Multi-stage micro-nano structural material, preparation method thereof, battery containing multi-stage micro-nano structural material

A nano-micron and micro-sheet technology, applied in the field of advanced inorganic nanomaterials, can solve problems such as high synthesis temperature, environmental hazards, and poor crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

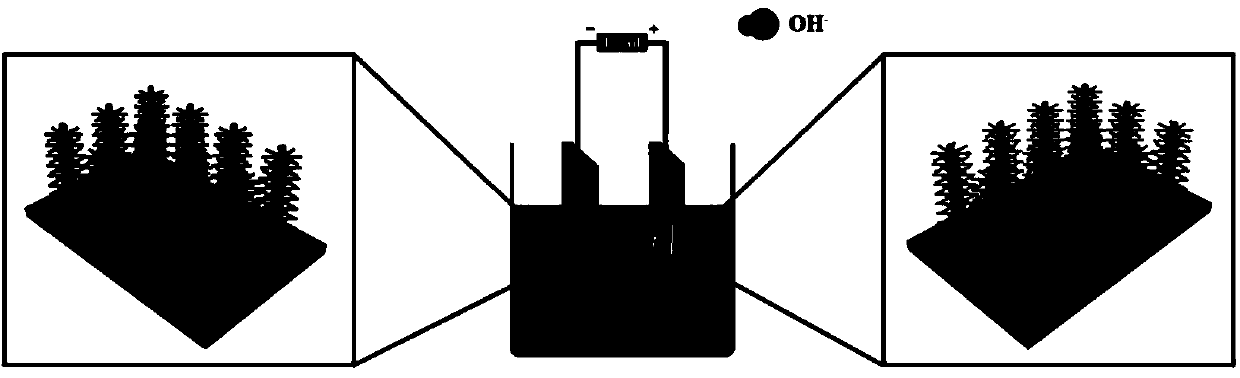

Method used

Image

Examples

Embodiment 1

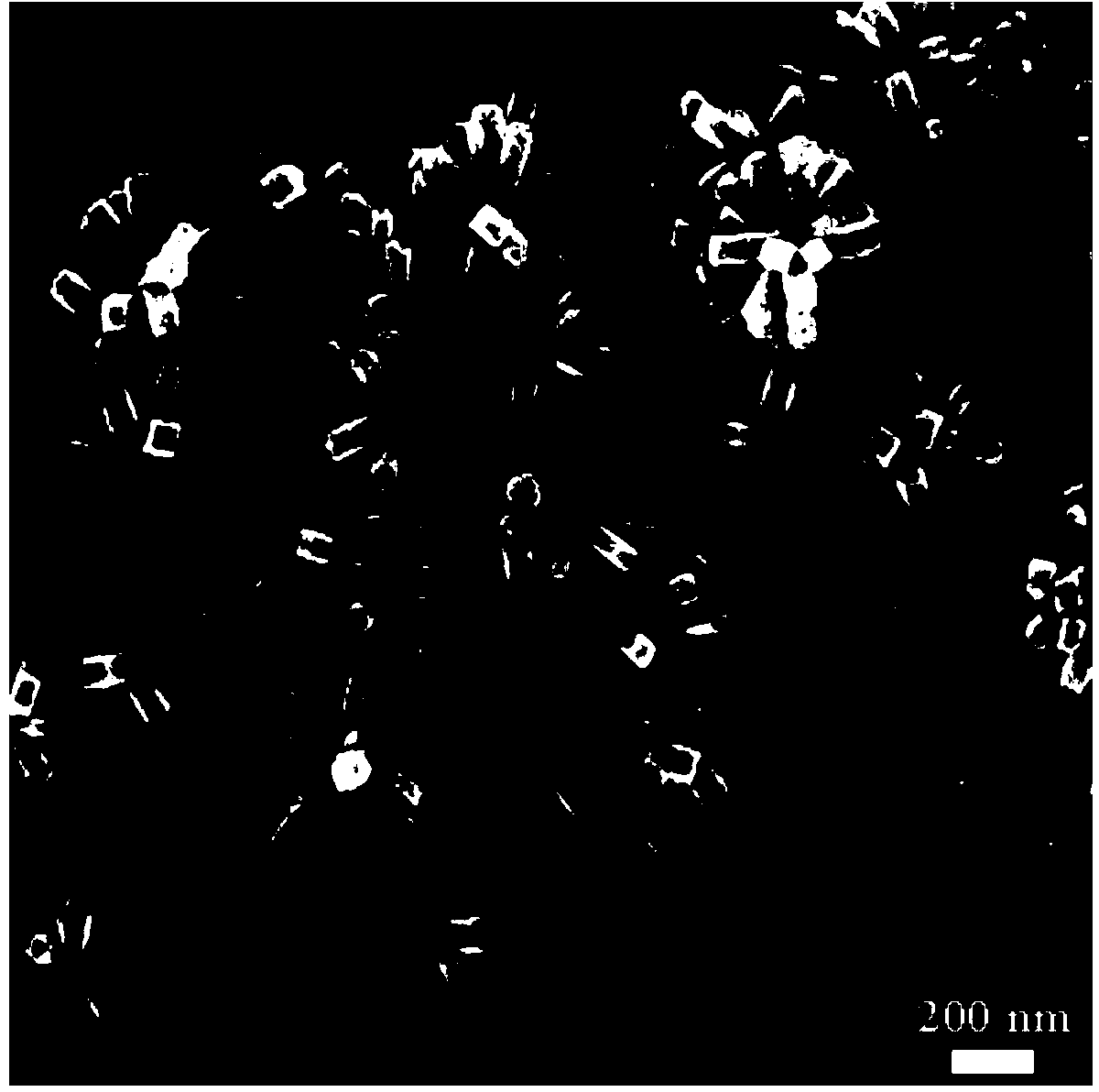

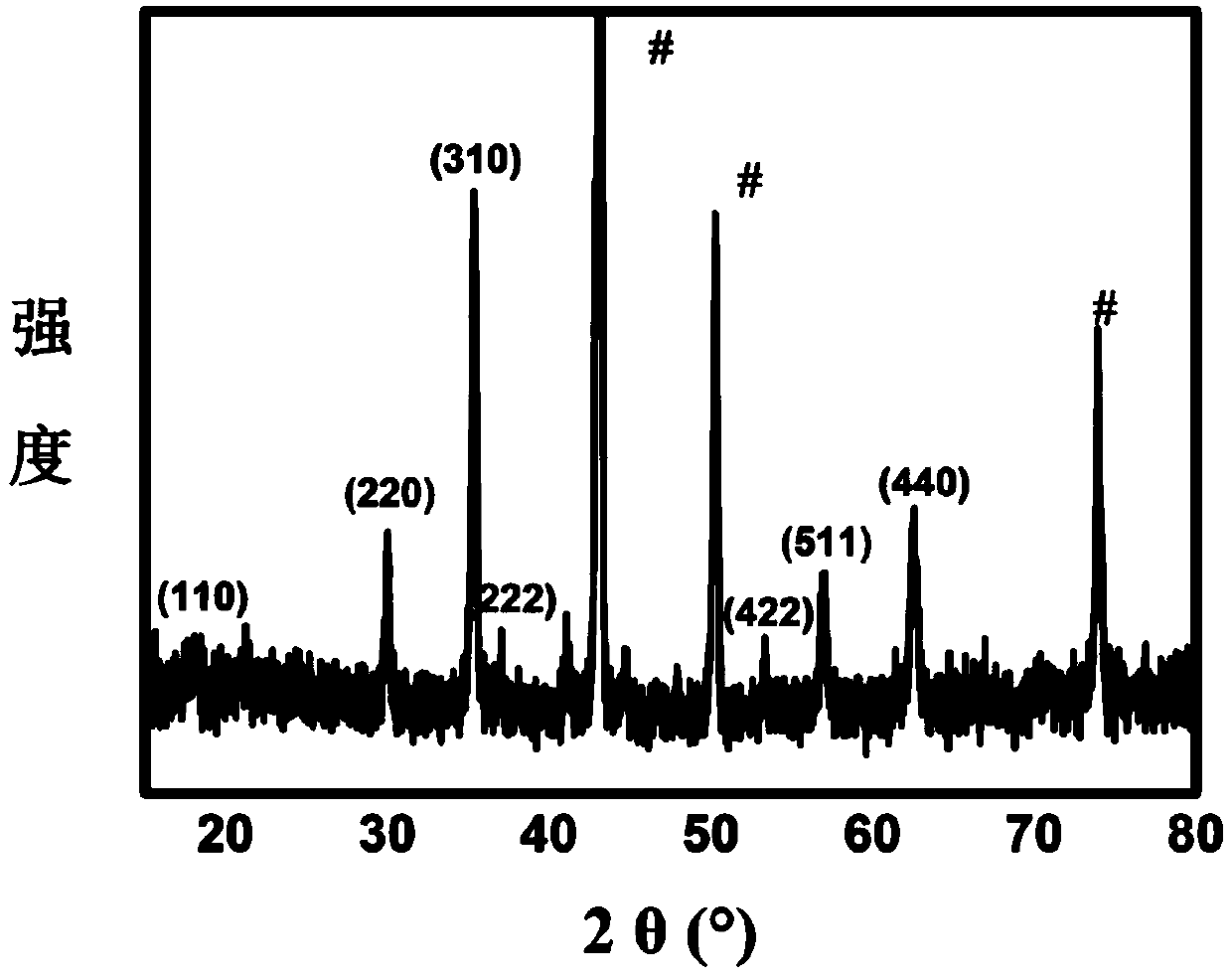

[0066] a. put the foamed copper substrate into the first reactor at an angle, then add cobalt nitrate comprising 0.05 mol / liter, the first ammonium fluoride of 0.2 mol / liter and urea of 0.25 mol / liter to the reactor Aqueous solution, then close the reaction kettle, raise the temperature to 120°C and keep it under autogenous pressure for 12 hours to carry out the first hydrothermal reaction, so as to grow cobalt hydroxide primary microrod arrays on the surface of the copper foam substrate perpendicular to the substrate;

[0067] b. Take out the copper foam substrate, wash and dry;

[0068] c. put the foamed copper substrate treated in step b into the second reactor, and then add ferric nitrate containing 0.075 mol / liter, 0.2 mol / liter of ammonium fluoride and 0.25 mol / liter to the reaction kettle The second aqueous solution of urea, seal the reaction kettle, raise the temperature to 100 ° C and keep it under autogenous pressure for 6 hours to carry out the second hydrothermal...

Embodiment 2

[0073] Referring to the method in Example 1, the temperature in step a of Example 1 is changed to 100° C., and the time is changed to 6 hours.

[0074] Its scanning electron microscope picture is shown in the appendix Figure 6 , its XRD spectrum is shown in the appendix Figure 7 , and its cyclic voltammetry curve is shown in the appendix Figure 8 , and its cycle stability diagram is shown in the appendix Figure 9 .

Embodiment 3

[0076] Referring to the method in Example 1, the copper foam substrate is replaced with a nickel foam substrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com