Thermal conductive resin composition

A technology of resin composition and thermal conductivity, which is applied in the field of thermal conductive resin composition to achieve the effect of suppressing warpage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0107] Synthesis examples, examples, and comparative examples are shown below to specifically describe the present invention, but the present invention is not limited by the following examples. In addition, the test regarding the effect related to this invention was performed as follows.

[0108] [viscosity]

[0109] The absolute viscosity of the oil and fat composition was measured at 25° C. using a Malcom viscometer (PC-1T type).

[0110] [Thermal conductivity]

[0111] Each composition was wrapped in a kitchen wrap, and measured with TPA-501 manufactured by Kyoto Denshi Kogyo Co., Ltd.

[0112] [hardness]

[0113] The composition was cured at 150° C. for 60 minutes, and measured with a Durometer A-type hardness meter manufactured by Shimadzu Corporation.

[0114] [softening temperature]

[0115] Cure the composition for 60 minutes at 150°C with TMA / SDTA841 from METTLER TOLEDO e Determination.

[0116] [Warpage test]

[0117] Each composition was sandwiched between a...

Synthetic example 1

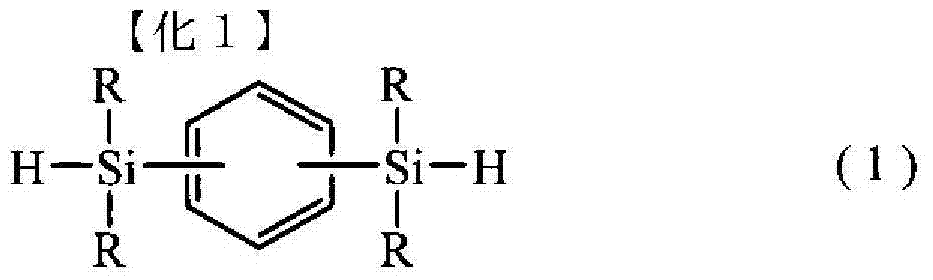

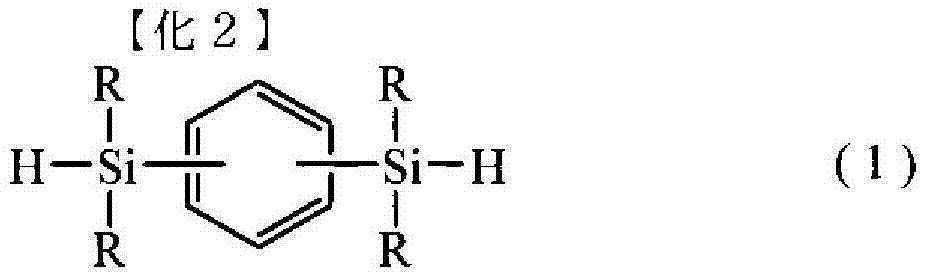

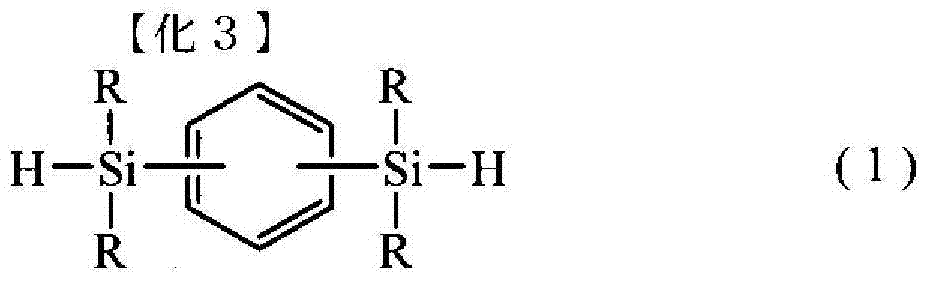

[0120] [Synthesis Example 1] Preparation of Component (A)

[0121] Vinyl norbornene (trade name: V0062, manufactured by Tokyo Chemical Industry Co., Ltd.; 5-vinylbicyclo[2.2.1] Hept-2-ene and approximately equimolar isomer mixture of 6-vinylbicyclo[2.2.1]hept-2-ene) 1,785 g (14.88 moles) and toluene 455 g, using an oil bath, heated to 85°C . 3.6 g of carbon powder supporting 5% by mass of platinum metal was added thereto, and 1,4-bis(dimethylsilyl)benzene 1,698 g (8.75 mol) was added dropwise over 180 minutes while stirring. After completion|finish of dripping, it cooled to room temperature after heating and stirring at 110 degreeC for 24 hours more. Then, the platinum metal-supported carbon was removed by filtration, and the toluene and excess vinylnorbornene were distilled off under reduced pressure to obtain 3,362 g of a colorless and transparent oily reaction product (viscosity at 25° C.: 12,820 mPa·s). Using FT-IR, NMR, GPC, etc. to analyze the results of the reaction ...

Embodiment 1~6、 comparative example 1~5

[0148] (A) - (F) components were mixed as follows, and the compositions of Examples 1-6 and Comparative Examples 1-5 were obtained.

[0149] That is, Components (A), (B) and (E) were added to 5 L Planetarium Mikisa (manufactured by Inoue Seisakusho Co., Ltd.) in the amounts shown in Tables 1 and 2, and mixed at room temperature for 1 hour. Next, add (C), (D), and (F) components, and mix uniformly. The measurement results of the viscosity, thermal conductivity, hardness, and softening temperature of the obtained composition and the results of the warpage test are shown in Tables 1 and 2 together.

[0150] 【Table 1】

[0151]

[0152] H / Vi=(the total number of hydrogen atoms bonded to silicon atoms in the component (C)) / (the total number of addition-reactive carbon-carbon double bonds in the component (A))

[0153] 【Table 2】

[0154]

[0155] H / Vi=(the total number of hydrogen atoms bonded to silicon atoms in the component (C)) / (the total number of addition-reactive carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com