A preparation method of fluorosilicon polymer and its application to the sealing and protection of stone cultural relics

A fluorosilicon polymer, quality technology, applied in the direction of coating, can solve the problems of poor adhesion of organic fluoropolymers, poor low temperature resistance, high price, etc., and achieve excellent waterproof performance, good light transmission, and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

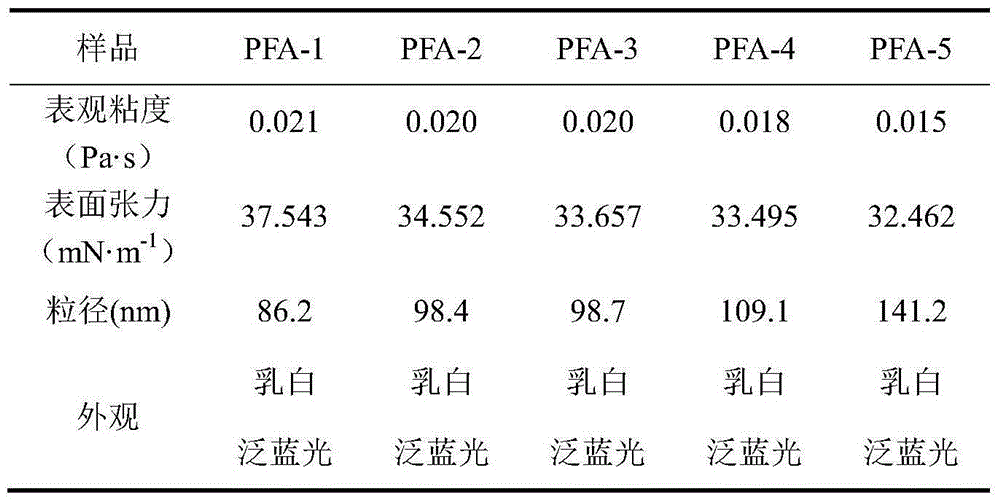

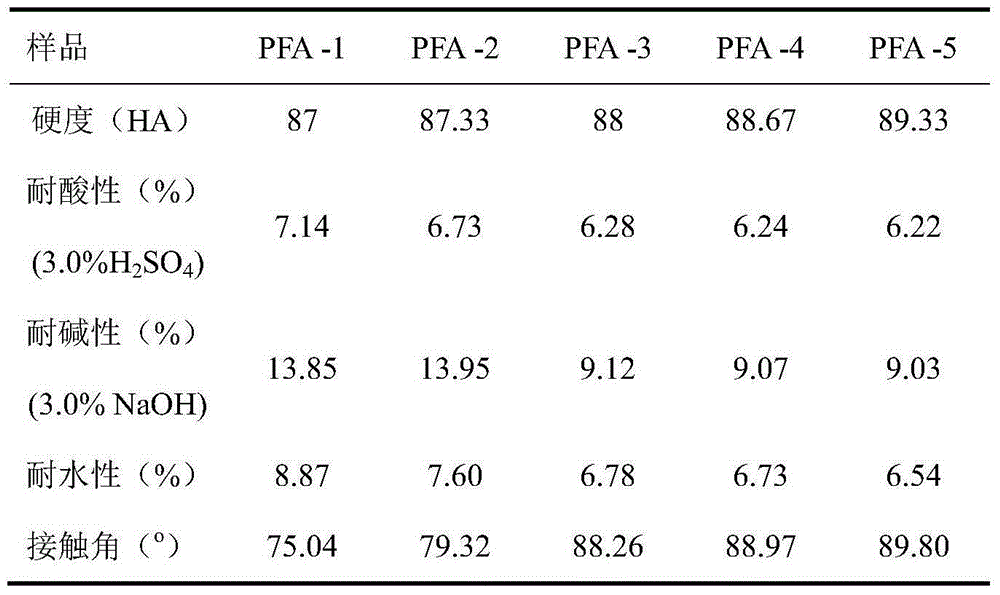

Embodiment 1

[0033] Add 0.572g OP-10, 0.286g SDS and 25g deionized water into a 500mL four-neck flask equipped with a stirrer, reflux condenser, thermometer and feeding device, stir well until dissolved; add 10gMMA, 13.33gBA, 0.467gAA and 2.380 gDFMA, 40°C rapid stirring pre-emulsification for 1.5h; take another 500mL four-necked bottle equipped with a stirrer, reflux condenser, thermometer and feeding device, add 0.190g OP-10, 0.095g SDS and 11.633g deionized water, fully Stir until dissolved, add 2.380g modified tetraethyl orthosilicate (TEOS) sol, 40℃, 1.5h; then add 0.157g Na dissolved in 5g deionized water 2 HPO 4 Buffer and 0.057g initiator KPS solution dissolved in 5g deionized water, and shell monomer pre-emulsion mass Raise the temperature to 70°C; after the blue phase appears in the system, continue to raise the temperature to 80°C, and at the same time add the remaining pre-emulsion and 0.057g of the initiator KPS solution dissolved in 10g of deionized water dropwise, and contr...

Embodiment 2

[0035] In a 500mL four-neck flask equipped with a stirrer, reflux condenser, thermometer and feeding device, add 0.619g OP-10, 0.309g SDS and 30g deionized water, stir well until dissolved; add 10gMMA, 13.33gBA, 0.467gAA and 4.759g gDFMA, 45°C rapid stirring pre-emulsification for 1h; take another 500mL four-necked bottle equipped with a stirrer, reflux condenser, thermometer and feeding device, add 0.206g OP-10, 0.103g SDS and 12.183g deionized water, stir well To dissolve, add 2.380g modified tetraethyl orthosilicate (TEOS) sol, 45°C, 1h; then add 0.170g Na dissolved in 5g deionized water 2 HPO 4 Buffer and 0.062g initiator KPS solution dissolved in 5g deionized water, and shell monomer pre-emulsion mass Raise the temperature to 75°C; after the blue phase appears in the system, continue to heat up to 80°C, and simultaneously add the remaining pre-emulsion and 0.062g of the initiator KPS solution dissolved in 10g of deionized water dropwise, and control the dropping rate fo...

Embodiment 3

[0037] Add 0.666g OP-10, 0.333g SDS and 35g deionized water into a 500mL four-neck flask equipped with a stirrer, reflux condenser, thermometer and feeding device, stir well until dissolved; add 10gMMA, 13.33gBA, 0.467gAA and 7.139g gDFMA, 50°C rapid stirring pre-emulsification for 1h; take another 500mL four-necked bottle equipped with a stirrer, reflux condenser, thermometer and feeding device, add 0.222g OP-10, 0.111gSDS and 12.736g deionized water, stir well To dissolve, add 2.380g modified tetraethyl orthosilicate (TEOS) sol, 50℃, 1h; then add 0.183g Na dissolved in 5g deionized water 2 HPO4 buffer and 0.067g initiator KPS solution dissolved in 5g deionized water, and shell monomer pre-emulsion quality Raise the temperature to 80°C; after the blue phase appears in the system, keep the temperature at 80°C, and add the remaining pre-emulsion and 0.067g of the initiator KPS solution dissolved in 10g of deionized water dropwise at the same time, and control the dropping rate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com