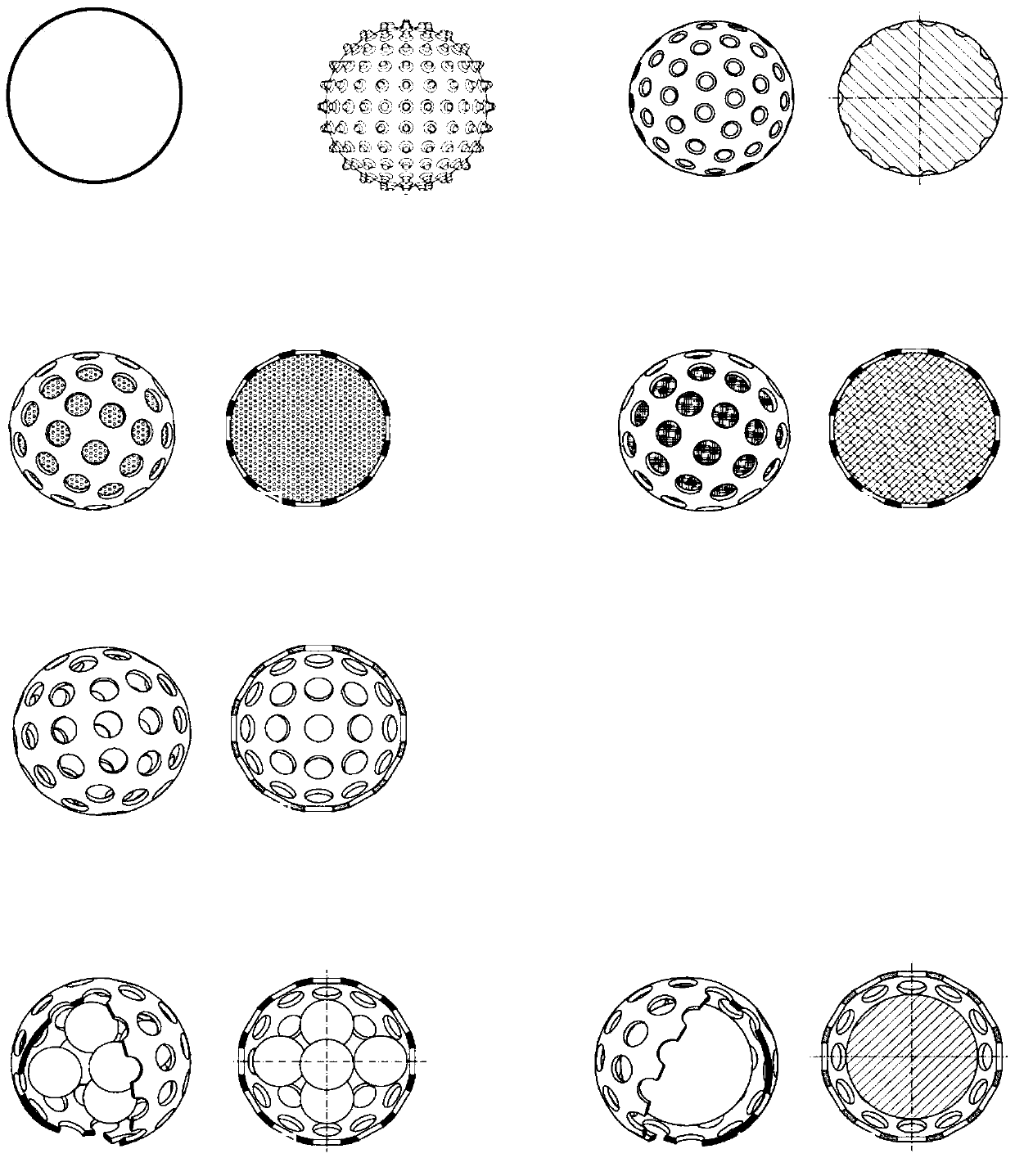

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1. Novel flush-free toilet

[0045] The original intention of the present invention is to meet the requirements of the Bill & Melinda Gates Foundation to "create the next generation of sanitation facilities" and "reinvent the toilet plan", and to design a toilet that can "run away from the water supply pipeline and indeed kill pathogens; Recycling; low price and easy promotion" "next generation toilet". For the new type of toilet in this example see image 3 . where the reference signs and figure 1 The reference signs in have the same meaning. In this embodiment, the water-containing solid material is feces, and the feed port is a toilet or a squatting pan. Wherein feces refers to stool and / or urine. The feces are not limited to human feces, and may also be animal feces, such as animal feces from poultry farms.

[0046] The new toilet workflow is:

[0047] 1) A group of carrying balls 11 and the feces / urine mixture are stirred and mixed in the agitator...

Embodiment 2

[0052] Example 2. Kitchen waste treatment device

[0053] Kitchen waste is a difficult part of domestic waste. It has a high content of organic matter, breeds bacteria, produces peculiar smell, and is mixed with other recyclable waste, which increases the difficulty of subsequent sorting and treatment.

[0054] Utilize application example 1 of the present invention, and feed port 12 wherein is connected to a pulverizer, kitchen waste-leftovers etc. are pulverized as water-containing solid material to be dried and mixed with carrier balls, and the rest are processed The steps are the same as in Example 1, and then the kitchen waste can be dried and converted into sterilized organic fertilizers.

Embodiment 3

[0055] Embodiment 3. the processing of all the other water-containing solid materials

[0056] Obviously, the water-containing solid materials to be dried are not limited to feces and kitchen waste, but can also be livestock waste from farms, sludge from sewage treatment tanks, lake sludge, waste residue from the food fermentation industry, and Chinese herbal medicines after extracting active ingredients. Waste slag, etc., all can utilize device and method of the present invention to handle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com