High-temperature-oxidation-resistant coating for electronic product and preparation method thereof

A high-temperature oxidation-resistant, electronic product technology, applied in the direction of coating, etc., can solve the problems that affect the appearance of metal, lack of protection, anti-rust and anti-static, etc., and achieve the effect of good protection of metal, small particles, and not easy to precipitate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

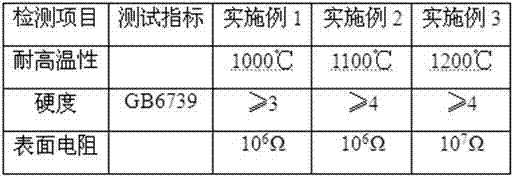

Embodiment 1

[0009] This embodiment provides a high-temperature oxidation-resistant coating for electronic products, which contains the following components in parts by mass: 68 parts of nano-titanium dioxide, 20 parts of aluminum oxide, 7 parts of sodium nitrite, 3 parts of magnesium oxide, 10 parts of feldspar powder, 10.5 parts of cooked high alumina powder, 1.5 parts of ferrous oxide, 7 parts of ceramic micropowder, 0.23 parts of spinel, 5 parts of liquid sodium silicate, 3 parts of water, 12 parts of paint antistatic agent.

[0010] The preparation steps of a high-temperature oxidation-resistant coating for electronic products are as follows: put nano-titanium dioxide, aluminum oxide, sodium nitrite, magnesium oxide, feldspar powder, cooked high-alumina powder, ferrous oxide and liquid sodium silicate into the kiln For melting, raise the temperature from 900°C to 1500°C within 4 hours, then cool to room temperature, add ceramic micropowder, spinel and water after crushing, add coating ...

Embodiment 2

[0012] This embodiment provides a high-temperature oxidation-resistant coating for electronic products, which contains the following components in parts by mass: 50 parts of nano-titanium dioxide, 8 parts of aluminum oxide, 3 parts of sodium nitrite, 1.2 parts of magnesium oxide, 5 parts of feldspar powder, 5 parts of cooked high alumina powder, 0.6 part of ferrous oxide, 3 parts of ceramic micropowder, 0.1 part of spinel, 2 parts of liquid sodium silicate, 1 part of water, 5 parts of paint antistatic agent.

[0013] The preparation steps of a high-temperature oxidation-resistant coating for electronic products are as follows: put nano-titanium dioxide, aluminum oxide, sodium nitrite, magnesium oxide, feldspar powder, cooked high-alumina powder, ferrous oxide and liquid sodium silicate into the kiln For melting, raise the temperature from 900°C to 1500°C within 4 hours, then cool to room temperature, add ceramic micropowder, spinel and water after crushing, add coating antistat...

Embodiment 3

[0015] This embodiment provides a high-temperature oxidation-resistant coating for electronic products, which contains the following components in parts by mass: 59 parts of nano-titanium dioxide, 14 parts of aluminum oxide, 5 parts of sodium nitrite, 2.1 parts of magnesium oxide, 7.5 parts of feldspar powder, 7.5 parts of cooked high alumina powder, 1 part of ferrous oxide, 5 parts of ceramic micropowder, 0.16 part of spinel, 3.5 parts of liquid sodium silicate, 2 parts of water, 8.5 parts of paint antistatic agent.

[0016] The preparation steps of a high-temperature oxidation-resistant coating for electronic products are as follows: put nano-titanium dioxide, aluminum oxide, sodium nitrite, magnesium oxide, feldspar powder, cooked high-alumina powder, ferrous oxide and liquid sodium silicate into the kiln For melting, raise the temperature from 900°C to 1500°C within 4 hours, then cool to room temperature, add ceramic micropowder, spinel and water after crushing, add coating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com