Method for strengthening surface of laser-clad titanium alloy

A laser cladding and surface strengthening technology is applied in the field of laser cladding titanium alloy surface strengthening of Ni-based composite coatings. The effect of small thermal expansion mismatch, reducing thermal stress and eliminating porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

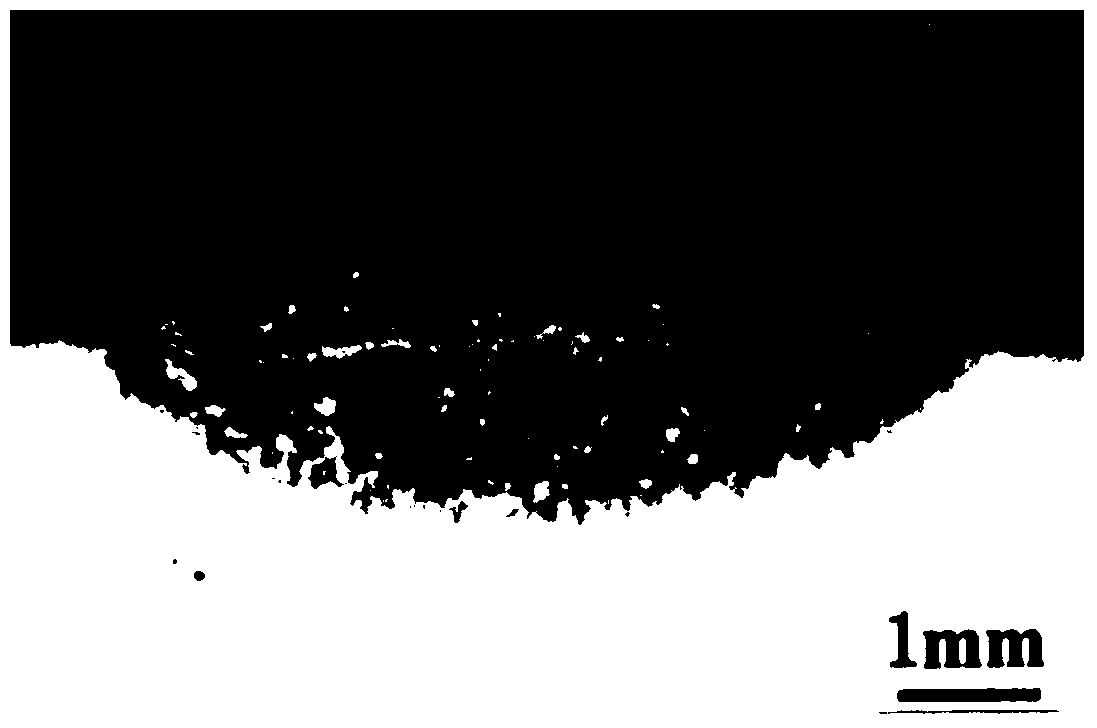

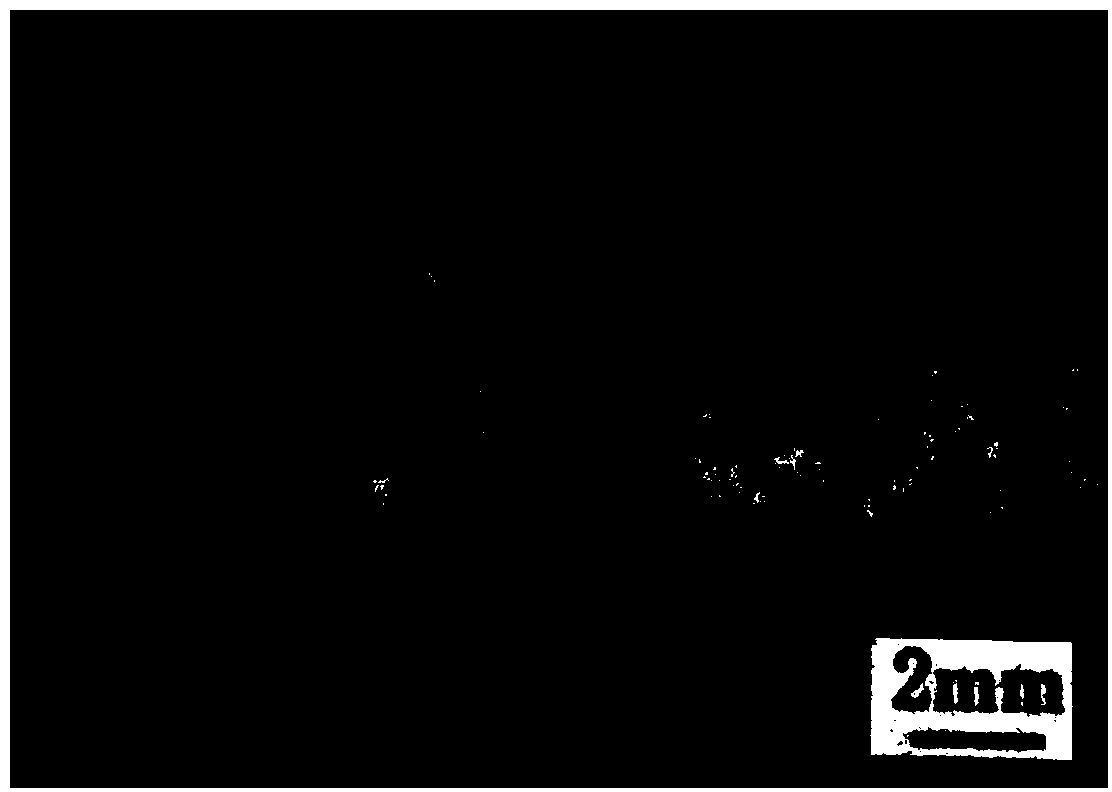

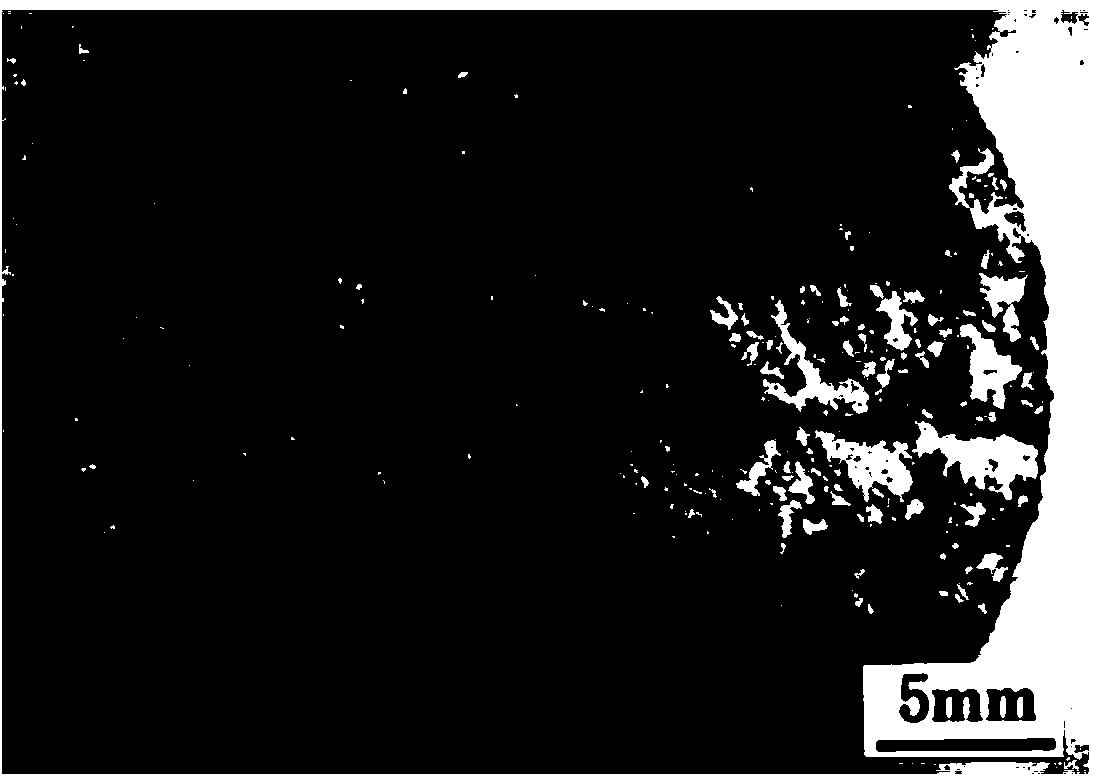

Image

Examples

Embodiment 1

[0051] A preparation method of a laser cladding titanium alloy surface self-lubricating coating, comprising the following steps:

[0052] 1) Pretreatment of the surface of the titanium alloy substrate to be clad: remove the oxide film on the surface of the titanium alloy substrate to be clad;

[0053] In this embodiment, the material of the titanium alloy substrate is TC4. The specific method for removing the oxide film on the surface of the TC4 titanium alloy substrate to be clad: first use 400# metallographic sandpaper to polish the surface to be clad, then immerse in 10% NaOH solution for 3 minutes, take it out and wash it in distilled water, acetone and alcohol in turn Ultrasonic cleaning and final drying;

[0054] In order to prevent the surface to be clad from rapid oxidation again, after removing the oxide film on the surface to be clad, the surface to be clad after removal of the oxide film should be subjected to passivation treatment. In the embodiment of the present...

Embodiment 2

[0067] A method for strengthening the surface of a laser cladding titanium alloy, the difference from Example 1 is:

[0068] 1) The material of the titanium alloy substrate is TC1; when removing the oxide film on the surface of the titanium alloy substrate to be clad, use 1000# metallographic sandpaper to polish the surface to be clad, and then immerse it in 6% NaOH solution for 4 minutes.

[0069] 2) The cladding material is Ni60 alloy powder. The particle size of the Ni60 alloy powder is 50-100 μm.

[0070] 3) The thickness of the coating layer is 1.5mm. The drying temperature is 120° C., and the drying time is 0.9 hours.

[0071] 4) Using ML-108 type CO 2 The laser irradiates the coating on the surface of the titanium alloy, and the laser cladding process parameters are: laser output power P=2kW, beam scanning speed V=1.0mm / s, and spot size D=3mm. During the laser cladding process, argon gas is used to protect the molten pool, and the flow rate of argon gas is 30L / min. ...

Embodiment 3

[0075] A method for strengthening the surface of a laser cladding titanium alloy, the difference from Example 1 is:

[0076] 1) The material of the titanium alloy substrate is TC9; when removing the oxide film on the surface of the titanium alloy substrate to be clad, use 1000# metallographic sandpaper to polish the surface to be clad, and then immerse in 8% NaOH solution for 2 minutes.

[0077] 2) The cladding material is prepared by Ni60 alloy powder and TiC powder at a volume ratio of 50:50. The particle size of the Ni60 alloy powder is 50-100 μm; the particle size of the TiC powder is 50-100 μm.

[0078] 3) Thickness of coating layer: 0.6mm. The drying temperature is 120° C., and the drying time is 0.5 hour.

[0079] 4) Using ML-108 type CO 2 The laser irradiates the coating on the surface of the titanium alloy, and the laser cladding process parameters are: laser output power P=5kW, beam scanning speed V=12mm / s, and spot size D=6mm. During the laser cladding process, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com