Method for preparing hierarchical bimetallic composite oxide denitrification catalyst

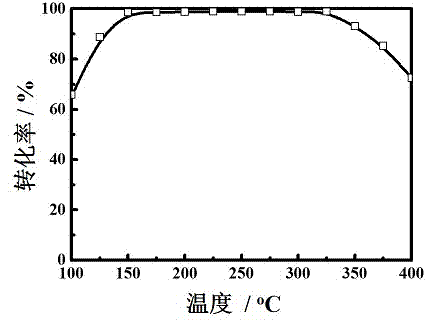

A composite oxide and denitrification catalyst technology, which is applied in the field of hierarchical structure bimetallic composite oxide denitration catalyst and its preparation, can solve the problems of poor catalytic mass transfer, lower specific surface, and influence on the catalytic performance of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

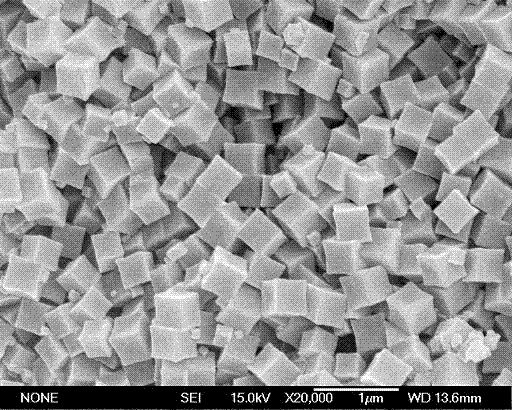

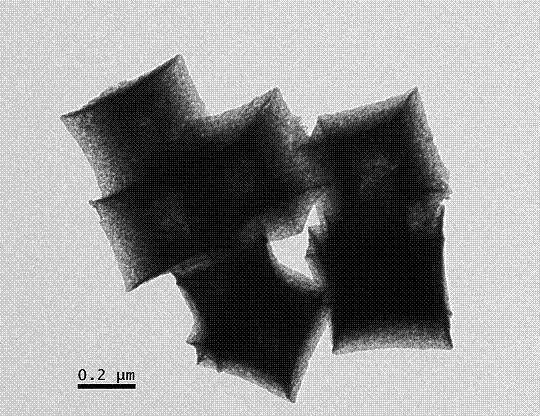

[0017] Dissolving polyvinylpyrrolidone and manganese acetate in a molar ratio of 1:0.1 in a mixed solvent of deionized water and ethanol with a volume ratio of 1:3, stirring to obtain a clear solution A with a metal salt concentration of 0.01 mol / L; A certain amount of potassium cobaltcyanide was dissolved in deionized water to obtain a clear solution B with a concentration of 0.01 mol / L; then, under stirring conditions at room temperature, an equal volume of solution B was slowly dropped into solution A, and continued to stir after the dropwise addition 15 min; after aging at room temperature for 24 h, filter, wash with deionized water and ethanol three times, collect the precipitate, and then dry at room temperature for 12 h to obtain Mn 3 [Co(CN) 6 ] 2 ·nH 2 O precursor. Will Mn 3 [Co(CN) 6 ] 2 ·nH 2 The O precursor is placed in a tube furnace, with 1 o C / min heating rate to 450 o C, keep warm for 2 hours, and finally cool naturally to room temperature with the fur...

Embodiment 2

[0020] Dissolving polyvinylpyrrolidone and manganese acetate in a molar ratio of 1:0.5 in a mixed solvent of deionized water and ethanol with a volume ratio of 1:0.1, stirring to obtain a clear solution A with a metal salt concentration of 0.1 mol / L; A certain amount of potassium cobaltcyanide was dissolved in deionized water to obtain a clear solution B with a concentration of 0.1 mol / L; then at 60 o Under the condition of stirring in C, slowly drop an equal volume of solution B into solution A, and continue stirring for 15 min after the addition; 60 o C was aged for 48 h, filtered, washed three times with deionized water and ethanol, and the precipitate was collected, then dried at room temperature for 12 h to obtain Mn 3 [Co(CN) 6 ] 2 ·nH 2 O precursor. Will Mn 3 [Co(CN) 6 ] 2 ·nH 2 The O precursor was placed in a tube furnace, with 3 o C / min heating rate to 500 o C, keep warm for 4 hours, and finally cool naturally to room temperature with the furnace to obtain...

Embodiment 3

[0023] Dissolving polyvinylpyrrolidone and manganese acetate in a molar ratio of 1:1 in a mixed solvent of deionized water and ethanol with a volume ratio of 1:10, stirring to obtain a clear solution A with a metal salt concentration of 0.05 mol / L; A certain amount of potassium cobaltcyanide was dissolved in deionized water to obtain a clear solution B of 0.05 mol / L; then at 40 o Under the condition of stirring in C, slowly drop an equal volume of solution B into solution A, and continue stirring for 15 min after the addition; 40 o After standing and aging for 48 h, C was filtered, washed three times with deionized water and ethanol, and the precipitate was collected, then dried at room temperature for 12 hours to obtain Mn 3 [Co(CN) 6 ] 2 ·nH 2 O precursor. Will Mn 3 [Co(CN) 6 ] 2 ·nH 2 The O precursor was placed in a tube furnace at 0.05 o C / min heating rate to 600 o C, keeping it warm for 3 hours, and finally cooling down to room temperature naturally with the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com