Composite metal plate process

A metal composite board and process technology, applied in layered products, lamination devices, lamination, etc., can solve the problem of large differences in thermal conductivity and thermal expansion coefficient, can not guarantee the flatness of metal composite boards, and does not meet the requirements of flocking metal strips Process requirements and other issues, to achieve significant energy-saving effects, process simplification, energy-saving improvement, and strong promotional effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

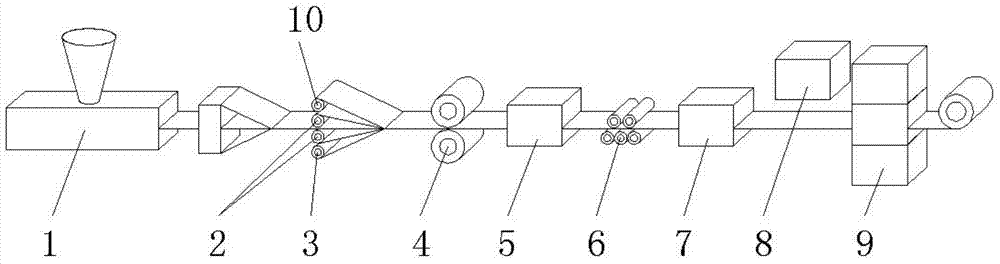

[0027] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 :

[0028] A metal composite panel process, comprising the following steps,

[0029] ① Preparation of plastic core material: inject plastic granule raw material into the extruder for plasticization treatment to obtain plastic hot melt, and extrude plastic hot melt to form plastic core material;

[0030] ②Co-extrusion of plastic core material and metal strip: plastic core material and upper and lower metal strips are co-extruded, and the inner sides of the upper and lower metal strips are covered with film by a compound machine, and the compound machine composites the upper and lower metal strips respectively On both sides of the plastic core material, the plastic film is melted by the waste heat of the plastic core material, and the plastic core material and the upper and lower metal strips are bonded together to obtain a metal composit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com