Liquid slag granulation and waste heat dry process fluidization high-grade cascaded recycling method and liquid slag granulation and waste heat dry process fluidization high-grade cascaded recycling system

A cascade recovery, liquid slag technology, applied in the direction of recycling technology, heat exchanger types, lighting and heating equipment, etc., can solve the problems of not really realizing industrialization, the waste heat resources are not utilized, and stay, and improve the utilization of waste heat. The effect of grade and utilization efficiency, improving the utilization level of industrial waste heat, and good promotion and application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

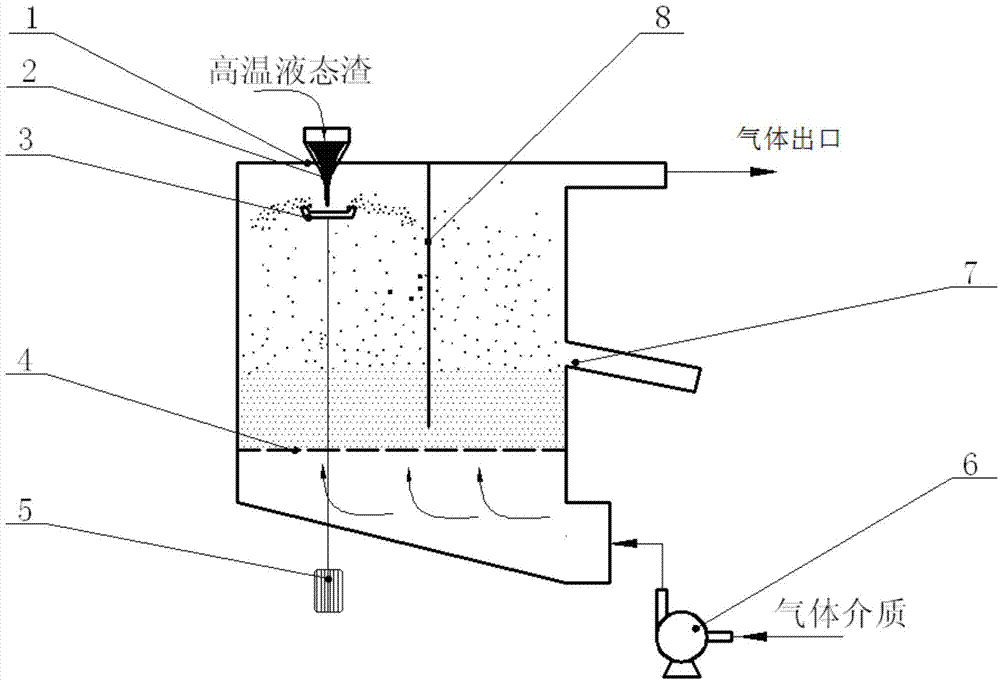

[0043] see figure 1 As shown, a high-grade cascade recovery method for liquid slag granulation and residual heat dry fluidization, including a fluidized bed 1, a high-temperature liquid slag inlet 2, a granulation device 3, an air distribution plate 4, a motor 5, and a fan 6 , Slag particle outlet 7 and dividing plate 8.

[0044] The process flow of high-temperature liquid slag is as follows: the fluidized bed 1 is divided into two connected chambers by a partition plate 8, a liquid slag inlet 2 is opened on one of the chambers, and at least one slag inlet 2 is opened on the other chamber. The high-temperature liquid slag flows into the granulation device 3 in the fluidized bed 1 from the high-temperature liquid slag inlet 2. The motor 5 is connected with the granulation device 3. The granulation device 3 can be a rotating cup. Under the action, the liquid slag is broken and granulated into particles, and the slag particles are fluidized and flow to the slag particle outlet 7...

Embodiment example 2

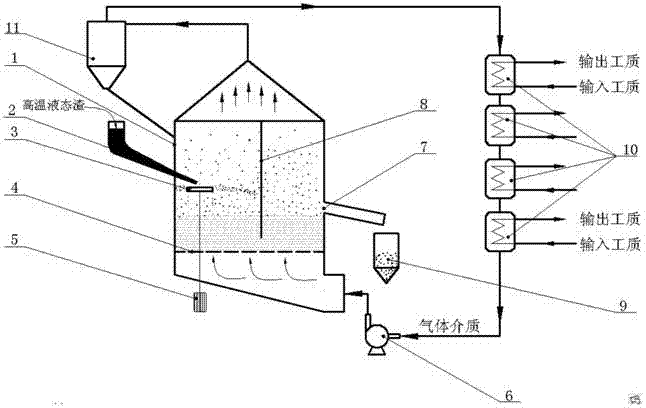

[0051] see figure 2 As shown, the process flow is similar to that of Example 1, the difference is that: (1) The inlet 2 of the high-temperature liquid slag in this example is arranged on the side of the fluidized bed 1 to guide the high-temperature liquid slag to flow obliquely into the fluidized bed; ( 2) The gas outlet is arranged on the top of the fluidized bed 1, and the high-temperature gas medium is discharged from the top of the fluidized bed 1, and a cyclone separator 11 is installed to separate the slag particles from the gas, and the separated slag particles flow back to the fluidized bed 1 for purification The final high-temperature gas transfers heat to other working fluids through several heat exchangers 10. (3) After the heat exchange by the heat exchanger 10, the temperature of the gas is lowered and then sent back to the fan 6 for reuse as the fluidized air circulation in the fluidized bed 1, so as to improve the utilization rate of waste heat.

Embodiment example 3

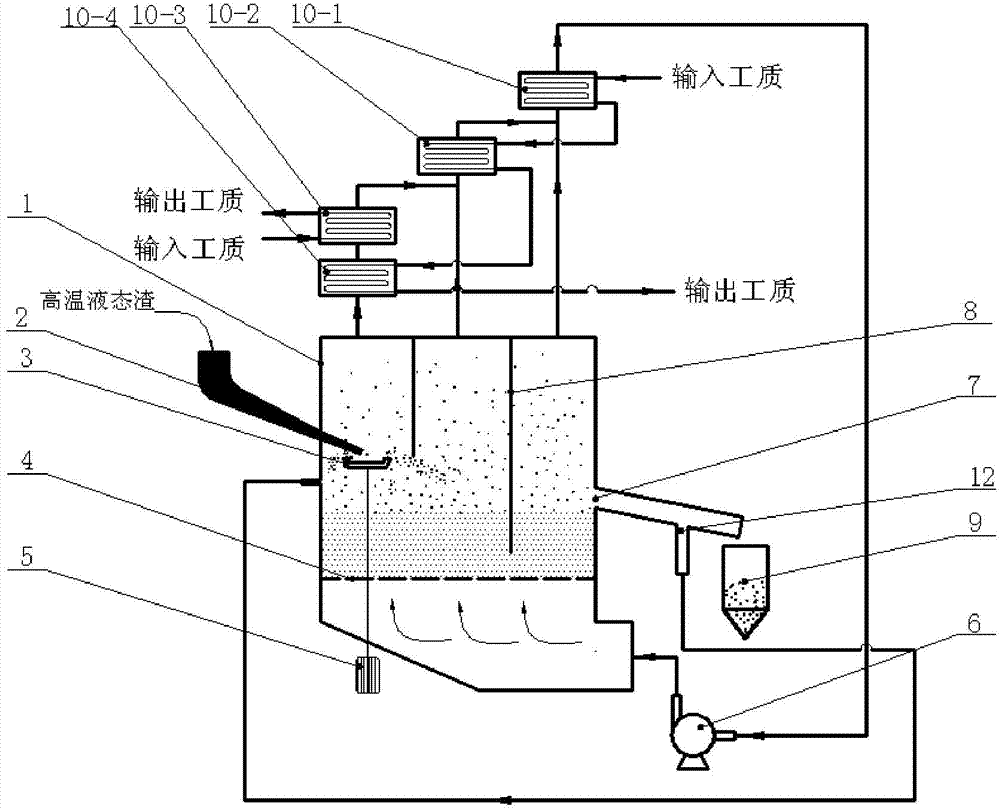

[0053] see image 3 As shown, the process flow is similar to that of Example 2, the difference is: (1) The fluidized bed 1 adopts a multi-chamber fluidized bed structure, and the bed of the fluidized bed 1 is divided into three by two partition plates. In the connected chambers, a high-temperature liquid slag granulation device 3 is installed in the first chamber, a liquid slag inlet 2 is opened in the first chamber, and a slag particle outlet 7 is arranged in the last chamber. (2) Each chamber of the fluidized bed 1 is provided with a gas outlet respectively, and the high-temperature gas after heat exchange with the high-temperature slag particles flows out from the gas outlet of each chamber, instead of mixing gases of different temperatures in each chamber as in the second embodiment . (3) According to the different temperatures of the gas outlets of each chamber, the superheater 10-4, the reheater 10-3, the evaporator 10-2 and the economizer 10-1 are respectively set up t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com