Coupled Fenton oxidation and anaerobic digestion reactor for treating surplus sludge

A technology of excess sludge and anaerobic digestion, used in sludge treatment, biological sludge treatment, water/sludge/sewage treatment, etc., to achieve uniform distribution, improve treatment effect and efficiency of chemical use, and increase sludge digestion. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

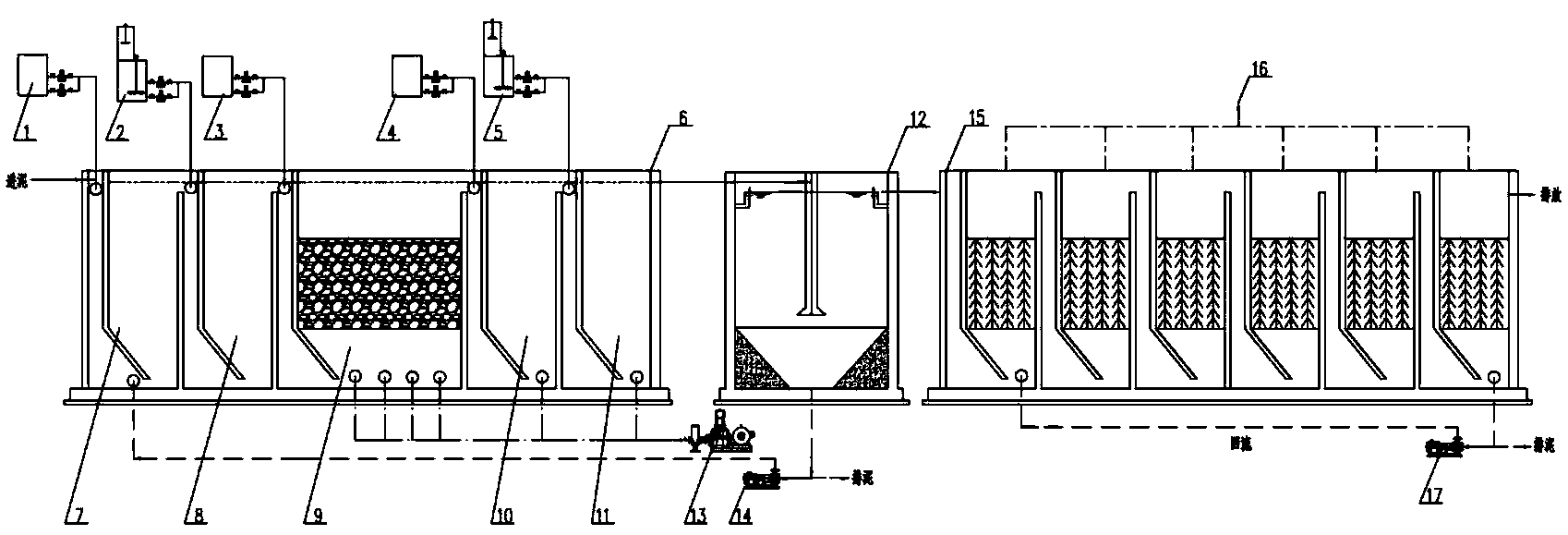

[0044] A reaction device coupled with Fenton oxidation and anaerobic digestion is used to treat excess sludge with a sludge concentration of 4g / L. The device includes the following process steps:

[0045] 1. The remaining sludge to be treated is pumped into the acid adding tank with a pump. Turn on the acid adding device 1, add nitric acid to the front end of the acid adding pool 7, adjust the pH to be controlled at about 3.0, use the ferrous adding device 2 to add ferrous nitrate 450mg / L to the ferrous pool 8, and enter it at the entrance of the Fenton main reaction pool 9 end, through the H 2 o 2 Dosing device 3 adds 3750mg / L H 2 o 2 , and reacted in Fenton main reaction tank 9 for 45 minutes. After the reaction is complete, it enters the alkali adding tank 10, and uses the alkali adding device 4 to add NaOH to adjust the pH to 9.0. After adding PAM to the front end of the PAM adding tank 11 for flocculation, it flows into the sedimentation tank 12.

[0046] 2. The iron...

Embodiment 2

[0050] A reaction device coupled with Fenton oxidation and anaerobic digestion is used to treat excess sludge with a sludge concentration of 8g / L. The method includes the following process steps:

[0051] 1. The remaining sludge to be treated is pumped into the acid adding tank with a pump. Turn on the acid adding device 1, add nitric acid to the front end of the acid adding pool 7, adjust the pH to about 3.5, use the ferrous adding device 2 to add ferrous nitrate 900mg / L to the ferrous adding pool 8, and enter the Fenton main reaction pool 9 end, add 7500mg / L H through H2O2 dosing device 3 2 o 2 , and reacted in Fenton main reaction tank 9 for 60 minutes. After the reaction is complete, it enters the alkali-adding tank 10, and uses the alkali-adding device 4 to add NaOH to adjust the pH to 9.5. After adding PAM to the front section of the PAM-adding tank 11 for flocculation, it flows into the sedimentation tank 12.

[0052] 2. The iron-containing sludge at the bottom of th...

Embodiment 3

[0056] A reaction device coupled with Fenton oxidation and anaerobic digestion is used to treat excess sludge with a sludge concentration of 12g / L. The method includes the following process steps:

[0057] 1. The remaining sludge to be treated is pumped into the acid adding tank with a pump. Turn on the acid adding device 1, add nitric acid to the front end of the acid adding pool 7, adjust the pH to about 4.0, use the ferrous adding device 2 to add ferrous nitrate 1350mg / L to the ferrous adding pool 8, and enter it at the entrance of the Fenton main reaction pool 9 At the end, add 11250mg / LH2O2 through the H2O2 dosing device 3, and react in the Fenton main reaction tank 9 for 90min. After the reaction is complete, it enters the alkali-adding tank 10, and uses the alkali-adding device 4 to add NaOH to adjust the pH to 8.5. After adding PAM to the front section of the PAM-adding tank 11 for flocculation, it flows into the sedimentation tank 12.

[0058] 2. The iron-containing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com