Preparation method of quantum-dot phosphorescent imprinted polymer

A technology for imprinting polymers and quantum dots, which is applied in fluorescence/phosphorescence, material excitation analysis, etc., can solve the problems of lack of universality and selectivity, low sensitivity, slow speed, etc., and achieve good optical stability, sensitivity and selection sex enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

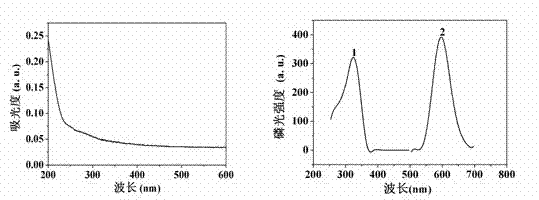

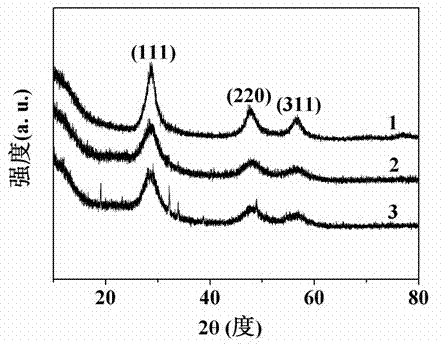

[0030] In a 100 mL three-neck flask, add 1.797 g ZnSO 4 ·7H 2 O, 0.059 g MnCl 2 4H 2 O, 20 mL of distilled water, the resulting mixed solution was stirred at room temperature for 15 min under nitrogen, then 5 mL of 1.501 g Na 2 S·9H 2 O aqueous solution, stirred for 15 min, and finally 5 mL of ethanol solution containing 37.7 μL MPTS was added to the mixed solution and continued to stir for 18 hours. The obtained MPTS-modified Mn-doped ZnS quantum dots were centrifuged, washed three times with distilled water and absolute ethanol, and dried in a vacuum oven.

[0031] In a 50 mL flask, add 10 mL of anhydrous ethanol solution containing 100 mg 2,4,5-trichlorophenol and 181 μL APTS and stir for 30 min. Add 0.9 mL TEOS (crosslinking monomer) to the resulting mixture and stir for 5 min. Then 300 mg of MPTS-modified Mn-ZnS quantum dots and 1.8 mL of 6% ammonia water were added to the mixture and stirred for 16 h. Mn-ZnSMPTSMIPs were obtained by centrifugation, and washed ...

Embodiment 2

[0033] In a 100 mL three-neck flask, add 1.797 g ZnSO 4 ·7H 2 O, 0.118 g MnCl 2 4H 2 O, 20 mL of distilled water, the resulting mixed solution was stirred at room temperature for 30 min under nitrogen, then added 5 mL containing 1.501 g Na 2 S·9H 2 O aqueous solution, stirred for 30 min, and finally 5 mL of ethanol solution containing 75.5 μL MPTS was added to the mixed solution and continued to stir for 24 hours. The obtained MPTS-modified Mn-doped ZnS quantum dots were centrifuged, washed three times with distilled water and absolute ethanol, and dried in a vacuum oven.

[0034] In a 50 mL flask, add 10 mL of anhydrous ethanol solution containing 100 mg 2,4,5-trichlorophenol and 362 μL APTS and stir for 30 min. Add 2.26 mL of TEOS (crosslinking monomer) to the resulting mixture and stir for 15 min. Then 500 mg of MPTS-modified Mn-ZnS quantum dots and 6.78 mL of 6% ammonia water were added to the mixture and stirred for 20 h. Mn-ZnSMPTSMIPs were obtained by centrif...

Embodiment 3

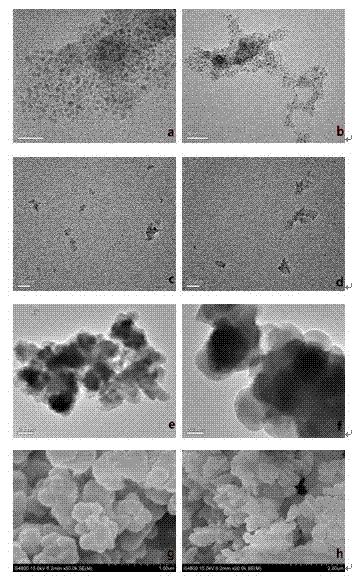

[0036] In a 100 mL three-neck flask, add 1.797 g ZnSO 4 ·7H 2 O, 0.1 g MnCl 2 4H 2 O, 20 mL of distilled water, the resulting mixed solution was stirred at room temperature for 20 min under nitrogen, then 5 mL of 1.501 g Na 2 S·9H 2 O aqueous solution, stirred for 20 min, and finally 5 mL of ethanol solution containing 60 μL MPTS was added to the mixed solution and continued to stir for 20 h. The obtained MPTS-modified Mn-doped ZnS quantum dots were centrifuged, washed three times with distilled water and absolute ethanol, and dried in a vacuum oven. Such as figure 2 (c, d) As shown, MPTS successfully modified ZnS quantum dots.

[0037] In a 50 mL flask, add 10 mL of anhydrous ethanol solution containing 100 mg 2,4,5-trichlorophenol and 250 μL APTS and stir for 30 min. Add 1 mL of TEOS (crosslinking monomer) to the resulting mixture and stir for 10 min. Then 400 mg of MPTS-modified Mn-ZnS quantum dots and 2.5 mL of 6% ammonia water were added to the mixture and st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com