Preparation method of cellulose-based super absorbent resin having yellowing inhibiting function

A technology of water-absorbent resin and cellulose, which is applied in the field of biomass material preparation, can solve unseen problems, achieve the effects of inhibiting yellowing, prolonging storage time and performance, important applications and economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

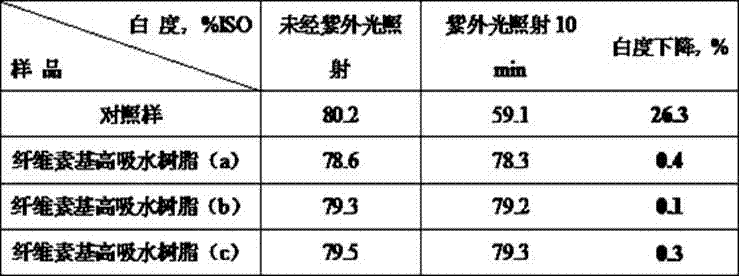

Examples

Embodiment 1

[0016] 1) Add the waste cotton yarn into the mixed solution of sodium hydroxide and urea that was precooled at 4°C for 30 min. The concentration of sodium hydroxide is 6 wt%, the concentration of urea is 14 wt%, and the mass ratio of waste cotton yarn to waste cotton yarn is 20:1, and stir evenly , freeze at -20°C for 1 h, and mechanically stir to obtain a uniform and transparent waste cotton yarn cellulose solution;

[0017] 2) The waste cotton yarn cellulose solution obtained in step 1) was passed through nitrogen for 20 min, and an initiator was added at 40 °C for 10 min, and the mass ratio of ammonium persulfate to waste cotton yarn was 0.4:1. Add a stabilizer, the mass ratio of 2,6-di-tert-butyl-4-methylphenol to waste cotton yarn is 0.005:1, the mass ratio of ultraviolet absorber UV-9 to waste cotton yarn is 0.001:1, and the mass ratio of acrylamide to waste cotton yarn The ratio is 1:1; the mass ratio of acrylic acid to waste cotton yarn is 1:1, and the mass ratio of so...

Embodiment 2

[0019] 1) Add cotton linters to a mixed solution of sodium hydroxide and urea that was precooled at 4°C for 30 min. The concentration of sodium hydroxide was 6 wt%, the concentration of urea was 14 wt%, and the mass ratio of cotton linters was 30:1. Stir evenly, freeze at -20°C for 2 h, and stir mechanically to obtain a uniform and transparent linter cellulose solution;

[0020] 2) The cotton linter cellulose solution obtained in step 1) was passed through nitrogen for 20 minutes, and an initiator was added at 50°C for 15 minutes of initiation. The mass ratio of ammonium persulfate to cotton linters was 0.3:1. Add a stabilizer, the mass ratio of 2,6-di-tert-butyl-4-methylphenol to cotton linters is 0.02:1, the mass ratio of ultraviolet absorber UV-9 to cotton linters is 0.005:1, and the mass ratio of acrylamide to cotton linters The mass ratio of linters is 2:1; the mass ratio of acrylic acid to cotton linters is 3:1, the mass ratio of sodium hydroxide to acrylic acid is neutr...

Embodiment 3

[0022] 1) Add cotton linters to the mixed solution of sodium hydroxide and urea precooled at 4°C for 30 min. The concentration of sodium hydroxide is 6 wt%, the concentration of urea is 14 wt%, and the mass ratio of cotton linters is 40:1. Stir evenly, freeze at -20°C for 1.5 h, and mechanically stir to obtain a uniform and transparent linter cellulose solution;

[0023] 2) The cotton linter cellulose solution obtained in step 1) was passed through nitrogen for 20 min, and an initiator was added at 60 °C for 5 min, and the mass ratio of ammonium persulfate to cotton linters was 0.5:1. Add a stabilizer, the mass ratio of 2,6-di-tert-butyl-4-methylphenol to cotton linters is 0.05:1, the mass ratio of ultraviolet absorber UV-9 to cotton linters is 0.01:1, and the mass ratio of acrylamide to cotton linters The mass ratio of linters is 3:1; the mass ratio of acrylic acid to cotton linters is 6:1, the mass ratio of sodium hydroxide to acrylic acid is neutralized with sodium hydroxid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com