Synthetic method of dihydrogen geranyl acetone and dihydrogen nicky acetone

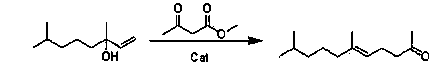

A technology of dihydrogeranyl acetone and dihydrofarnesyl acetone, which is applied in the field of Carroll reaction, can solve problems not involving the synthesis method of dihydrogeranyl acetone or dihydrofarnesyl acetone, and reduce the Production cost, high efficiency, effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

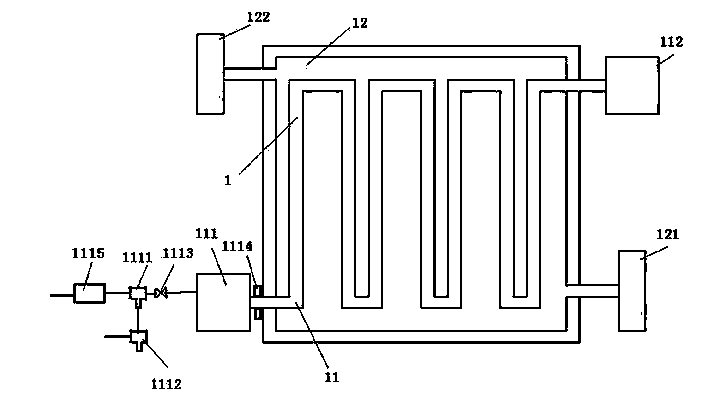

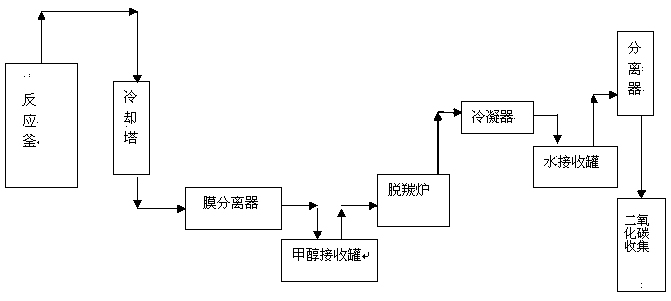

[0051] Synthesis of dihydrogeranylacetone: 5000L stainless steel reaction kettle, add 1000kg of dihydrolinalool, add 30kg of aluminum isopropoxide as a catalyst, add 770kg of methyl acetoacetate dropwise at about 180°C, and complete the dropwise addition in about 2.5 hours After adding methyl acetoacetate dropwise, continue the heat preservation reaction for about 2 hours. As the reaction progresses, carbon dioxide and methanol gas continue to overflow from the reaction system, pass through the cooling tower and film cooler, and enter the gas-liquid separator to separate a large amount of methanol , carbon dioxide gas carries a small amount of acetone and low-boiling substances into the decarbonylation furnace for combustion and then converts carbon dioxide and water. The carbon dioxide gas with a purity of more than 99% is separated through the separator, and then enters the alkynylation station through the gas guide pipe to adjust the pH value of the water phase. . The end p...

Embodiment 2

[0060] Synthesis of dihydrofarnesylacetone: 5000L stainless steel reaction kettle, add 1000kg of tertiary nerolidol, add 27 kg of aluminum isopropoxide as catalyst, add 540kg of methyl acetoacetate dropwise at about 180°C, drop for about 2.5 hours After the addition is completed, add the methyl acetoacetate dropwise and continue the heat preservation reaction for about 2 hours. As the reaction progresses, carbon dioxide and methanol gas continuously overflow from the reaction system, pass through the cooling tower and film cooler, and enter the gas-liquid separator to separate a large amount of Methanol, carbon dioxide gas with a small amount of acetone and low-boiling substances enters the decarbonylation furnace for combustion and converts carbon dioxide and water. The carbon dioxide gas with a purity of more than 99% is separated through a separator, and then enters the alkynylation station through the gas guide pipe to adjust the water phase. pH value. The end point of the...

Embodiment 3

[0066] The synthetic method of dihydrogeranyl acetone comprises steps:

[0067] (1) Ingredients: Weigh 800 parts of dihydrolinalool, 25 parts of aluminum isopropoxide, and 700 parts of methyl acetoacetate by weight, and set aside;

[0068] (2) Synthesis: Mix all the dihydrolinalool and aluminum isopropoxide, raise the temperature to 160°C and start to add methyl acetoacetate dropwise, after the dropwise addition, continue to keep warm for 1.5h to synthesize dihydrogeranylacetone;

[0069] (3) Recovery of by-products: Cool and separate the carbon dioxide and methanol gas generated during the reaction, recover the methanol liquid generated by cooling, and introduce the carbon dioxide gas entrained with methanol gas and low-boiling organic impurity gas into the decarbonylation furnace, of which methanol Gas and low-boiling organic impurity gas are fully burned in the decarbonylation furnace to generate carbon dioxide and water vapor. The mixed gas is then separated and converted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com