Radiative heat loss cooling coating, preparation method and application thereof

A technology of radiation heat dissipation and coating, applied in the application field of heat radiation technology, can solve problems such as poor heat dissipation of LEDs, and achieve the effect of increasing the specific surface area and conductivity of heat dissipation, improving the radiation coefficient, and improving the effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

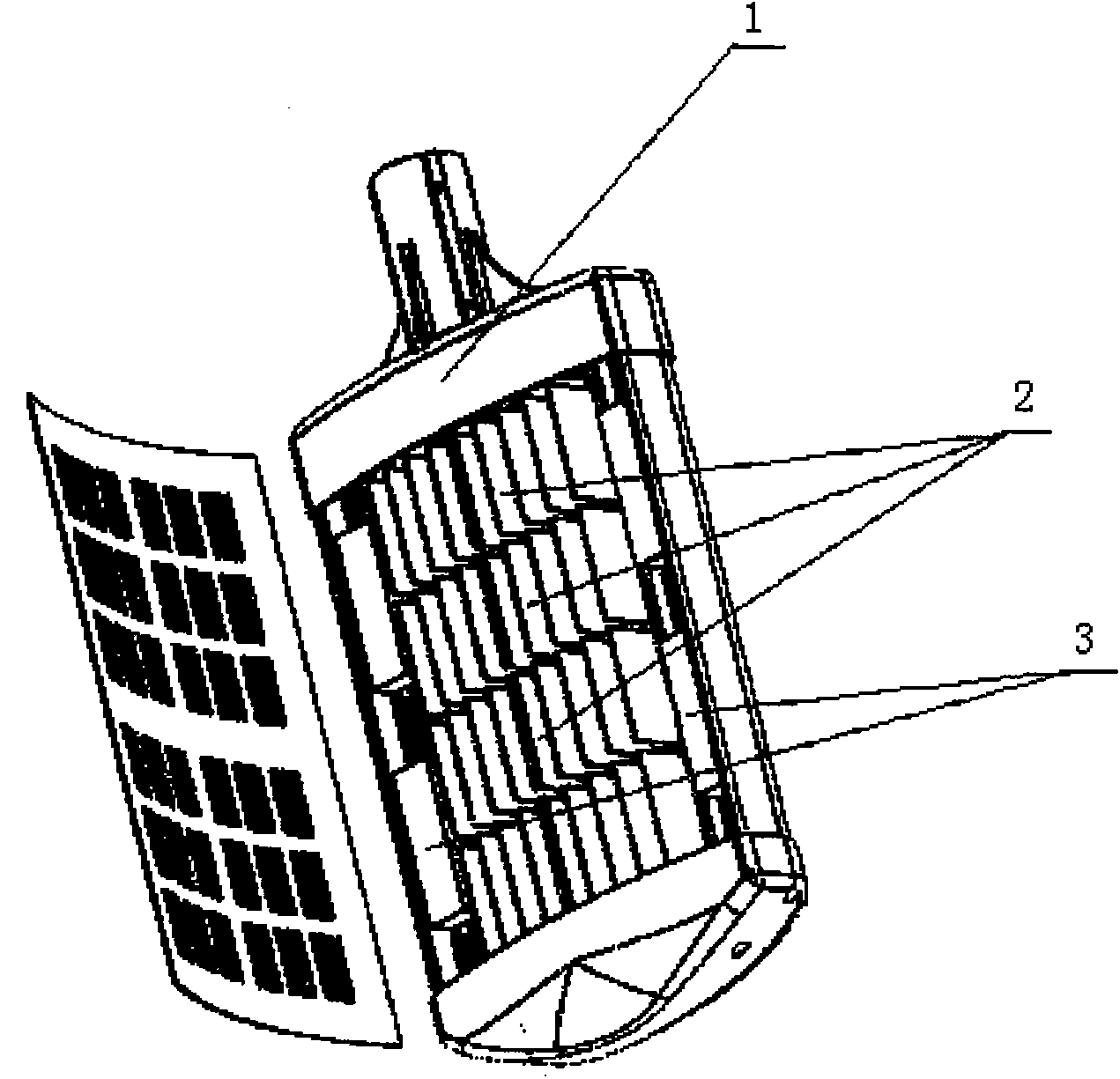

Image

Examples

Embodiment Construction

[0017] A radiative heat dissipation cooling coating, including A component, B component and filler, A component is the main coating, which is a solution formed by agglomeration of modified colloid particles treated at high temperature, and the particle size of the modified colloid particles is less than 100 nanometers, B component is ethylenediamine curing agent, the weight ratio of A component / B component is 9:1, and the filler is a material with high thermal conductivity and infrared emission, such as carbon nanotube or spinel Stone metal oxides.

[0018] The preparation method of the radiation cooling coating of the present invention is obtained by adding fillers to component A and mixing them uniformly, then slowly adding component B to component A, stirring slowly mechanically, and standing for 30 minutes. use.

[0019] The above-mentioned radiation cooling coating can be applied to LED lamps to improve the LED cooling effect in the form of infrared radiation. The specif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com