Manufacturing method of transient voltage suppressor chip having tunneling effect

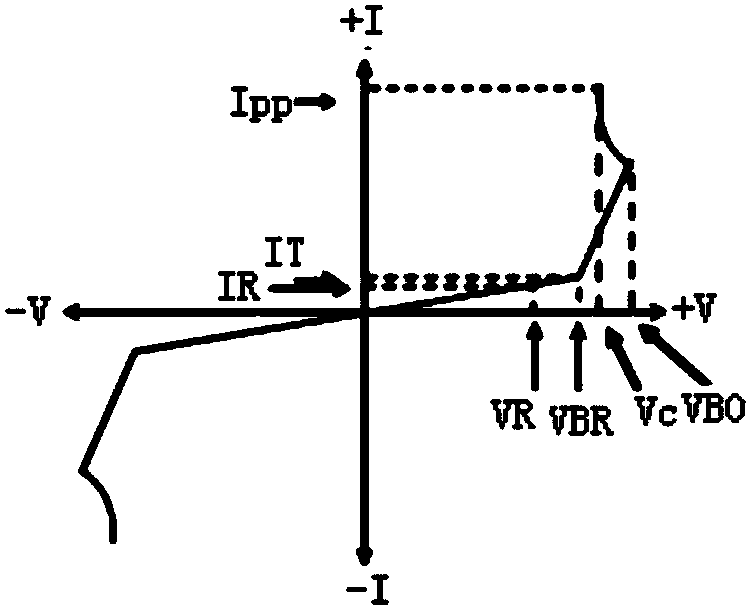

A technology of transient suppression and tunnel effect, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problem of low withstand voltage, achieve the effect of reducing Vc value and realizing tunnel effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of the present invention will be described in further detail below through specific embodiments in conjunction with the accompanying drawings.

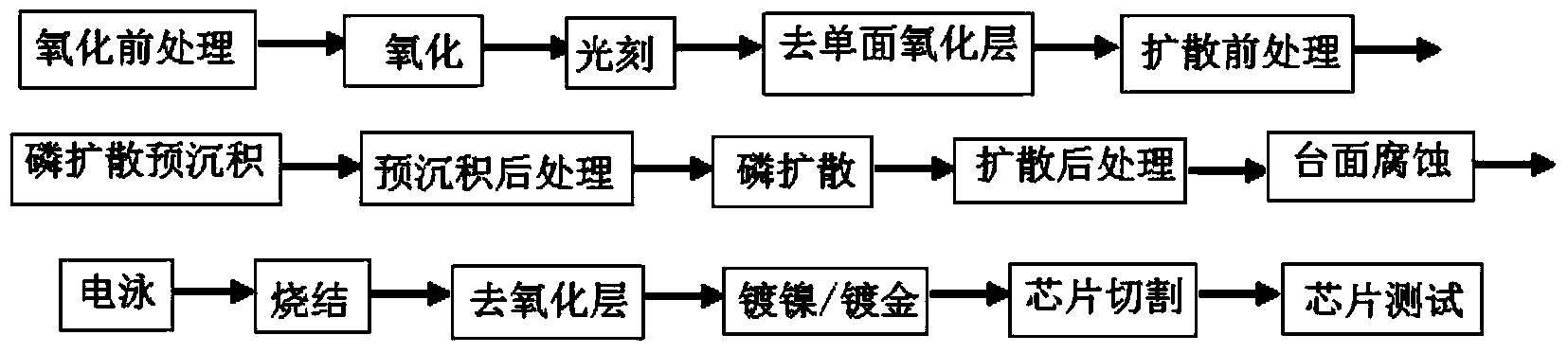

[0030] Please refer to figure 1 , the flow chart of the method for manufacturing a chip with tunnel effect characteristics disclosed by the present invention mainly includes the following steps:

[0031] 1) Pre-oxidation treatment:

[0032] Chemically treat the surface of silicon wafers through electronic cleaning agents, deionized water cleaning and other processes;

[0033] 2) Oxidation:

[0034] Clean the original silicon wafer, and grow a layer of oxide layer as a mask in an oxidation furnace at 1100-1200 ° C to prevent the boron diffusion source from entering the N+ surface and groove;

[0035] 3) Photolithography:

[0036] Apply glue, expose, and develop the oxidized silicon wafer to form a mesa pattern;

[0037] 4) Remove the oxide layer on one side:

[0038] Remove the oxide layer on one sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com