Artificial ecological stone slab for decoration and preparation method thereof

A production method and ecological technology, which is applied in the field of artificial ecological stone slabs and its preparation, can solve the problems of high hazards of volatile organic compounds, complex artificial stone process, and high energy consumption, and achieve high resistance to freeze-thaw cycles and improve resource utilization Efficiency, environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Step 1, providing a mold, and coating a release agent on the inner surface of the mold.

[0063] Step 2, prepare slurry:

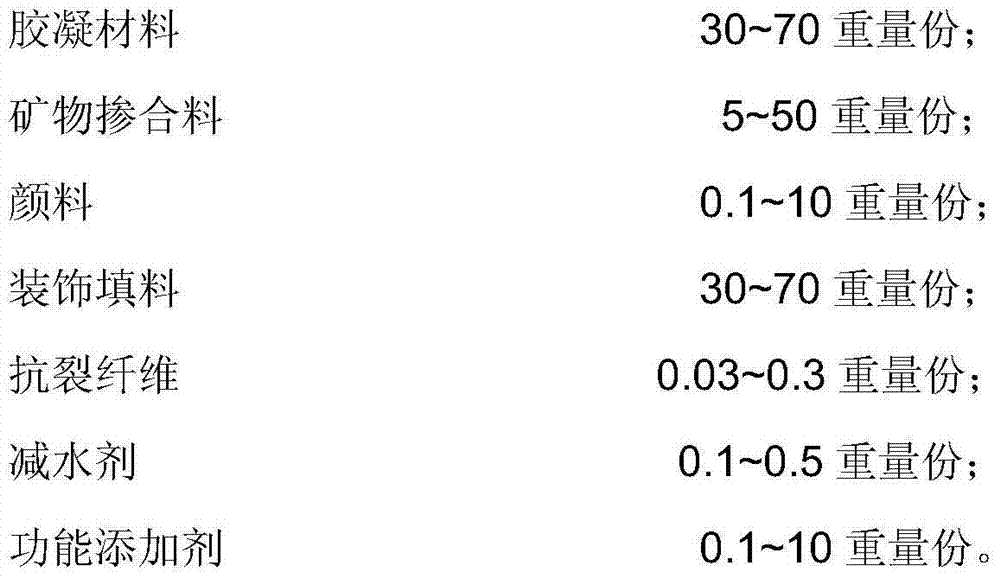

[0064] The surface layer includes a batter layer, and the formula components of the batter layer include:

[0065]

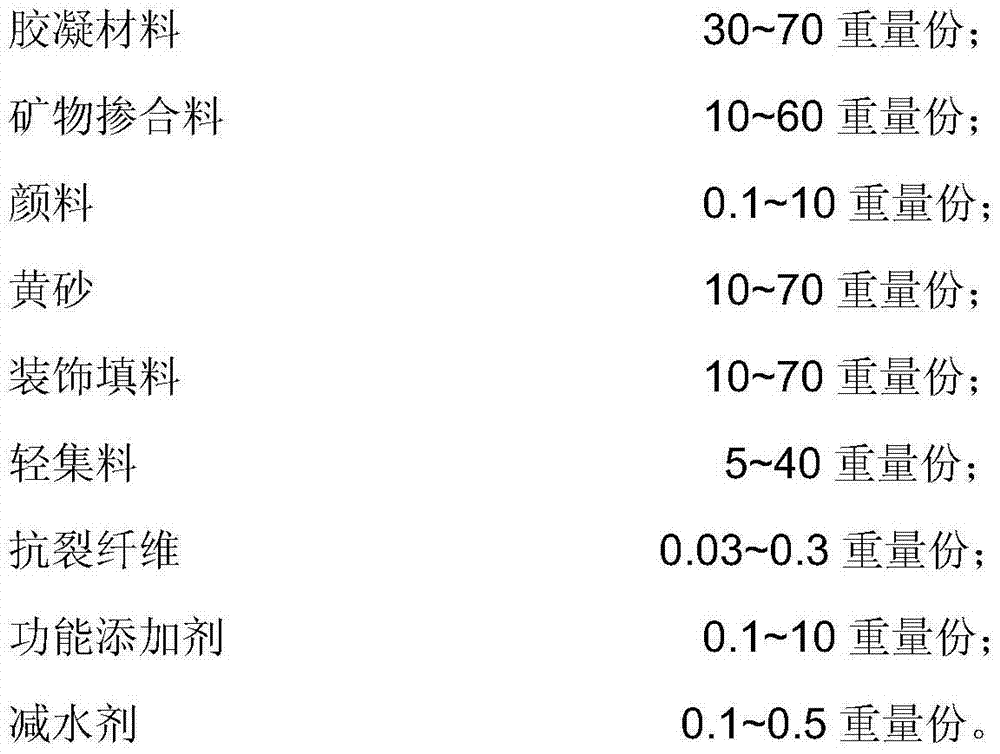

[0066] The underlying formulation components include:

[0067]

[0068] In step 3, the slurry of the surface layer and the bottom layer are respectively stirred evenly.

[0069] Step 4, pouring the prepared surface layer slurry into the mould.

[0070] Step 5, laying the pre-cut grid cloth on the formed surface layer slurry.

[0071] Step 6: Pouring the prepared bottom layer slurry on the surface layer on which the grid cloth is laid, and then vibrating or pressing to form.

[0072] Step 7, curing at 40°C for 18 hours.

[0073] Step 8, take off the mold, and then use a sandblasting machine to treat the surface, and use high-pressure gas to dry the surface dust, which is the finished product.

Embodiment 2

[0075] Step 1, providing a mold, and coating a release agent on the inner surface of the mold.

[0076] Step 2, prepare slurry:

[0077] The surface layer includes a batter layer, and the formula components of the batter layer include:

[0078]

[0079] The underlying formulation components include:

[0080]

[0081] In step 3, the slurry of the surface layer and the bottom layer are respectively stirred evenly.

[0082] Step 4, pouring the prepared surface layer slurry into the mould.

[0083] Step 5, laying the pre-cut grid cloth on the formed surface layer slurry.

[0084] Step 6: Pouring the prepared bottom layer slurry on the surface layer on which the grid cloth is laid, and then vibrating or pressing to form.

[0085] Step 7, curing at 40°C for 24 hours.

[0086] Step 8, take off the mold, use a grinder to grind the surface with water, and the finished product will be finished after the surface moisture is dried.

Embodiment 3

[0088] Step 1, providing a mold, and coating a release agent on the inner surface of the mold.

[0089] Step 2, prepare slurry:

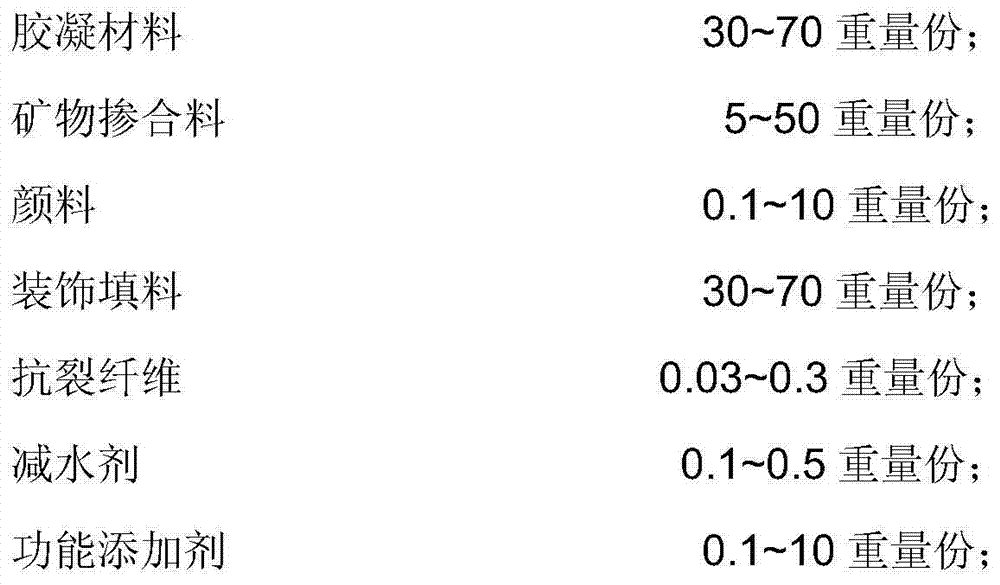

[0090] The surface layer includes a batter layer, and the formula components of the batter layer include:

[0091]

[0092] The underlying formulation components include:

[0093]

[0094] In step 3, the slurry of the surface layer and the bottom layer are respectively stirred evenly.

[0095] Step 4, pouring the prepared slurry of the surface layer into the mold for molding.

[0096] Step 5, laying the pre-cut grid cloth on the formed surface layer slurry.

[0097] Step 6: pour the prepared bottom layer slurry on the surface layer on which the grid cloth is laid, and then vibrate or press to form.

[0098] Step 7, curing at 40°C for 24 hours.

[0099] In step 8, the mold is removed, and the surface is subjected to water grinding and polishing with a grinder, and the finished product is obtained. Example 4

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com